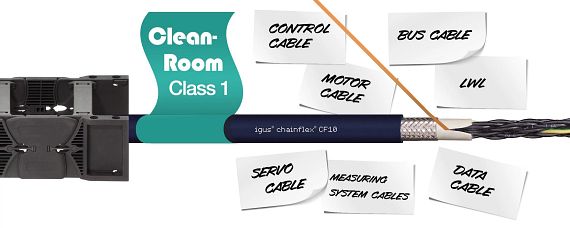

chainflex® cables in cleanroom

Great demands are placed on the cables used in the cleanroom. Moving components must be particularly abrasion-resistant because any contamination has a damaging effect on the product and the process. This costs money. For this, air currents within the room are defined that remove particles smaller than a hair. By using products with low abrasion, i.e. few particles, the cumbersome and expensive removal of particles is rendered unnecessary.

We develop and test our high-performance polymer products in our own cleanroom laboratory with the greatest care. To show that our products are ideal for use in cleanrooms, we have the Fraunhofer Institute subject them to further tests. This gives us an IPA-tested product portfolio with the best possible cleanroom classification (ISO Class 1).

What is cleanroom all about?

What is a cleanroom?

The cleanroom is a closed space in which the concentration of airborne particles is kept as low as possible. Cleanrooms are needed when then production of certain products needs to be protected from airborne particles. Typical areas include semiconductor manufacturing, medical technology, optics and laser technology, and aerospace technology, among others. The products of these industries could be contaminated by the smallest particles and thus become unusable. The cleanroom ensures trouble-free production here.How does cleanroom work?

In order to keep a room free of particles or germs, some measures have to be taken and the quality of the air as well as temperature and humidity have to be checked continuously. The cleanroom must only be entered wearing appropriate protective clothing after passing through an airlock. In the room itself, air streams and filters provide clean air.

What are specifications for materials and machines used in cleanroom?

In the cleanroom, high demands are placed on the material and machines used. Two points are particularly significant: 1. The air stream in the room must not be disturbed or only be slightly disturbed by the equipment in use. 2. The surfaces of all components used must have high abrasion resistance.chainflex® cables

Pneumatic hoses and various cables with IPA ISO Classes 1 and 2 are also available ready for connection, suitable for Bosch Rexroth, Festo, Parker, Siemens and many other manufacturers.

* Various igus® chainflex® cable families have been certified according to DIN EN ISO 14644-1 ISO Class 1 or Class 2 by the IPA Fraunhofer Institute (Reports IG1303-640-1 and IG0704-400). This corresponds to 1,084 different chainflex® catalogue cables with tested outer jacket material, 918 types with IPA Class 1 and 166 types with IPA Class 2.

igus products in cleanrooms

chainflex® CFCLEAN

- No bending of the system due to cables with stiff jacket cables

- Low restoring forces due to highly flexible stranded structure, special conductors and no outer jacket

- chainflex® CFCLEAN cables adapted to the application with up to 21% weight reduction compared to conventional cables

- Approx. 16% smaller diameter compared to standard cables with jacket

- Available from 1m

- Conductor prototypes: finished in 48-72 hours

- All standard core/cross section combinations: data, bus, control, motor - available from stock, with a guarantee of up to 4 years*

e-skin® flat

e-skin® flat and CFCLEAN - together they revolutionise your overall plant effectiveness, generate higher production line yields, and they are modular and conserve resources.The main advantage of the e-skin® flat is its modularity and easy maintenance. In contrast to commercially available solutions with firmly defined flat ribbon cables with welded stranded elements, the e-skin® flat energy chain system offers openable chamber systems. Flexible chainflex® CFCLEAN stranded elements (with or without connectors), support chains, hoses, etc., can now be replaced or added in just a few minutes.

- Highly efficient in the prototype phase

- Maximum availability through simple replacement of defective elements

- Saving resources, as only individual elements are replaced in case of damage

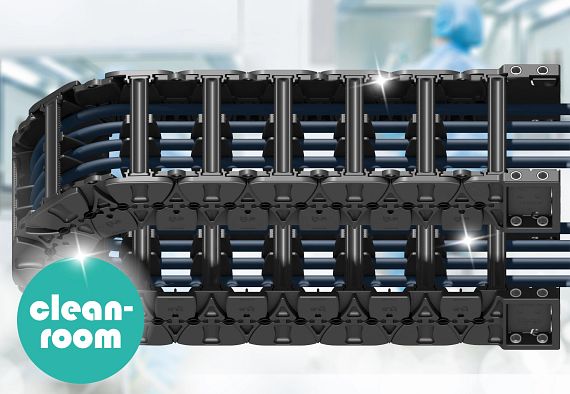

Energy chain series E6.1

With the E6.1, a new generation enters the cleanroom. The considerably simplified handling and improved accessibility to the interior and the reduced weight make assembly much easier. Our E6.1 naturally has our highly flexible cables in its luggage, which, with their abrasion-resistant outer jacket, are ideal for cleanroom applications.

- Extremely quiet due to the small pitch and "brake" in the stop-dog system

- (E61.29.070.055.0 at 1m/s = 32dB(A) according to igus internal test 4479)

- Extremly low vibration

- Low-abrasion connector system (no bolts and holes necessary)

- Virtually no polygon effect, thereby "smooth rolling" operation

- Smooth interior design for a long lifetime for cables and hoses

- E61.29 series: cross bars on both sides can be snapped open and removed along the inner and outer radii

- Weight savings approx. 30% compared to the System E6