Customer application examples of 3D printed parts

More than 5000 active customers worldwide reduce costs with wear-resistant 3D printing solutions

From piano keys to parts for old tractors, igus® has been manufacturing 3D printed parts for customer for years now. No longer do we have to allow machines and parts to become obsolete, we can now recreate components that are no longer manufactured. We can also now look at a worn part and try and re-create it in 3D materials and it becomes a moveable part.Have a look at the various applications below.

Would you like more information about the our 3D printing or do you need an individual consultation? Our experts will be happy to get in touch with you.

Contact an expert

Examples of 3D printed Applications

Gears in the fire-extinguishing vehicle

Gears in the searchlight

Gears for a blood-testing device

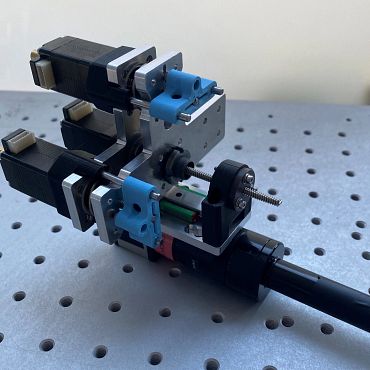

Clamps for the microscope camera

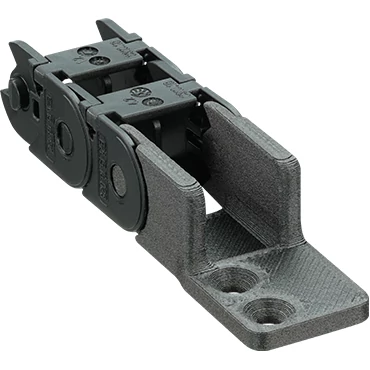

More about the mounting bracket for energy chains

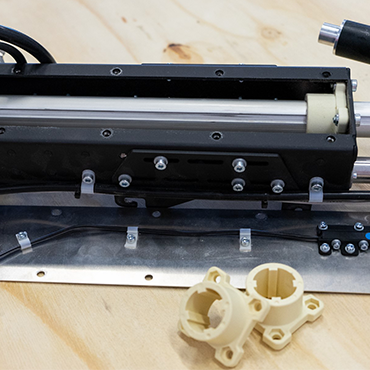

Profile saw device

Special sliders in rope-free lift

Bevel gear drive in a medicine dispenser

More about the gear printed in 3D

Finger joints in an exoskeleton

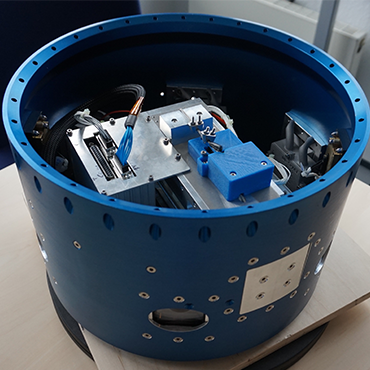

P2M plain bearings in a waste sorting robot

More about 3D printed components in space

Ball bearings for a 3D printed vehicle

Lead screw in a fully automated coffee machine

Component for a rear wing

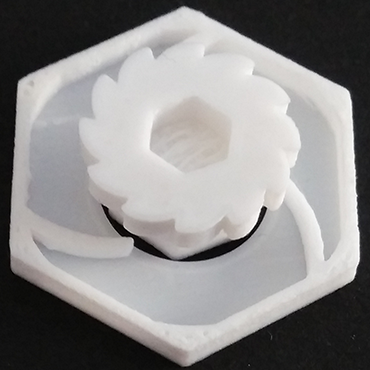

Injection mould for ball bearing cage

Prototype plain bearings from the 3D printer

Glide pad adapter clip for igus energy chains

3D printed mechanical clockwork

Piano string hammers

Gear in a tractor

Plain bearing in a pram

More about replacement gears in an e-bike gearbox

Cross-threaded shaft in a winding machine

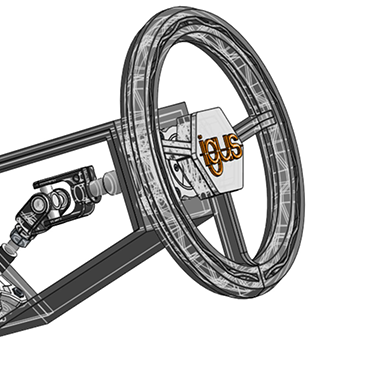

Special sliders in the steering wheel accelerator ring

Vintage speedometer

Pinions for a racing car motor

Gears in an e-car charging station

Sliding plates for water mowing machines

Sprockets for e-bikes

Grippers for packaging

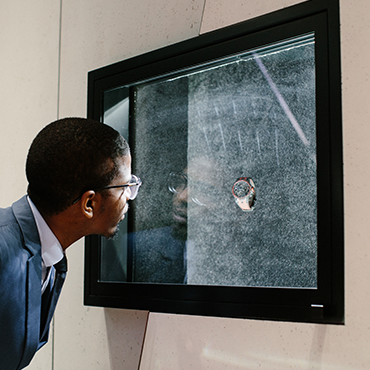

Grippers for the Corona testing station

Special bearings for a camera dolly

More about the 3D printed rudder bearing