Wear-resistant clockwork parts from the 3D printer

- What was needed: components for mechanical clockwork

- Manufacturing method: filament extrusion (FDM)

- Requirements: high abrasion resistance, good mechanical properties, detail accuracy

- Material: iglidur® I150

- Industry: model making

- Success for the customer: improved wear resistance, significantly longer component service life

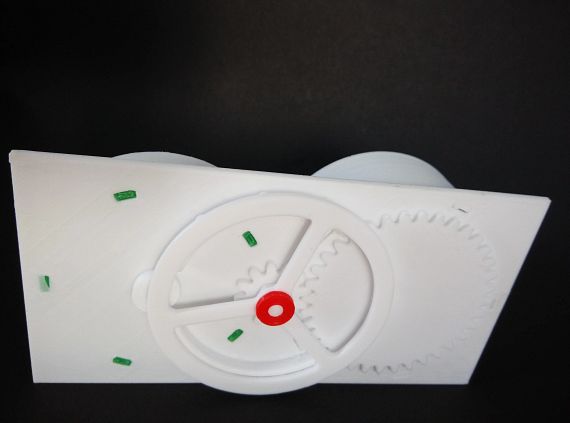

As part of a Jugend Forscht project, Kai Schmidt-Brauns constructed a completely 3D-printable clockwork and compared a mathematically calculated profile curve of a mechanical clockwork escapement with an empirically determined profile curve. To test each profile curve, he printed the mechanical clockwork based on his mathematical model. In addition to the experiments with components made of conventional PLA, Schmidt-Brauns tested the different profile curves with components made of the iglidur® I150 tribofilament. Due to the tribologically optimised filament, components that are subjected to particularly high mechanical loads were able to achieve a significantly longer service life and a more regular run than parts made of conventional PLA.

More about iglidur I150

Problem

In order for a mechanical clockwork to run accurately, the geometry of all components of the mechanism must be precisely determined and the friction between moving parts must be kept as low as possible. The aim of Kai Schmidt-Brauns' project was to design an escapement mechanism for the 3D printable clockwork and subsequently determine its geometry with a mathematical model. Although the mathematical model led to a more regular movement of the clockwork, the question arose as to other ways of making the clockwork even more accurate. In addition, in the tests with 3D-printed components made of conventional PLA, the heavily stressed parts, such as the ratchet (consisting of ratchet wheel and ratchet rim) in the lift, did not have a particularly long service life.Solution

After the tests with the clockwork made of conventional PLA, Kai Schmidt-Brauns replaced critical components with specimens printed from the igus® iglidur® I150 tribofilament. In the comparison, it was noticeable that the sliding and static friction between the components made of iglidur® I150 is significantly reduced. In addition, thanks to the high wear resistance of the igus material, the service life of the ratchet could be increased, as well as a more regular movement of the escapement.A precise clockwork completely from the 3D printer

Jugend Forscht is a German competition for young researchers from the 4th grade up to the age of 21. Participants can work on and submit problems of their own choice in the fields of mathematics, computer science and natural sciences. As part of this competition, Kai Schmidt-Brauns from Wolfsburg first set up a mathematical model to determine the exact geometry of the components of a 3D printable escapement mechanism. This involved in particular the profile curve of the profile wheel, which he was able to calculate from well-defined parameters. The escapement of a watch is the part that determines the accuracy of the watch. The escapement mechanism "inhibits" the gear train at regular intervals, for example with the help of a pellet fork, and ensures that one minute in the clock also corresponds to one minute and does not last sometimes 61 and sometimes 55 seconds. In the next step of the project, Kai Schmidt-Brauns compared the calculated profile curve with an empirically determined profile curve. He found that the movement with the calculated profile curve had a more regular rate than the empirically determined profile curve.

More precise motion with iglidur® I150

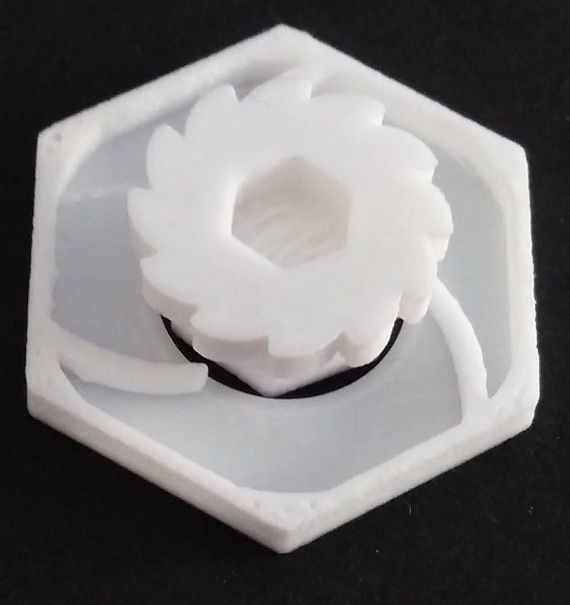

In addition to comparing the mathematical formula and the empirically determined profile curve, Kai Schmidt-Brauns tested the escapements with different material. The choice fell on the iglidur® I150 tribofilament. With a bed temperature of 40°C, a printing speed of 30mm/s at a layer height of 0.1mm and an extruder temperature of 250°C, the student achieved the best results with the filament from igus. Compared to the conventional PLA, he was also able to detect a much more regular escapement during a test run. In addition to the results in the escapement, the tribologically optimised filament was able to provide an improvement in heavily stressed components with its wear resistance. The ratchet rim of the ratchet (see picture), which is located in the winding mechanism of the clockwork, had to be replaced significantly more often when using conventional PLA than with iglidur® I150. Furthermore, through tests with a spiral spring printed from iglidur®I150, he was able to record a higher toughness and pliability compared to the one made from conventional PLA.

igus® tribo filaments for more service life of the applications

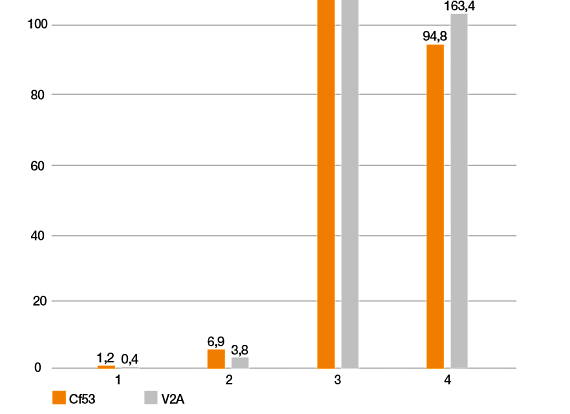

Besides iglidur® I150, igus® offers many other tribologically optimised filaments for 3D printing. All have in common their high abrasion resistance for gliding applications. iglidur® I150 can be processed very easily, just like PLA and PETG filaments. In the wear test from igus®' in-house test laboratory, the igus® tribofilaments perform up to 50 times better than conventional plastics such as PLA and ABS (see picture). It is also food compliant according to EU Regulation 10/2011 and therefore suitable for appropriate applications in the food and packaging industry. The all-rounder filament is particularly suitable for novice printers due to its easy processing. The 3D printing service is also available at any time with a delivery time of 1-3 days if expert help is needed.Go to 3D printing service

Other application examples for 3D printed components can be found here:

All customer applications at a glance