Cleanroom solutions up to ISO Class 1

Would you like more information about our range of cleanroom solutions? Our experts will be happy to get in touch with you.

Cleanroom solutions | compatible products

Energy chains

Cables and hoses

Linear guides

Slewing ring bearings

e-skin® cleanroom energy chain

Configurator

Are you unsure which energy supply is the right one for your application? You can find the suitable solution with just a few clicks.

Energy supply for the cleanroom

In this white paper, you will learn how the right energy guidance in the cleanroom

- can increase plant effectiveness

- Generate higher yields of the production lines

- Use energy supply systems more sustainably

World premiere ...

... predictive maintenance in cleanroom with i.Cee EC.S

In this cleanroom highlight, the smart ultrasonic sensor technology is used to continuously monitor the current sag of the e-skin® flat with support chain. The e-skin® flat with support chain SKF.S is equipped with a defined bend radius and therefore enables unsupported lengths in cleanrooms. As soon as a critical condition of the energy supply system can be detected, predictive maintenance recommendations are issued.

Simple and safe cleaning:

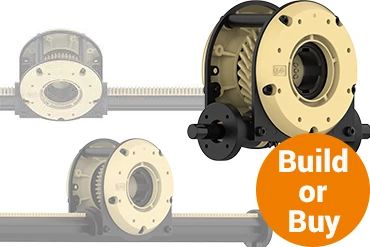

study on drygear® Apiro in hygienic design

- Simple, safe cleaning of cost-efficient iglidur® polymer gearboxes thanks to their open design

- Modular design for manual and motor-operated

- adjustments

- Fast conversion possible

- Assembly without any special tools

- Great product compatibility

Successful in use in cleanroom applications

Positioning systems in electronics manufacturing

This positioning unit uses a readychain system to reliably guide drive, measuring system, and compressed air lines – 24 hours a day, seven days a week.

Clean energy supply in adhesive dispenser for camera modules

Mingseal uses our e-skin corrugated tube in its adhesive dispenser for camera modules. It combines the engineers' requirements regarding openability, inherent rigidity and compactness combined with the highest cleanroom suitability according to ISO Class 1.

Filling system in laboratory technology

A clean bottling, which does not have to be sterile, but has to be very clean, and a low overall weight of the system

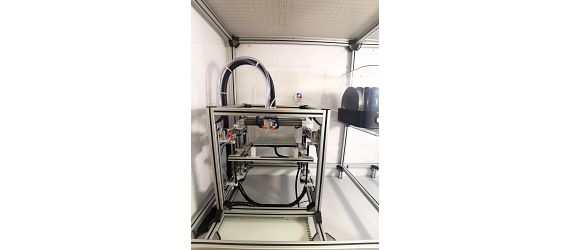

Cleanroom 3D printer

Precise, reliable cleanroom 3D printer for processing thermoplastics.

Linear system with air bearings for highly precise adjustments

An e-skin® flat SKF12.4.03.01.1 as a 4-fold layer together with PVC & TPE cables from igus® ensures the reliable energy supply of an air bearing linear system.

Energy supply systems in semiconductor manufacturing

Therefore, an abrasion-resistant energy supply is used, which is suitable for cleanrooms of ISO Class 3 (according to DIN EN ISO 146441-1).

Wafer handling

With E6 e-chain®, the supply of energy for wafer handling in chip production involving acceleration rates of up to 4m/s2 and speeds of up to 6m/s is not a problem.

drylin TR high helix thread nuts for laboratory equipment

Furthermore, no lubrication is necessary, which prevents contamination.

Further information

Cleanroom brochure

Cleanroom classes of our products and information on RoHs and ESD.Information about ESD

More about the igus material igumid for ESD applications.Frequently asked questions about cleanroom solutions

Do the igus® cleanroom solutions meet the increasing demands?

As the quality requirements for cleanroom technology applications are constantly growing, igus® is continuously working on improving its products. For this purpose, igus® has been carrying out tests for cleanroom suitability in its own test laboratory since 1997. In addition, appropriate products are tested externally by the Fraunhofer Institute.

Are igus® bearings suitable for cleanrooms?

The cleanroom suitability of our iglidur® plain bearings is determined on the basis of the wear particles released in the application. The size and quantity of the released wear particles depend on:

• the respective pairing of shaft and bearing material

• further parameters such as load, speed etc.

Therefore, there are no clearly defined cleanroom materials for our plain bearings, but instead they depend on their use.