Additive manufacturing processes at igus®

Additive manufacturing processes are part of digital production. Regardless of 3D printing method, each new component must first be designed as a digital 3D model, which can then be used for production without the need for further component-specific tools. This process offers numerous advantages:

- 3D models can be shared and processed by multiple specialists

- Manufacture can be offered locally: igus® offers 3D printing service worldwide

- Modifications to components can be made quickly and without additional charge,

- Simple geometries and standard components can be designed quickly and easily on free-of-charge software; no previous experience necessary

Contact the expert

With our 3D printing service you can produce wear-resistant plastic components by means of three different processes: SLS, FDM and DLP 3D printing. On this page you will find further information on the respective production methods.

- Selective laser sintering (SLS) 🔽

- Fused Deposition Modelling (FDM) 🔽

- Digital Light Processing (DLP) 🔽

- The manufacturing process in real life 🔽

Selective Laser Sintering (SLS)

In SLS 3D printing, plastic powder is applied in layers with a blade and melted with a laser at specific points where the component is to be produced. This process is characterised above all by its cost-effectiveness, fast production and high dimensional accuracy of the printed components (from ±0.1mm).Further advantages:

- Strength and good layer bonding

- Toughness: elongation at break is greater than 8%

- Intricate components with a wall thickness of up to 0.7mm can be realised

- Worldwide printing service: igus® has laser sintering plants in Germany, China, and the U.S.

Discover the igus SLS powders in the shop

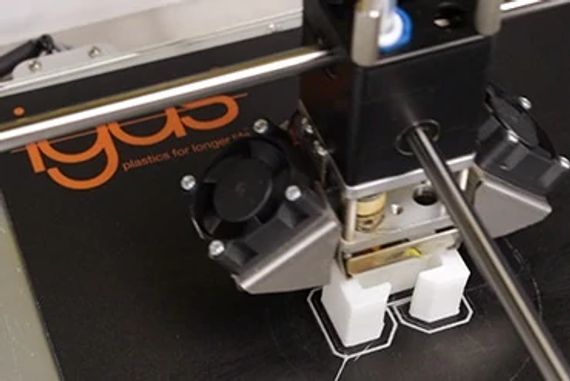

Fused Deposition Modelling (FDM)

FDM is a 3D printing method in which material that can be melted (plastic) is heated and applied layer by layer through one or more nozzles. This method is also referred to as melt strand deposition or filament extrusion. The low purchase price of a filament printer and the usability make FDM the most widely used 3D printing process.Special services at igus:

- Multi-material printing: in the 3D printing service, it is possible to produce parts from up to four different filaments in one printing process.

- Large-format 3D printing: components up to 1 metre in size can be additively manufactured in the large-format 3D printer from igus.

Tip: If you would like to do without support material and require components with a good layer bonding and higher dimensional accuracy (<±0.2mm), the SLS and DLP processes are more suitable than FDM.

Discover the igus tribofilaments in the shop

Digital Light Processing (DLP)

DLP is a 3D printing process in which synthetic resin in a basin is exposed, layer by layer, to UV light, thereby curing or polymerising it. A UV light source strikes an array of mirrors, which reflect the light as two-dimensional layer geometry, shining it onto the material.Advantages:

- High print resolution of up to 35µm

- Isotropic mechanical properties (no strength disadvantages thanks to the layer structure)

- Clean and smooth surface

- Possible areas of application: gears with Tooth Module 0.2 and special components that require intricate recesses, internal channels or the finest holes

A major advantage of 3D printing using the DLP process is the time saved. Unlike the SLA process, in which each dot is lasered individually, the DLP process cures the resin surface by surface, so build time is a fraction of that required for SLA. The resolution is also greatly increased (up to 35µm pixels).

Discover our DLP resin in the shop

The manufacturing processes in practice

The online 3D printing service

Have your prototypes or series printed from wear-resistant igus plastics in one to three days.

More about the 3D printing service

3D printing process in operation

Get an overview of the application areas in which the igus 3D printing service has played a decisive role.

Go to application examples

Digital production

CAD configurators

- Online configuration of lead screw nuts, plain bearings, rollers, gears, racks, and sliding elements

- CAD download in all commonly used file formats

- Direct integration into commonly used CAD software

CAD configurator for components

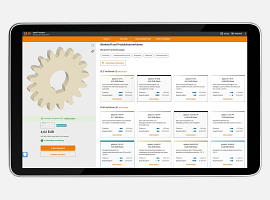

Online 3D printing service

- Quick, easy upload of CAD models

- Prices, price graduation, and delivery time immediately available

- Direct comparison between different additive methods (laser sintering and FDM) and Rapid Tooling (print2mold)

3D printing service

Service life calculator

- For gears and plain bearings

- Calculation takes into account contact with other materials

- All data is based on test results from the igus® test laboratory

- Enviromental impacts considered

Service life calculator for gears