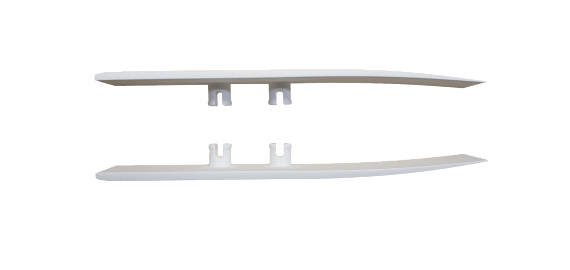

3D printing adapter clips for igus® energy chains

The developed adapter clips served as a ramp to relieve the glide pads and increase their service life. The igus® 3D printing service, which was able to produce the individual components quickly and easily, was called in to develop these adapter components. Using the prototypes, it was possible to test different product specifications quickly, leading to a shorter development time and lower costs compared to previously used manufacturing methods. The high-performance polymer iglidur® I6 was used with selective laser sintering. It is abrasion-resistant while showing good sliding properties, from which the energy chains benefit in harsh environmental conditions.

Would you like more information about the our 3D printing or do you need an individual consultation? Our experts will be happy to get in touch with you.

Would you like more information about the our 3D printing or do you need an individual consultation? Our experts will be happy to get in touch with you.

Contact an expert

Problem

To increase the service life of igus energy chains, glide pads were developed that were integrated into the module at a later stage. However, this construction resulted in a difference in height at the transition between glide bar and glide pads. To compensate for this height difference, an adapter clip was required. Since the chains are mostly used in abrasive environments, they should have a long service life, e.g. through high abrasion resistance and good sliding properties. Only a few parts should be manufactured for the development phase in order to be able to test product properties and functions without having to build expensive and complex injection moulding tools beforehand.Solution

Developing the individual adapter clip proved to be fast and cost-effective thanks to the igus® 3D printing service. Low volumes were produced within a short time to test and improve the different product specifications, and to have realistic samples at an early development stage. Furthermore, it was possible to monitor the functional behaviour without having to construct injection moulding tools in advance. The reduced development time also led to lower development costs. With the individual parts made of iglidur® I6, the adapters were able to fulfil all mechanical requirements that occur in harsh environments at the same time.Tool-free production - cost-effective, fast and resource-saving

One of the greatest benefits of additive manufacturing is the tool-free production. In contrast to conventional manufacturing procedures, such as milling or injection moulding, no additional tools are needed here. Therefore, it is possible to print low volumes, which is very useful in the development phase. At the same time, the manufacturing process produces no waste as the left-over laser sintering powder can be reused after printing. Apart from the low costs, the printing and the material can be adjusted and improved quickly, as was the case here. As only one left and one right adapter clip are necessary per chain, the entire quantity for one order remains low. Development is reduced and development costs remain low. The feel and appearance could also be evaluated within a very short time. The simple order process of 3D printing was also decisive for ordering the individual parts.

Good sliding properties with iglidur® I6

In the development phase, the material iglidur i6 was chosen, which had been specifically developed for laser sintering. The parts made of the high-performance polymer are very abrasion-resistant and have a longer service life than milled components. First tests of the chain confirm these specifications. As soon as the adapter clips had been "ground in" after the first friction, no further wear was detected. The integrated solid lubricants ensure good sliding properties and help the parts withstand the high friction in the transition between glide pad and glide bar. According to Product Manager Christoph Koch, the quality of adapter clips printed in 3D from iglidur i6 is comparable to that of parts made via injection moulding.For more inconspicuous components on the energy chain, it is possible to colour parts made of i6 black, if desired, or to manufacture the adapters from the black SLS powder iglidur i8-ESD.

Find out more about iglidur® I6

Other application examples for 3D printed components can be found here:

All customer applications at a glance