Replacement gear from the 3D printer

What was needed: replacement gear for a tractor motor

Production method: selective laser sintering

Requirements: high wear resistance, good sliding and mechanical properties

Material: iglidur I3

Industry: utility vehicles

Success from the collaboration: manufacturing costs are one-tenth of those for conventional production methods, complex part made in one piece, improved abrasion resistance

The application at a glance:

the igus cleaning team uses a tractor for such work as gritting and transport. The gear serving as a starter for the tractor's motor was so worn out after a while that the tractor could no longer start. The manufacturer was unable to provide a replacement, so the tractor remained out of service. After about six months of inactivity, it was to be scrapped. However, shortly before it was, the 3D printing team intervened and was able to trace the worn and broken gear and print it within a matter of hours. The tractor now works reliably again thanks to the gear made of iglidur I3, which has significantly better sliding properties and greater wear resistance than the previously installed gear made of conventional plastic.

Production method: selective laser sintering

Requirements: high wear resistance, good sliding and mechanical properties

Material: iglidur I3

Industry: utility vehicles

Success from the collaboration: manufacturing costs are one-tenth of those for conventional production methods, complex part made in one piece, improved abrasion resistance

The application at a glance:

the igus cleaning team uses a tractor for such work as gritting and transport. The gear serving as a starter for the tractor's motor was so worn out after a while that the tractor could no longer start. The manufacturer was unable to provide a replacement, so the tractor remained out of service. After about six months of inactivity, it was to be scrapped. However, shortly before it was, the 3D printing team intervened and was able to trace the worn and broken gear and print it within a matter of hours. The tractor now works reliably again thanks to the gear made of iglidur I3, which has significantly better sliding properties and greater wear resistance than the previously installed gear made of conventional plastic.

Contact and expert

3D printing options

3D printing material shop

Visit the shop

3D printing at igus®

3D printed gears

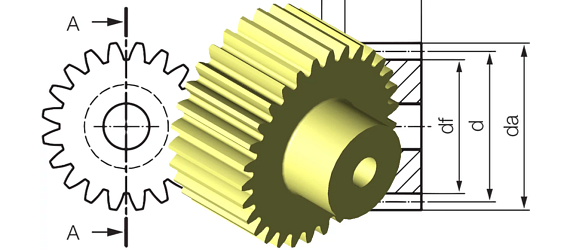

Simply configure gears yourself

igus offers different options for printing a gear. For example, design engineers can configure the required gears with the igus gear configurator and then order them from igus directly. Find out exactly how this works here. Alternatively, an existing CAD model can be uploaded in the 3D printing service and commissioned with the appropriate igus material and manufacturing method.Go to 3D printing service

Calculate gear service life

In the igus test laboratory, different load tests are carried out. All igus® products are put to the acid test to make sure online tools are reliable and informative. One of these tools is the gear service life calculator, which determines the service life of gears made of iglidur® I3 or iglidur® I8, depending on application-specific load data. This makes it easy to check whether the material is suitable for your own application and when you should change the gear before it fails.To the service life calculator

Other application examples for 3D printed components can be found here:

All customer applications at a glance