Precision and good sliding properties - with iglidur high-performance polymers for a precisely fitting fixture for a profile saw

- What was needed: Device for a profile saw

- Manufacturing process: Filament extrusion (FDM) & selective laser sintering (SLS)

- Requirements: Accuracy of fit, good sliding properties, abrasion resistance

- Material: iglidur® i190 & iglidur® i3

- Industry: Machine tools

- Success through cooperation: More accurate sawing of the rails possible

The application at a glance:

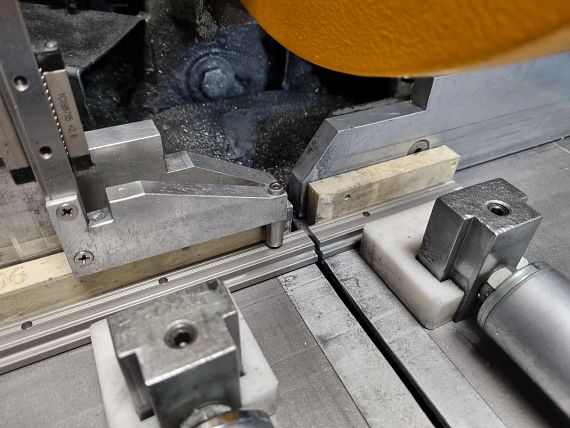

To ensure that the cutting of igus drylin rails always has exactly the same distance to the first or last hole, the drylin engineers have designed a device that holds the rails at right angles to the working surface of the profile saw. Without this device, they would rest at an angle on the work surface, making it difficult to cut the rails with repeatable accuracy. With a first device made of aluminium quickly appeared scratches on the rails. For a test phase to find a suitable material, two devices of different lengths were made of iglidur i190 and iglidur I3. Initial tests speak for themselves: Due to the tribological properties of the iglidur materials, scratches no longer occur on the rails and almost identical cutting to size is now possible.

More about the igus 3D-printing service

Problem

With a profile saw, which is used among other things for large orders, linear rails from the igus drylin® range are cut to size according to customer requirements. When clamping the rail, a pin is inserted into the first hole so that the distance between the hole and the end of the rail can be defined. This is important to ensure a precise fit of the rail in the customer application. However, this was not always exact until now, because the rail was resting at an angle on the work surface and so the conical pin could not be inserted into the hole at the correct angle. So a precision-fit jig was needed to hold the rail at right angles to the profile saw and thus guarantee correct engagement of the pin in the hole. In addition, the material of the device should have good sliding properties, so as not to cause damage, such as scratches, on the rails. Furthermore, a high wear resistance of the device was important, as it is exposed to high stress in daily use.Solution

A first device made of aluminium caused scratches on the rails. An alternative solution was quickly found in the 3D printing service from igus. Within a very short time, a long and a short fixture for the saw cell were constructed. The larger part could be manufactured quickly in the filament extrusion process from iglidur i190 , whereas the smaller part could be planned and printed more easily in selective laser sintering from iglidur I3. Both tribologically optimised materials were able to meet the requirements. There are no more scratches on the rails and the accuracy of fit provides better stability and increased accuracy when sawing.Geometrical freedom with 3D printing - configure individual components yourself

In contrast to conventional manufacturing processes, such as milling or eroding, in which material is removed, the principle of additive manufacturing - as the name already suggests - consists of the layer-by-layer addition of material. This process is therefore particularly well suited for complex geometries, and also for customised components that do not conform to standard dimensions. Although individualised measurements are possible in principle with conventional processes, they are associated with high prices. In 3D printing, these parts or alterations can be implemented without any problems. Here a milled fixture would have cost at least €100, the individual component made of iglidur I3 costs €85. The igus online CAD configurator is ideal for configuring individual components. Here, prefabricated CAD models can be configured free of charge according to requirements and, after just a few clicks, it is possible to check whether the component can be implemented in the 3D printing service.Go to CAD configurator

iglidur I190 & iglidur I3 - tribologically optimised materials

With more than ten different materials and for various additive manufacturing processes, igus offers a wide selection for all possible applications. Especially in the test phase, this can become an advantage: the fast and cost-effective production of prototypes help in deciding which material is best suited for the application. Because each material has different advantages for different customer applications. In this case, two components of different lengths were manufactured: the long insert was created in the filament extrusion process (FDM) from iglidur I190 because it could be produced faster on the FDM printer. The short stop-dog was manufactured in the laser sintering system made of iglidur I3 as it can be dimensioned easily. All iglidur materials are tribologically optimised materials - so-called high-performance polymers. They are enriched with solid lubricants and thus do not require external lubrication. The iglidur i190 printing filament has a high wear resistance and excellent mechanical specifications (strength, toughness, layer adhesion). It can be processed on standard 3D printers and the abrasion resistance is better than ABS by up to 50 times. iglidur I3 is laser sintering powder and, like iglidur i190 , has a high wear resistance and extreme strength. The iglidur I3 is particularly suitable for applications where high detail accuracy is required, e.g. for any kind of gears.Go to 3D printing material shop

Collaboration with Ultimaker - processing of wear-resistant materials made easy

Since the end of 2019, there has been a material partnership between the leading and globally renowned manufacturer of 3D printers in the prosumer sector Ultimaker and igus GmbH. Specifically, this means that in the Marketplace of the slicing software "Cura", which was specially developed for Ultimaker 3D printers, optimised profiles for the tribofilaments are available from igus (including the new iglidur i190 filament). The big advantage is that the material properties for printing are directly taken into account by the product range, thus eliminating the need for an initial test phase for the interaction of 3D printer and filament. Material, but also time and costs can thus be saved with every printing process. This means that Ultimaker customers can print out small and large wear parts themselves and benefit from this unique cooperation.To the material profiles in the Cura Marketplace

Further application examples with components printed in 3D

All customer applications at a glance