Filling systems

Overview

Filling systems or filling stations often constitute modular individual sections of a larger packaging line. Regardless of whether it is a partially or fully automated system, our modular rotary and linear bearing technology can be installed in any beverage filling system. At the centre of the filling station is the filling arm, which precisely fills containers such as pails, canisters or hobbocks with different contents and in a wide variety of sectors.The top priority of these components is that they are easy to clean, do not require lubricants and fulfil high service life requirements.

Would you like more information about igus® products within filling systems or require an individual consultation? Our experts will be happy to get in touch with you.

Contact an expert

Areas where igus® products are used in filling systems

Control valve

iglidur® J plain bearings or iglidur® H370 guide rings are used for control valve linear movement in the filling system.

Filling and dosing station

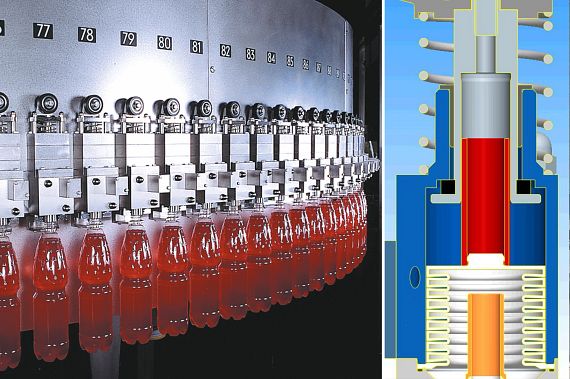

The bottles are lifted by at the valves and pumps of the filling stations by drylin® T-rail guides. In the cam-guided lifting element for the bottles, plain bearings made of iglidur® J, drylin® JUM liners or iglidur® H plain bearings are also used.

Operating mechanism for a circular filler

The pivoting movement in the pinion bearing uses iglidur® J guide rings that are more wear-resistant than PTFE strips and have a high load capacity. A drylin® R JUM linear bearing is used for cam-guided linear movement.

Clamping wheel

iglidur® J or iglidur® X plain bearings are used as bearings for the clamping elements. Two-component rollers made of an iglidur® plastic roller and a TPU outer jacket ensure the smooth and wear-free movement on the rotary axis.Product application examples

The following filling systems provide some important examples of applications for igus® products, including our linear bearing and plain bearing technology.They are used in various parts of the system.

For example, in the clamping wheel for holding the bottles or in the filling and dosing station.

Application examples of our customers

Beverage filling system

In the customised filling systems of Küppersbusch GmbH, plain bearings from the igus modular construction kit have been in use for more than twenty years.Find out more

Bottle aligner in filling system

iglidur plain bearings are wear-resistant, lubricant- and maintenance-free when used in beverage filling systems.Find out more

Sterile filling system

This pharmaceutical filling system relies on lubrication- and maintenance-free bearing technology.Find out more

Clamping star wheels in filling plants

Two-component plastic rollers for clamping star wheels double the service life of filling machines.Find out more