Huge 3D printed components with optimised sliding properties and excellent service life3D printing service for components of up to 1m

3D printing service for components of up to 1m

Optimised sliding properties and excellent service life

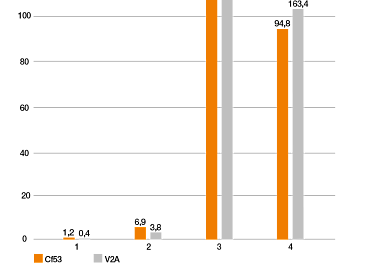

The large-format 3D printer can be used to manufacture components of up to 1m in a single printing process. The 3D print filaments, which igus developed specifically for mechanical engineering, are up to 50 times more abrasion-resistant than ABS, PETG or PLA. The large-format components made of igus high-performance polymers can be used without problems in large-scale mechanical engineering. Possible areas of application include jig construction, special machine construction and packaging technology.The 3D-printed components fare well in direct comparison with machined parts because of their lightweight design, greatly reduced material requirements (up to 85%) and cost-effective manufacture. For good surfaces and precise components, sub-areas can be reworked.

Do you have an application that requires large-format components? Simply upload your CAD models and order your component online from the 3D printing service.

Go to 3D printing service

DIY large-format 3D printer

Download design data free of charge

Design and construction of the 3D printer

Learn more

Manufacturing large-format food-safe components

iglidur I150

iglidur I150 is the easiest tribo-filament® to process - it is suitable for all commercially available 3D printers and can be processed just as easily as regular filaments such as PLA and PETG. iglidur I150 is also available on 8kg filament reels and is therefore suitable for the manufacture of large components in large-scale printers.Thanks to compliance with EU 10/2011, iglidur I150 is suitable for contact with food and is accordingly proving itself in applications in the food and packaging industry. The only restrictions are in the maximum permanent application temperature of 65°C and for highly dynamic applications.

iglidur I150 in the shop

iglidur I150 material data sheet and approval for use with food

Large wear-resistant parts in lightweight construction

Efficient use of materials reduces weight and costs

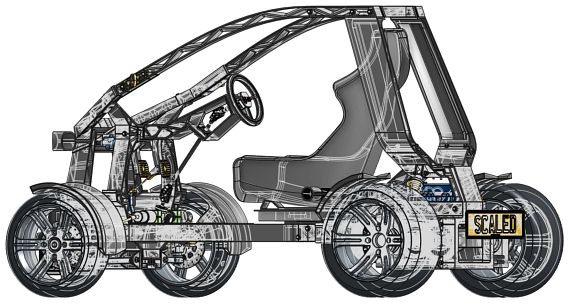

Application example in the vehicle printed in 3D

For the "Chameleon" project, UK-based Scaled 3D wanted to touch up the steering of the vehicle that was entirely printed in 3D. With the conventional plastic there was too much play at the beginning and the steering became very inaccurate. With the igus tribofilament iglidur I150 and a newly developed ball bearing, the abrasion resistance and accuracy of the steering system could be significantly increased.

Ball bearings from the large-volume 3D printer