Cosmetic Manufacturing with motion plastics

Reliable components for a continuous and automated production line.

The reliance of a continuous production line during cosmetic manufacturing means downtime should not be a concern. Therefore, careful selection of the right products is vital during cosmetic manufacturing. igus® components ensure a risk-free, agile manufacturing process thanks to our maintenance and lubrication-free qualities.With industry 4.0, igus® condition monitoring products will eliminate the fear of unexpected downtime of your machines. Using an isense® energy chain in your production line will detect any fault in the chain, allowing you time to amend the problem and avoid any pause in production.

Would you like more information about the range of products suitable for cosmetic manufacturing? Our experts will be happy to get in touch with you.

Contact the expert

Products suitable for cosmetic manufacturing

Delta robot

- For loads up to 5.0[kg]

- For precision requirements up to approx. 0.5mm

- Suitable for pick and place applications

Find out more

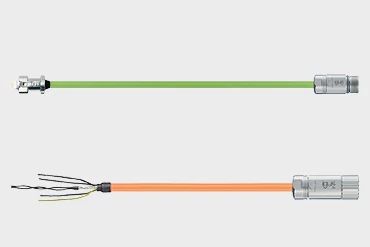

e-skin® flat

- Modular and compact design

- Replace cables quickly

- Suitable for cleanrooms according to IPA ISO

Find out more

.jpg?crop=no&color=ffffff00&w=370&quality=80)

xiros® guide rollers

- Lubrication-free

- FDA-compliant components available

- Length of the roller: 50mm-500mm available

Find out more

SLW linear modules

- Low-profile linear rails or robust high profiles

- Variable carriage widths and lengths

- Availability to configure a custom system online

Find out more

We can protect your products

FDA and EU compliant

Products manufactured in the cosmetics industry involve direct contact with the human body, such as skin and hair care products. Therefore it is vital that the manufacturing process complies with the highest hygiene grade under the EU-10/2011 standards.igus® provides a vast range of FDA compliant products suitable for cosmetic manufacturing, including energy chains, plain bearings and tribo coating.

Find out more

Similar industry application examples

Printed in 3D: maintenance-free gripper for the packaging industry

Fast availability at a low price and use under hygienic conditions were important prerequisites for this 3D-printed gripper. It is used to package cosmetic products and has the special advantage of working without additional lubrication, hence fulfilling hygienic requirements.

More flexibility through 3D printing

Fully automatic labellers

Today, reliable and efficient machines are required for the labelling of products. What matters is a combination of speed, precision and flexibility. A failure of the labeller? That would be annoying and on top of that very costly. Bluhm Systeme GmbH therefore not only develops fully automated marking systems with labels, inkjet or laser, it also relies on durable and maintenance-free drylin® linear bearing technology.

Bluhm Systeme GmbH

Bluhm Systeme GmbH

More information about this application

drylin® TR high helix thread nuts for laboratory equipment

drylin® TR high helix thread nuts were used in laboratory equipment for handling fluids. The advantage for the cleanroom is their low coefficient of friction. This leads to higher efficiency.

Furthermore, no lubrication is necessary, which prevents contamination.

Furthermore, no lubrication is necessary, which prevents contamination.

More information about this application

Sleevematic TS labelling system

Successful cooperation for more than 25 years

A wide range of igus products are used in the Sleevematic TS. From lubrication-free drylin polymer nuts in the belt station and sleeve brush, and drylin profile guides in the inlet and outlet sensor, up to drylin SLW lead screw lift tables in the preliminary shrinkage process and for height-adjustment of the guide rollers.

Krones AG

Krones AG

More information about this application

Frequently asked questions about cosmetic manufacturing

What equipment is needed for cosmetic manufacturing?Some of the main equipment used for cosmetic manufacturing include mixers and filling equipment. Many igus® products can be found within these types of equipment including plain bearings, linear guides, guide rings and energy chains.

Are your products suitable to use in conditions that require the highest hygeine standards?

Yes, igus® provides a vast range of FDA and EU-10/2011 compliant products suitable for cosmetic manufacturing. Find out more here- https://www.igus.co.uk/info/fda-eu-compliant

I want to automate a cosmetic's production line, what igus® product is best suited for pick-and-place applications?

The drylin® delta robot's primary purpose is picking and placing objects, where it can perform up to 60 picks per minute. This can be increased by using more sophisticated PLCs to control the interpolation of the 3 x dryve D1 motor controllers.

Read more FAQ's here

%20(1)%20cropped.jpg?h=425&crop=no&w=570&quality=80)