Cost effective manufacture of a complex drive unit for a medicine dispenser

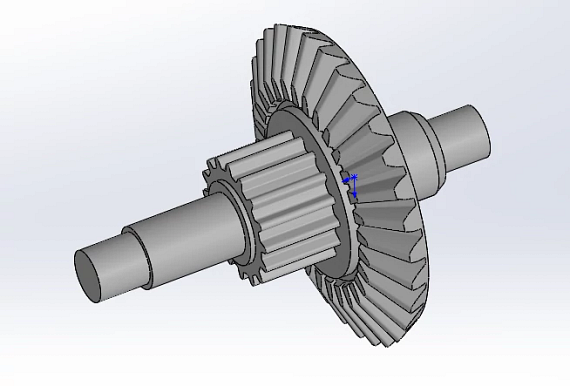

- What was needed: A complex bevel gear and a drive element in the separation unit

- Manufacturing method: Selective laser sintering

- Requirements: Small installation space, no maintenance & service life longer than five years

- Material: iglidur® I3

- Industry: Medical sector

- Success through collaboration: Complex components manufactured cost-effectively and quickly & long service life

Contact an expert

The application at a glance:

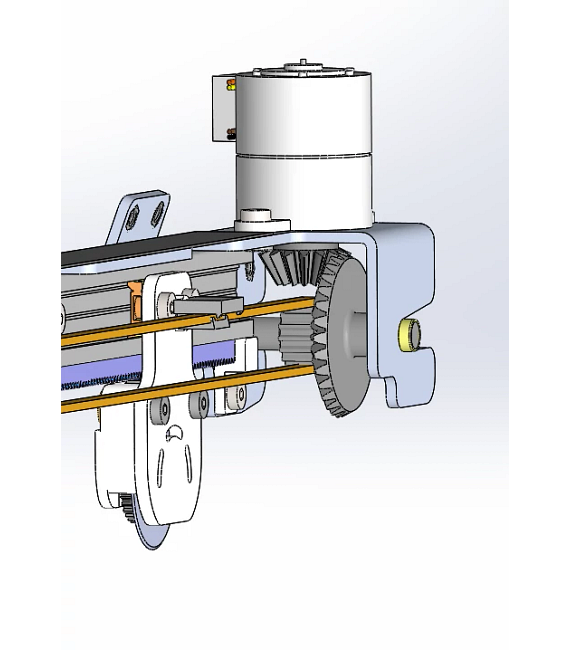

JDM Innovation GmbH required a drive assembly consisting of bevel gear and linear drive for the separating unit in a dispenser for personally packaged medicines. The dispenser was to dispense individual medicine bags according to a previously programmed medication schedule. This required reliable, maintenance-free components that would fit into the very small installation space and would provide a service life of more than 5 years. But the developers did not get very far with standard injection moulded gears, which entailed time-consuming individual assembly, preventing dosing unit series production. The problem was solved with the igus® 3D printing service. The complex bevel gear and linear drive that was needed was developed as a CAD design according to the individual requirements in the installation space. The parts were then manufactured using selective laser sintering and were installed immediately. So far, the separation units and gears have been installed in about 400 devices, dispensing medicines up to five times a day.

Using iglidur® I3 to create a wear-resistant part

The integrated solid lubricants mean that iglidur i3 requires no maintenance or lubrication, which is particularly advantageous for applications where good hygienic conditions play a major role. Besides being hygienic, components made of iglidur i3 are well suited to any applications subject to wear. Tests from igus's own laboratory show that abrasion resistance is 3 to 30 times better than that of conventional materials for laser sintering. The components also have very high mechanical strength and are therefore especially well suited to the manufacture of spur gears, bevel gears, drive nuts, special sliders, and spherical bearings. A gear test confirmed this. Spur gears made of iglidur i3 had five times the service life of POM milled plastic gears.A 3D printed gear expert, igus offers various online tools for configuring individual gears. The service life calculator shows a realistic indication of gear service life based on tests performed in the igus test laboratory. In the gear and rack configurator, components can be designed easily according to individual requirements. In the online calculation, you immediately receive the exact unit price for your component.

More about iglidur® I3

Problem

The limited installation space in the dispenser made optimal component arrangement difficult. Drive unit installation was so complicated that it could not be easily solved with standard injection moulded gears. The cutting blade's transport belt had to be kept under tension, which would damage the electric motor's drive shaft, so drive element arrangement was unusual. Installing standard gears would have resulted in compromised components and costly one-off assemblies. But the dispenser was intended for series production. The components also had to have a service life of more than five years.Solution

The design freedom of additive manufacturing allowed adapting the components precisely to the requirements of the small installation space. The parts produced from the iglidur® I3 SLS powder with selective laser sintering were installed and tested directly. The iglidur® I3 SLS powder was developed specifically for laser sintering and has very good tribological properties. This allows component service life expectancy to be up to 30 times that of components made of conventional plastic. Parts could also be produced much faster than would have been the case with injection moulding. The delivery time is usually two to three days - for urgent projects, igus® can also ship components within 24 hours.Complex geometries printed simply and in a very short time

The bevel gear assembly in the dispenser's separation unit was subject to a variety of requirements, including tight installation space. A belt moves a rolling blade that has a drylin® N miniature guide as linear guide. The 3D printed shaft is guided in two igus® bearings in the metal sheet. Installing standard gears would have resulted in installation space compromises and costly one-off assemblies. But dispenser series production was planned, so a more sensible alternative was needed. Additive manufacturing was a suitable solution to the problem. The individually produced CAD design for the bevel gear could be easily implemented in selective laser sintering. This meant that the drive unit could be installed in the dispenser's small installation space without compromise. In addition to the precise, detailed component fit.

More igus products in application:

Other application examples for 3D printed components can be found here:

All customer applications at a glance