3D printing component for the removal of "uncooperative" space debris

The application at a glance:

- What was needed: two NEMA11 stepper motors, 3D printed nuts made of iglidur J260 tribofilament, tribo-tape plastic liner made of iglidur V400

- Manufacturing method: filament extrusion (FDM)

- Requirements: component temperature and pressure resistance; durable, lightweight design; reliable ejection mechanism

- Material: iglidur J260

- Industry: aerospace and aviation

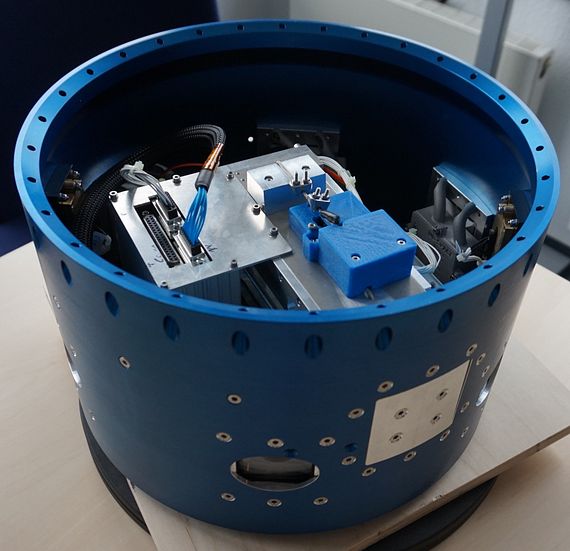

- Success through collaboration: stepper motors, lead screw, and plastic liner guarantee reliable ejection

in order to successfully collect space debris, test data on part must first be collected on the movement of the space. To do this a team of six students from the University of Bremen and the Bremen University of Applied Sciences developed a rocket module that uses sensors and cameras to record the movement and position of objects in space using an ejected test body. Two lead screw drives were used in parallel for the ejection mechanism. The lead screw drives were exposed to extreme loads, such as temperatures of +200°C due to air friction, and had to function reliably. This is where the igus components came into play: The drylin lead screw drives were each driven by a NEMA11 stepper motor. The bracket for the test body was attached to a 3D-printed lead screw nut made of the iglidur J260-PF tribofilament. A plastic liner was used to ensure that the test body slips out of the bracket and moves away from the rocket.

Contact an expert

Problem

In the UB-Space project, six students worked on the problem of "collecting" space debris again and disposing of it. In order to implement this project, however, the team led by Maren Hülsmann needed sufficient test data concerning the movement of objects in space. To do this, they wanted to drop a cube-shaped test body into the thermosphere and observe it with cameras and sensors to collect the real data they needed there. The team needed reliable materials for the components of the ejection mechanism that would drop the object from the rocket. It had to meet the special requirements of space, such as limited installation space and weight, as well as energy consumption and good resistance to pressure and temperature.

Solution

With the materials from igus optimised for sliding applications, the team quickly found suitable components for the planned ejection mechanism. This consisted of two NEMA 11 stepper motors, each of which is connected by a coupling to a lead screw. This structure was mounted on the rocket wall with a 3D-printed nut made of iglidur® J260-PF. The running surface of the ejection chute was lined with tribo-tape made of iglidur® V400, so that the test object could be ejected without friction.More about iglidur® J260-PF

Protection of the space environment

It is not only on earth that a major waste problem exists. With over 1,000 satellites orbiting the blue planet, after decades of space travel there is also a whole lot of rubbish in space. There are now more than 30,000 objects in the earth's orbit that can be very dangerous for active satellites. These objects can reach speeds of up to 25,000 km/h and thus release high destructive energies in the event of a collision. The goal of the UB-Space project is to collect the waste in space and dispose of it properly. The six-member interdisciplinary team consisting of students from the University of Bremen and the Bremen University of Applied Sciences has set itself the task of analysing the movement of these so-called "uncooperative objects" in space in order to enable an appropriate waste collection campaign. For this purpose, a test body installed in a rocket module is released into the thermosphere. The position and movement of the so-called "Free Falling Unit" (FFU) is precisely recorded by sensors and a camera system after ejection, thus creating a real basis for calculation for the team.

igus® components prove themselves in space

To be able to eject it reliably at the right time, the UB-Space team developed a special mechanism for the rocket module. However, the use of mechanics in space is very different from ordinary operations on earth. According to marine engineering student Oliver Dorn, energy consumption as well as weight and installation space are limited. In addition, air friction results in temperatures of up to +200°C. After several tests, the team decided on a drive system consisting of two lead screws used in parallel to extend the unit in which the FFU is located. The opening for the unit is a flap that is blown off beforehand. The stainless steel lead screws from the igus® drylin® range are each driven by a NEMA 11 stepper motor. In doing so, they cover a distance of 150 millimetres at a high torque and low speed of 3 cm/s. The opposite side of the structure is attached to the rocket wall with a 3D-printed nut made of iglidur® J260-PF. So that the FFU can be ejected as smoothly as possible, the ejection shaft is lined with the tribo-tape plastic liner made of iglidur® V400. The materials from igus are ideally suited for precisely such a use, as their optimum sliding properties ensure tilt-free and energy-efficient ejection. They are also resistant to pressure and temperature and have a low weight, which was crucial for the special construction requirements.

3D printing for small and large projects

In addition to the iglidur® J260-PF tribofilament used, igus® offers other filaments for 3D printing. As the name suggests, the filaments are tribologically optimised and suitable for any application where friction and wear are a concern. It is in just such applications that customers benefit from a long service life and temperature resistance of up to 180°C. The printing process allows complicated geometries to be produced in a single operation. The additive process is particularly well suited to special parts for prototypes or small volumes. The production costs are lower and there is therefore no minimum quantity.

Go to the filament shop

Other application examples for 3D printed components can be found here:

All customer applications at a glance