Wear-resistant, hygienic, precise - quickly printed components for Corona test

Wear-resistant, hygienic and precise – quickly printed parts for providing relief in Corona testing

An automated drive-in Corona testing station, BoKa Automatisierung GmbH, a service company, needed a gripper for its robot arm that would deliver test tubes with precision to test subjects. The gripper would have to be operated non-stop so as to enable as many automated tests as possible. The speed of laser sintering and the delivery within a single day to the Cologne location were the crucial criteria that prompted BoKa to choose igus® GmbH as a collaboration partner. In addition to great abrasion resistance, the components, which igus® laser sintered, were impressive because of the solid lubricants contained in the high-performance polymer, which help meet the hygienic requirements of such a testing station.- What was needed: gripper for a robot arm

- Manufacturing method: selective laser sintering with laser sintering powder

- Requirements: good sliding properties, wear-resistant, consistent precision

- Material: iglidur® I3

- Industry: medical sector, robotics

Contact an expert

Quickly delivered components from the 3D printer for robot gripper arm in a Corona test station

Problem

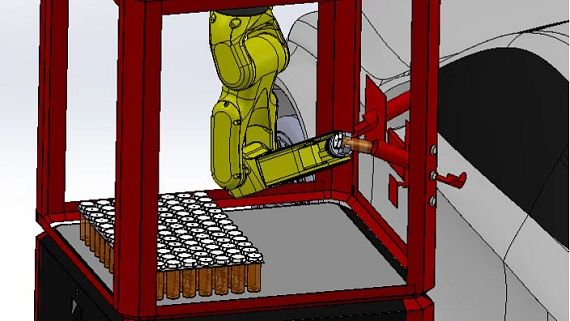

During the course of the Corona pandemic, tests have become normal when an infection is suspected. BoKa Automatisierung GmbH, a young industrial service company based in Dorfprozelten, Germany, has developed a drive-in Corona testing station ("DriCoMaTe") to relieve medical personnel and protect them from infection. The six-axis robot arm, which distributes test tubes to test subjects and retrieves them again, required a gripper that would ensure smooth operation for a long time.Solution

Thanks to the comparatively high speed at which components are manufactured using the SLS process, igus® was able to present a prototype for the robot gripper in a very short time. iglidur® I3, a high-performance polymer, proved to be a suitable material for the gripper. Being wear-resistant this ensured a long service life despite heavy usage. iglidur® I3 is also attractive because of its self-lubricating properties, which mean a better hygienic standard for the test station.Drive-in Corona testing functionality

The test subjects drive to the testing station. There, they are guided step-by-step through the sampling process with video instructions. The personnel ID is scanned, and disinfectant for the test subject's hands is provided. The station then associates the test subject's personal data with a test tube by means of a barcode. This is where the six-axis robot arm with its gripper comes in: it hands over the tube so that the user can deliver the sample. A medical professional can monitor the sampling by camera to ensure that the sample is usable. After the sample has been successfully deposited in the tube, the user returns the tube to the gripper, which places it in storage until it can be transported to the laboratory. This no-contact automation both relieves medical personnel and protects them from infection. BoKa says that the sampling procedure takes about four to six minutes. The testing system can serve two people at the same time, collecting around 500 samples in 24 hours.Quick, cost-effective manufacture during the pandemic

During the current global pandemic, it was especially important to manufacture and deliver the gripper quickly so that the test station could be introduced to medical facilities and government agencies. The speed of laser sintering and delivery within a single day to the Cologne location were the crucial criteria that prompted BoKa to choose igus® GmbH as a collaboration partner. At the same time, the cost-effective manufacture of the customised gripper was impressive. Unlike machined parts, 3D printed robot grippers do not require tools, which means no set-up costs.

iglidur® I3 as a reliable component in the robot gripper

Given around 500 test subjects in 24 hours, the robot gripper is subjected to constant load and movement. iglidur® I3, a wear-resistant 3D printing plastic, allows these movements to be performed easily while retaining gripper precision over time. The material was developed specifically for manufacturing friction-sensitive parts, and its abrasion resistance is up to 50 times that of other plastics. The SLS process can be used to precisely adapt and manufacture the high-performance polymer to customer requirements. At the same time, the material exhibits great stability in use. The solid lubricant embedded in the plastic allows operation without external lubrication, contributing to an improved testing station hygiene standard.

Find out more about iglidur® I3

Other application examples for 3D printed components can be found here:

All customer applications at a glance