Small installation space, big challenge: gears printed in 3D are the solution

Customised solution for searchlights thanks to the 3D printing service from igus

Police and rescue services often carry out searches at night. Swivelling searchlights on the car roof illuminate the surrounding area so that rescue workers do not have to leave the vehicle. Standby GmbH wants to stand out from competitors by introducing a more powerful, more compact searchlight. However, the small stepper motors of the new design require extremely fine gears, which are very hard to find on the market. The corresponding special components were therefore cost-effectively printed in 3D at igus using the SLS process.- What was needed: suitable gears for the extremely small stepper motors of the remote-controlled searchlight

- Manufacturing method: selective laser sintering (SLS)

- Requirements: small diameter, long service life, little to no wear

- Material: iglidur® i3-PL

- Industry: utility vehicles

- Success through cooperation: increased competitiveness due to the new product design, requirements for wear resistance were exceeded

More about the 3D printing service

Problem

Due to the low installation height of the searchlight, small and powerful stepper motors were selected for the drive units. The standard gears on the market did not fit into the available installation space and were therefore not suitable for the shafts of the stepper motors. In addition, the small installation space requires the gears to have a long service life so that the parts require as little maintenance as possible. Standby GmbH quickly realised that the small gears had to be customised. At first, the injection-moulding process was an option. However, it was considered inefficient due to the relatively small number of parts required.Solution

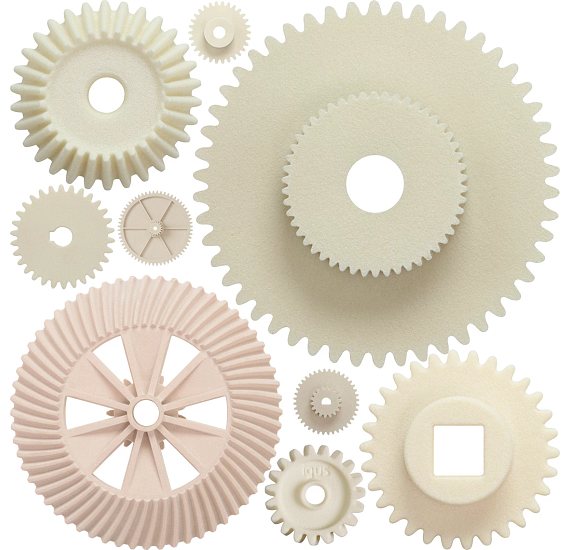

With a dimensional accuracy of ±0.1mm, the gears were produced in series from iglidur i3 powder with an additive method - the SLS process. Furthermore, the material iglidur i3 enables maintenance-free operation of the searchlights thanks to its high wear resistance and self-lubricating specifications. Thus, the igus 3D printing service met all of Standby GmbH's requirements.To what extent are the 3D-printed plastic gears particularly wear-resistant?

Standby GmbH itself tested the durability of the 3D-printed gears by first subjecting some printed test samples to their own wear test. Mr. Klaus Pfiffer, Technical Support at Standby GmbH, says: "The result was outstanding. Even after many cycles and operating hours, which were far above what was previously specified for maximum product service life, the printed gears and pinions showed no wear, not even those whose partners were not made of iglidur but aluminium."To the gear service life calculator

Selective laser sintering (SLS): precise solutions with a long service life

In many sliding applications, small components offer mechanical or aesthetic benefits. A creative, detailed design of a product requires a manufacturing method that accurately and cost-effectively meets the design requirements. The additive manufacturing of components based on the aligned melting of powder layers characterises the SLS process, which is suitable for the production of tailor-made special parts. For this purpose, igus uses tribologically optimised plastic powders with self-lubricating specifications. The resulting wear-resistant parts can be gears, worm gears or plain bearings, for example.

igus has developed suitable high-quality 3D printing materials for the various mechanical applications. iglidur i3 is most often processed in the printing service and is characterised by high stability and abrasion resistance, which is ideal for all types of gear shapes. If machine parts can be moved with a worm wheel system, iglidur i6 is recommended due to its increased sliding ability. In addition, some application environments require specific material specifications, such as food conformity. igus has also developed 3D printing materials for these and other requirements.

igus has developed suitable high-quality 3D printing materials for the various mechanical applications. iglidur i3 is most often processed in the printing service and is characterised by high stability and abrasion resistance, which is ideal for all types of gear shapes. If machine parts can be moved with a worm wheel system, iglidur i6 is recommended due to its increased sliding ability. In addition, some application environments require specific material specifications, such as food conformity. igus has also developed 3D printing materials for these and other requirements.

Find the right SLS material now.

Further application examples with components printed in 3D

All customer applications at a glance