e-skin® corrugated tube for cleanrooms

Safe and abrasion-resistant guidance of cables in cleanrooms

To ensure cleanrooms remain free from particles, all machine parts - the energy supplies too - have to be abrasion-resistant. With the e-skin® corrugated tube systems can be supplied with data, media and energy without unwanted particles contaminating the air.The corrugated e-skin® tube is available in an enclosed version and a version with chambers that can be opened individually. This flexibility is an innovation and unique on the market so far. Furthermore, e-skin® has sufficient inherent rigidity and a defined bend radius (55 to 100mm).

The oval geometry ensures lateral stability. Short unsupported lengths are possible, even in small installation spaces. In addition, the energy supply is very quiet. Its noise level is only 29dB(A), 5dB(A) lower than that of conventional clean cables.

Would you like more information from our e-skin® expert or dicsuss your application?

Contact an expert

Product selection

The e-skin is a corrugated tube consisting of an upper and lower shell that form a complete enclosure when connected. The simple, resealable opening mechanism makes it easy to maintain and inspect cables the e-skin contains. The e-skin has many advantages over conventional corrugated tubes and is available in three different versions:e-skin® energy chain options

e-skin® SK

- For unsupported lengths up to 2M

- For installation space from 250mm

Find out more

e-skin® SK Soft

- For unsupported length up to 1.3M

- For installation space from 150mm

Find out more

e-skin® hybrid

- For unsupported length up to 1.4M

- For installation space from 200mm

e-skin® flat

- Closed and openable versions available.

- Very compact structure

e-skin® configurator

- Select the correct energy supply in cleanroom

- Select all your application perameters

Configure your e-skin®

Frequently asked questions

What is e-skin®?

The e-skin® energy chain range was developed especially for cleanroom applications, to ensure no contamination.

What applications would you use e-skin®?

Cleanroom environments is one of the main industry's, medical, pharmecutical and semiconductors.

Do you offer cables for the e-skin®?

Our Chainflex® CF10 is cleanroom compatible. For the e-skin® flat we have our CFCLEAN range.

Read more FAQ's

e-skin®: openable solutions for cleanrooms

Including semiconductor manufacturing

The e-skin® energy chain is predominately used in the manufacture of semiconductors. These applications are exceptionally sensitive to dust so require special cleanroom manufacturing conditions.igus® developed a modular corrugated tube and a flat cable guidance

system to ensure energy supply could be provided to work in such

specialised environments.

Continue reading

Real-world examples

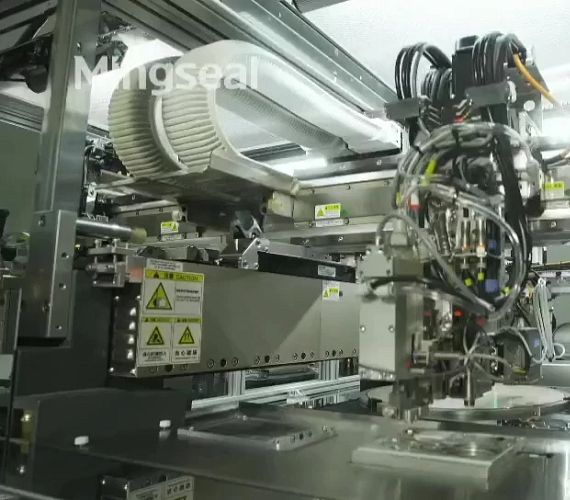

Adhesive dispenser for camera modules

Customer requirements: The company Mingseal manufactures products for the 3C industry (computer, communication and consumer electronics). The main product is an adhesive dispenser for camera modules. The igus E3 and E6 energy chain systems, which are already suitable for ISO class 1 according to IPA, were previously used as energy supply systems. Nowadays, however, the market demands an even higher particle-free standard (and thus theoretically an even better ISO class) than before, especially for mobile phone camera modules. The reason for this is the ever-increasing number of pixels on mobile phone cameras, because if there is just one particle on these modules, the entire module is abandoned and the overall equipment effectiveness (OEE) and the yield (YIELD) of the system drop enormously.

Our solutions: In the first step, the customer had to replace the energy chain with other products, e.g. welded cleanroom ribbon cables. The disadvantages of this solution soon became apparent: on the one hand, it was not possible to open the welded ribbon cables to add or replace cables, and on the other hand, the cables broke very quickly because they had to support themselves. After only half a year, the first defects appeared on these welded cables, which in turn led to the system coming to a standstill. The igus cleanroom energy supply system e-skin convinced the engineers at Mingseal. The unique openable corrugated tube for cleanrooms, which consists of an upper and lower shell, combined the engineers' openability, inherent rigidity, and compactness requirements with the highest cleanroom suitability according to ISO Class 1. The compact e-skin series SKS20 will be installed in new machines in the future.

Our solutions: In the first step, the customer had to replace the energy chain with other products, e.g. welded cleanroom ribbon cables. The disadvantages of this solution soon became apparent: on the one hand, it was not possible to open the welded ribbon cables to add or replace cables, and on the other hand, the cables broke very quickly because they had to support themselves. After only half a year, the first defects appeared on these welded cables, which in turn led to the system coming to a standstill. The igus cleanroom energy supply system e-skin convinced the engineers at Mingseal. The unique openable corrugated tube for cleanrooms, which consists of an upper and lower shell, combined the engineers' openability, inherent rigidity, and compactness requirements with the highest cleanroom suitability according to ISO Class 1. The compact e-skin series SKS20 will be installed in new machines in the future.

Why the e-skin® corrugated tube?

1. Cleanroom ISO class 1.Virtually no wear or abrasion

2. Two-piece corrugated tube.

Consisting of upper and lower shell

3. Circumferential mounting.

KMA mounting bracket, optionally with strain relief

4. Oval design

Prevents unintentional sideways movement

5. Fully enclosed.

Protection against dust and water ingress

6. Resealable opening mechanism.

Can be opened and closed like a zipper

7. Optional vertical separation.

Consisting of individual separators and full-width shelves

8. Minimisation of abrasion

With the new inner separation made of tribo-optimised iglidur material, the wear can be reduced by up to 80%.

Application examples

Adhesive dispenser for camera modules

The e-skin® corrugated tube convinced the engineers at Mingseal. The unique openable corrugated tube for cleanrooms, which consists of an upper and lower shell, united the engineers' requirements with regard to accessibility, inherent rigidity, compactness and, of course, the highest cleanroom suitability according to ISO Class 1. In future, the compact e-skin® series SKS20 will be installed in new machines.

Find out more

Application examples

PCB production

An abrasion-resistant e-skin® corrugated tube from igus is used in machines for the production of printed circuit boards and semiconductors. Airborne-dust is no longer a problem with the e-skin®

Find out more

Application examples

Lifting systems

The e-skin® corrugated tube is used in lifting systems in the pharmaceutical sector or in biotechnology. It is robust, modular and can be shortened as necessary.