"Pure" world premiere: predictive maintenance recommendations in the cleanroom

i.Cee EC.S - the new ultrasonic sensor on the e-skin® flat allows real-time condition-based information and maintenance recommendations for the best overall equipment effectiveness in the cleanroom.

The connected i.Cee module also allows numerous interfaces to comprehensive monitoring/IoT networks to make the cleanroom status information available to the user/system manager in real time. All information is aggregated in a modern dashboard, online or offline in the local network, depending on the customer's requirements.

Tech up

- Maximum e-skin® service life extension

- Increased cleanroom overall equipment effectiveness (OEE)

- Easy integration into the overarching machine network/IoT environment

Cost down

- Maintenance cost reduction thanks to predictive maintenance recommendations

- Avoidance of unplanned downtime thanks to condition-based alarm messages

- No unnecessary storage costs for expensive cleanroom materials

Proof

- Tested in the igus cleanroom laboratory and suitable for cleanrooms up to Air Purity Class 1 according to ISO 14644-1

- Over 100 successful i.Cee predictive maintenance projects in the field.

Sustainability

- Use cleanroom components to their latest possible end of life without premature replacement

- Avoid resource-intensive emergency operations

Predictive maintenance implemented successfully

Industry 4.0: i.Cee in practice

Wastewater treatment plants and wastewater operations |

Port and container cranes |

Conveyor and bulk handling

Avoid downtimes, extend service life

Avoid downtimes, extend service life

Société Nationale des Chemins de Fer Luxembourgeois (CFL)

Customer applications worldwide

Customer applications worldwide

To the application overview

Products by cleanroom class

| ISO 14644-1 | FED STD 209E | GMP (non-operational) | Max. particles (0.5 micron) m³ | Max. particles (0.5 micron) f³ | igus products that meet the standard |

|---|---|---|---|---|---|

| 1 | N/A | N/A | Energy chains, cables, corrugated tubes, pneumatic hoses | ||

| 2 | N/A | N/A | see above | ||

| 3 | 1 | 35 | see above + linear guides | ||

| 4 | 10 | 352 | see above | ||

| 5 | 100 | A & B | 3,520 | 100 | see above |

| 6 | 1,000 | 35,200 | 997 | see above | |

| 7 | 10,000 | C | 352,000 | 9,967 | see above |

| 8 | 100,000 | D | 3,520,000 | 99,675 | see above |

| 9 | N/A | 35,200,000 | 996,747 | see above |

The data for GMP and FED STD 209E only serve as a rough comparison and do not take other factors such as bacterial contamination into account. Please contact us to find the right configuration for your project.

energy chains

Cables and hoses

linear guides

Slewing ring bearings

Energy supply for the cleanroom

This white paper shows how the right energy guidance in the cleanroom can

- increase plant effectiveness

- generate higher yields from the production lines

- use energy supply systems more sustainably

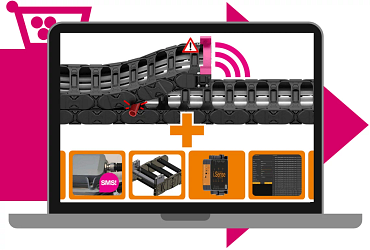

Smart machine data acquisition forms the basis for predictive maintenance concepts

Since the i.Sense Wonderbox is part of the smart plastics i.Sense condition monitoring system, all of its data can also be evaluated in the i.Cee control cabinet module. These data can then be used to digitally control the system's alarm and escalation management.

The i.Cee module can be integrated into predictive maintenance concepts in a number of ways, from preventive service management, which schedules regular maintenance depending on use, to location-independent fault management, which immediately reports any unforeseen change via various mobile channels. All information is collated in a modern dashboard, online or offline in the local network, depending on the customer's requirements.

White paper on optimising overall equipment effectiveness (OEE)

Clarifies the distinction between condition monitoring and predictive maintenance

This free white paper explains:

- What igus® condition monitoring (i.Sense) means

- What igus® predictive maintenance (i.Cee) means

- What technology is behind both systems

- What the two systems offer industrial energy supply

... Try it ...