Due to their improved tolerances, 3D-printed gears make objects in shop windows float

- What was needed: gears with exact tolerances

- Manufacturing method: selective laser sintering (SLS)

- Requirements: freedom from maintenance, low noise, smooth running

- Material: iglidur I3

- Industry: furniture design

- Success through cooperation: maintenance-free components, vibration-free and low-noise rotation of the objects, the illusion can be maintained

The application at a glance:

The Belgian company Levita has made it its business to present high-quality products such as wristwatches, mobile phones, glasses or jewellery in a special way. For this purpose, it has designed a display case that makes medium-sized objects "float" by means of two linear movements and a rotation, while at the same time turning them 360° around their own axis. However, for the linear movements and vibration-free rotation of the mechanism, glide-optimised components were needed to create the illusion of floating objects.

The Belgian company Levita has made it its business to present high-quality products such as wristwatches, mobile phones, glasses or jewellery in a special way. For this purpose, it has designed a display case that makes medium-sized objects "float" by means of two linear movements and a rotation, while at the same time turning them 360° around their own axis. However, for the linear movements and vibration-free rotation of the mechanism, glide-optimised components were needed to create the illusion of floating objects.

Problem

For this unique way of product presentation, the company needed a reliable mechanism. One of the biggest problems was to sidestep the stick-slip effect. Further requirements the mechanism had to fulfil were maintenance-free components and a low-noise operation. The 3D-printed gears used initially did not have sufficient tolerances and therefore caused strong vibrations.Solution

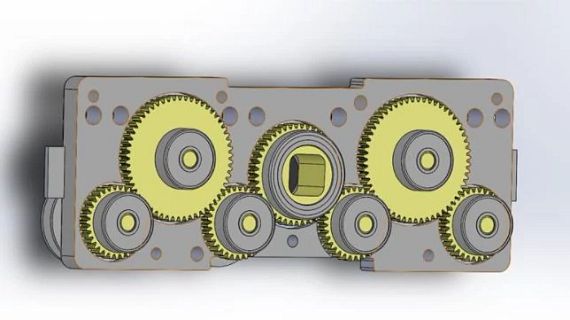

With various products from igus, it was possible to design and produce a smooth mechanism for the showcase that is both quiet and works without the initial vibrations. The stick-slip effect could also be eliminated. For the rotation system, Levita used the iglidur® PRT-01 slewing ring and 3D-printed gears made of the tribologically optimised iglidur I3 plastic. Thanks to the improved tolerances (0.1mm instead of 0.2mm) and the accuracy of SLS printing, vibrations have been drastically reduced. This preserves the optical trick of the slowly floating object. In addition to the good mechanical effects of the igus components, the integrated solid lubricants in the plastic parts come into effect, as they enable a maintenance-free operation without stick-slip effects.Selective laser sintering at igus - implementation of filigree components

Apart from the strand deposition process (FDM), the igus 3D printing service offers selective laser sintering as a manufacturing process for additively manufactured components. In the SLS process, a laser selectively heats spots in a powder bed that fuse together to form a previously constructed, three-dimensional object. A doctor blade redistributes the powder after each melted layer. This process doesn't require tools, which is reflected in both the price and the speed of production. Components manufactured via the SLS process show very precise dimensional accuracy as well as high strength and good layer bonding. For "The Box" by Levita, the attention to detail in the printing was particularly important - without it, the change in tolerance from 0.2mm to 0.1mm would not have been possible.iglidur I3, iglidur I6, iglidur I8-ESD - 3D printing of all types of plastic gears at igus

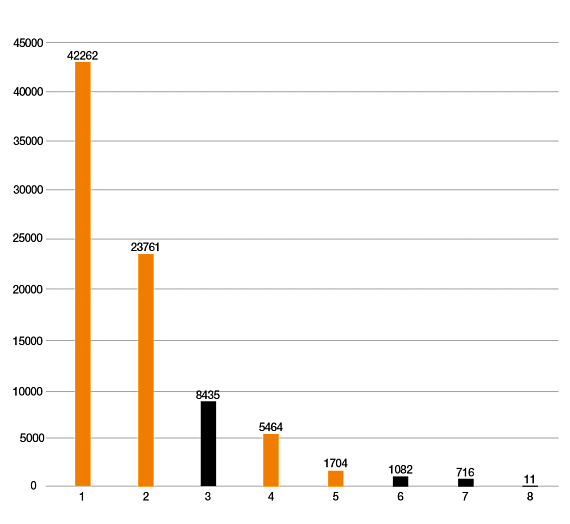

SLS materials made from high-performance polymers provide up to five times longer gear service life than milled gears made from regular plastics. Thanks to the igus test laboratory, these values can be confirmed again and again through realistic tests. Different application areas for the materials iglidur I3, iglidur I6 and iglidur I8-ESD have also emerged based on the test results. That way, iglidur I3 is particularly suitable for spur and bevel gears, as it has a higher strength. The detailed processing and exact surfaces are also in favour of an application with all other gear shapes. In addition to iglidur I3, iglidur I6 also impresses with its optimised gliding properties and is especially recommended for worm gears as well as for applications in which food-compliant components are indispensable. iglidur I8-ESD ideal when gears with ESD specifications are required. These are used, for example, in ATEX machines. In addition to the different application areas, the test results from the igus laboratory provide the basis for an online service life calculator for gears. Based on the empirically collected data, customers can easily determine the exact service life online using their specific parameters for their gear application.Go to service life calculator

Further igus products in this application example:

Further application examples with components printed in 3D

All customer applications at a glance