From prototype to final product - ready-to-install ball bearings from the 3D printer

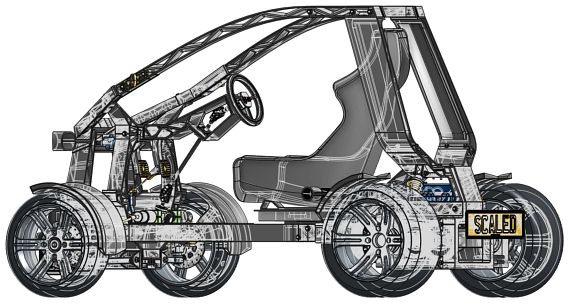

The company Scaled 3D based in the UK has developed a four-wheeled vehicle in its “Chameleon” project that consists exclusively of 3D-printed components. During vehicle tests, the steering system design was not ideal. In order for the application to remain fully 3D printed, the company began looking for a tough, wear-resistant material that would be more suitable for the bearing points. After various tests in large and small and formats with iglidur® I150 tribofilament, the development team finally designed a five-part plain bearing that had very little clearance and was significantly more abrasion-resistant than bearings made of conventional plastic.

Would you like more information about the our 3D printing or do you need an individual consultation? Our experts will be happy to get in touch with you

Would you like more information about the our 3D printing or do you need an individual consultation? Our experts will be happy to get in touch with you

Contact an expert!

Problem

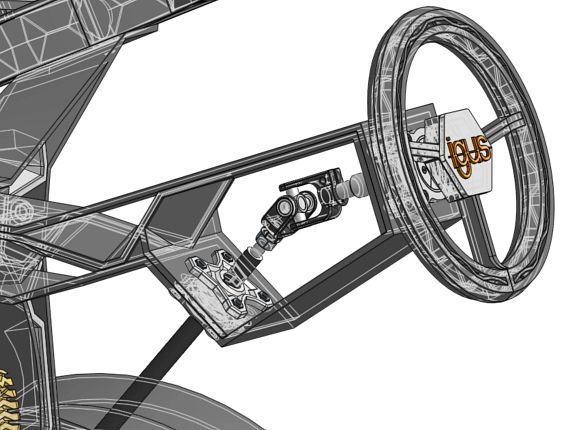

The vehicle's steering system had too much clearance and quickly became imprecise. It also ran the risk of wearing out quickly. So steering bearings with much less clearance that would fit into the existing shape of the rest of the vehicle had to be made. Plain bearing depth was not to exceed 20mm. The lower of the two bearings also had to have a split inner ring to allow mounting with the steering column, which has two sets of radial bolts at each end. The components also had to have significantly greater strength than the previously installed bearings made of standard PLA.Solution

Scaled 3D found the perfect material for its "Chameleon" project in the tribologically optimised iglidur® I150-PF tribofilament. The filament is very easy to process in a large-volume printer and offers good mechanical properties in terms of strength, toughness and layer adhesion in sliding applications. The bearing was converted into a five-piece ball bearing that was initially tested as a prototype. During the tests, the clearance in the bearing was very low under eccentric loads during rotation.The "Chameleon" project - individual, sustainable application

The main goal of the "Chameleon" project from the UK was to develop a vehicle that comes entirely from the 3D printer. The idea behind the project was the change from mass production to fast, customer-specific production. At the same time, no-tool additive manufacturing was to allow recycled material to be used. According to Scaled 3D, it will be possible to use 100% recycled material in 3D printed vehicles and structures in the future. So far, the Chameleon team has managed to work with 30% recycled material in the first prototype of 2020. The speed with which parts can be 3D-printed is of special benefit to this project: a maximum of 83 minutes printing time for a large part (1.375 kg) meant that these parts could be drawn, printed and tested on the same day. The great speed advantage over such processes as milling and injection moulding had a very positive influence on the freedom of vehicle development, which was supported by the design freedom in the geometry of the parts.

The path to the right bearings

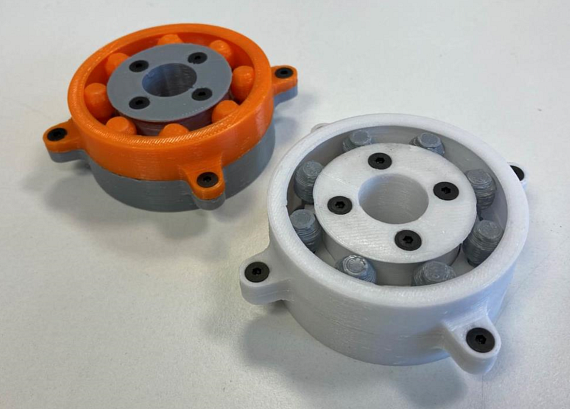

In order to get an overview of the iglidur® I150 tribofilament's tribological properties, the company first tested the components in a small format. First, nested cylinders were printed, their untreated surfaces already of very good quality compared to other materials. Parts were then printed in a large format and their good surface quality was among their impressive features. The ball bearing to be replaced was then reprinted from iglidur® I150. The I150 races and the ball bearing cage proved to be good slide partners for low-friction operation. In the end, a five-piece ball bearing was created.

Large-format 3D printing at igus®

The all-rounder among the igus® tribofilaments - iglidur®I150

During the tests on the iglidur® I150 ball bearing, the clearance was very low under eccentric loads during rotation. A double bearing system was then developed to fit into the Chameleon steering system. According to Scaled 3D, the print quality of iglidur® I150 bearings is comparable to that of ASA and much better than conventional PLA. Despite a layer height of 1mm, the surface finish was very good. In addition to the good component quality, the company is also pleased with the easy assembly of the parts. The tribofilament is suitable for both small applications and projects with the large-scale printer. It has good mechanical properties and is therefore suitable for most applications and 3D printers. iglidur® I150 is also food-compliant according to EU Regulation 10/2011 and is suitable for applications in the food and packaging industries.Further information about iglidur® I150

Other application examples for 3D printed components can be found here:

All customer applications at a glance