Replacement rudder bearing 3D printed

The lower rudder bearing of an Albin Delta sailing boat had broken and needed to be replaced. However, the customer could not get a spare part without problems as the manufacturer of the boat went out of business several years ago. In addition, the dimensions used in the original design are not common nowadays, and with the split design of the bearing chances of obtaining an alternative spare part are very low.

- What was needed: a two-piece rudder bearing

- Manufacturing method: selective laser sintering (SLS)

- Requirements: split design, functionality in seawater, good fit

- Material: iglidur® I3

- Industry: ship building

- Success due to cooperation: fast production and delivery within three weeks, more cost-effective by a factor of 20 compared to the alternative made of seawater-resistant metal alloys, improved steering behaviour

Contact an expert

Problem

The rudder bearing of a sailing boat had to be replaced. However, the model Albin Delta or Delta 31, dating from the 1980s, has a special bearing, the design of which is divided into two parts. The bearings are no longer produced due to their unusual size, and the manufacturer doesn't exist any more. Hence, looking for a ready-made alternative proved to be almost impossible. The only solution seemed to be a very expensive production of bearing shells from seawater-resistant metal alloys.Solution

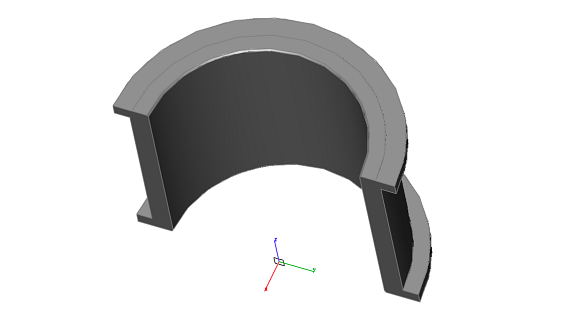

The customer found an inexpensive alternative at igus®. Using the online configurator, they were able to design the basic shape of the rudder bearing and download it as a CAD model. They then expanded the model to include other features, such as a second flange and the division of the bearing typical of the sailing boat. Finally, the finished model was commissioned to be printed in 3D. Just a few weeks later, the replacement bearing arrived, and after a short time, the customer was able to detect a significant improvement in the steering behaviour.Achieving attention to detail with the SLS process

To ensure a stable steering behaviour over time, a rudder bearing with the perfect fit had to be manufactured. This proved a tricky task, as the rudder bearing was subject to a very individual fit due to its unusual dimensions and its division. By using the igus® online configurator, the customer was able to design a plain bearing in a suitable basic shape with the correct tolerances. After a few adjustments, they chose the SLS method for production. Here, a laser selectively melts the SLS powder layer by layer in a powder bed. This process leads to very high dimensional accuracy and combined with the iglidur® I3 SLS powder, enables ideally suited components that require high attention to detail with exact surfaces to be produced

Go to the 3D print configurator

It doesn't always have to be metal - with motion plastics you go further (at a reasonable price)

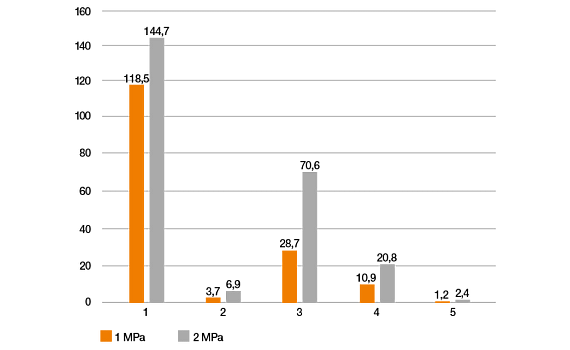

Alternatively, the customer could have resorted to custom manufacturing of bearing shells from seawater-resistant metal alloys. However, this would have been associated with 20 times the costs of the bearing made of high-performance polymers. The materials for 3D printing from igus are tribologically optimised and ideal for applications showing signs of wear. For the application conditions of the rudder bearing, iglidur i3 was suitable as it is a wear-resistant material; for more demanding and durable underwater applications, the igus test laboratory recommends iglidur i8 (see figure). You can find a complete description of the underwater tests here. The 3D-printing service from igus not only offers SLS materials, such as iglidur i3 and i8, but also filaments and other accessories for the additive manufacturing of customised wear parts.

Replacement parts from the 3D printer - vintage cars, sailing boats etc.

One of the biggest advantages of 3D printing is the geometrical freedom that comes with processes that don't require tools. The highlight at igus®: we use our own tribologically optimised materials, which are particularly suitable for printing wear parts. The integrated solid lubricants eliminate the need for external lubrication and regular maintenance. For the speedometer of a vintage car this was the ideal solution both in terms of price and delivery time. It was easy to reconstruct and print a replacement for the worn screw. But 3D printing is not only worthwhile for individual wear parts; the additive process is also suitable for series production.

Further application examples with components printed in 3D

All customer applications at a glance