3D printing for fully automated coffee machines

- What was needed: Components for the mechanism of an automatic cup tray adjustment for a fully automatic coffee machine

- Manufacturing method: Selective laser sintering

- Requirements: Food conformity, strength, stability, good operation properties, dimensional accuracy

- Material: iglidur i6

- Industry: Vending machinery

- Success due to cooperation: high abrasion resistance, toughness and long service life

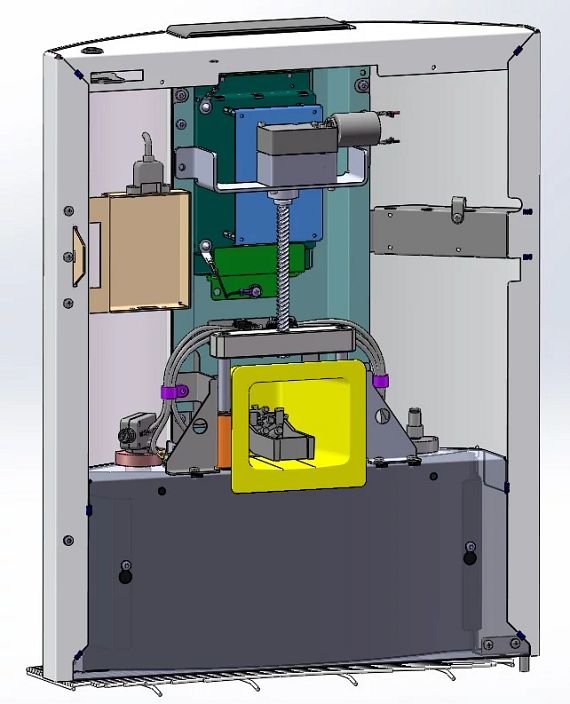

until now, the fully automated coffee machine cup tray has been adjusted to the cup size by hand. To fully automate tray adjustment, the project team from Maschinenbauschule Ansbach, a mechanical-engineering educational institution, developed a moveable, motor-driven cup tray with sensor-controlled height adjustment. The height adjustment mechanism used a motor, a 3D-printed shaft end support and a 3D-printed lead screw. The 3D-printed parts made of the high-performance plastic iglidur i6 have excellent operating properties, stability and service life.

Go to 3D printing service

Problem

Up to now, the height of the fully automated coffee machine's cup tray was adjusted to the cup size by hand, which is why an automatic solution was required. A team from the mechanical engineering school Ansbach developed a motorised mechanism for a sensor-driven height adjustment. The suitable materials for this concept "shaft end support - spindle" still had to be found. The concept had to have excellent operating specifications between shaft end support and spindle, and a reliable dimensional accuracy to adhere to the dimensions in the coffee machine's interior. At the same time, the materials had to be suitable for food contact and the entire weight of the cup(s).Solution

The project team found the perfect partner in Cologne-based igus GmbH. Working with the Head of Additive Manufacturing Tom Krause, the team first produced a mechanical concept prototype with 3D printing. They used iglidur i6 high-performance polymer, which igus had specifically developed for laser sintering. The team appreciated its high stability, dimensional accuracy and operating characteristics. After revising and improving the concept, the team ordered all components from the 3D printing service. Besides the specifications mentioned above, the mechanism featured high abrasion resistance and level of detail. The tool-free nature of the laser-sintering process and the efficient part production with no minimum order quantity were also helpful.How the automatic cup tray adjustment works

The term fully automatic coffee machine mainly refers to the fully automated process of coffee preparation. Up to now, the height of the cup tray has been adjusted by hand to accommodate the different cup sizes. To make sure the fully automated coffee machine is worthy of its name, a project team from the Ansbach mechanical engineering school, developed an automatic and useful cup tray adjustment. This uses sensors to determine the height adjustment, which then sets the motorised mechanism attached to the lever arms in motion, which consists of a 3D printed spindle and shaft end support. The sensors measure the travel between the upper rim of the cup and the bottom edge of the drink outlet, and recognise both transparent and opaque cups. By using software, the motor is then controlled until the defined distance is reached.

iglidur i6 - abrasion-resistant high-performance polymer

The tribologically optimised and very abrasion-resistant iglidur i6 plastic was used for the mechanism. The spindle-shaft end support operating characteristics were a decisive factor prompting the team to choose this material. The igus materials are very important, especially for vending machinery. Integrated solid lubricants make external lubrication unnecessary. This allows a hygienic operation, among other things. The material, which was specifically developed for laser sintering, has a much longer service life than conventional plastics.More about iglidur® I6

Material data sheet for iglidur i6 (PDF)

Other application examples for 3D printed components can be found here:

All customer applications at a glance