Plain bearings

They can withstand extreme temperatures, are suitable for a wide range of applications and industries and are available in a range of standard catalogue options.

By switching to igus® plain bearings, customers can increase their technology and reduce their costs. igus® products can be shipped within 24 hours, can be configured using the service-life calculators and have been extensively tested in the laboratory.

Would you like more information about iglidur® bearings?

iglidur® plain bearing options

Flange bearings

- Various materials available

- Large range of inner & outer dimensions

- No minimum order quantity

Sleeve bearings

- Various materials available

- Available in metric or imperial

- Low coefficients of friction

Thrust Washers

- High wear resistance

- Various material options available.

- With or without a locating hole

Custom bearings

- No minimum order quantity

- Injection moulded or CNC machined

- From a large range of iglidur® materials

3D Printing Service

- Custom 3D printed parts

- Design your own with the CAD system.

- Choose from a large range of materials.

Did you know we also have a range of ball bearings?

Not only do we offer plain bearings but we have a large range of ball bearings as part of our standard catalogue range.If you want to view the range of ball bearings click here

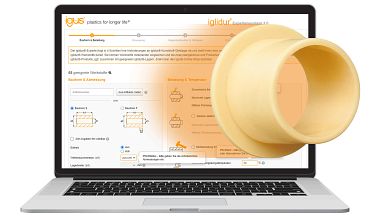

iglidur® plain bearing configurators

igus® plain bearings are manufactured from innovative high-performance plastics for a wide range of applications. We run extensive tests on the bearing materials to compile data into multiple online database. One tool within the database is the iglidur® Expert System. This system provides comprehensive suitability and service life analysis of all iglidur® materials allowing you to choose the best product for your application in a few easy steps.

Simply enter your requirements, including design, load, speed, shaft material and housing and discover the most suitable material and the lifetime of the bearing within your application.

Discover all the bearing tools here.

The advantages of our plain bearings at a glance

Lubrication and maintenance-free

Due to the self-lubricating effect, iglidur® plastic bearings do not require any additional lubricants. How it works? Our iglidur® materials contain solid lubricants, millions of which are contained in the material. These lubricants are released in tiny amounts and thus lubricate the bearing point. Therefore there are no problems with insufficient lubrication and only minimal maintenance requirements.

Cost-effective

Our self-lubricating plain bearings reduce your maintenance costs and save additional expenses for lubricants - with no minimum order quantity up to high volume. Our plastic plain bushes are up to 89% more cost-effective than plain bearings made of steel or bronze.Example: €2.37/piece versus €0.25/piece

Composite bearing steel/PTFE, size 2020 against iglidur MSM-2023-20

(Price for a purchase quantity of 100 pieces)

Calculate the service life

With the help of our free online tool you can calculate the service life of our plastic plain bearings for your application.How it works?

Our products are thoroughly tested in the test laboratory and the wear results are documented in our database. This data is then integrated in our online tool for service life calculation.

Available from 24 hours

We ship worldwide from over 73 countries to keep delivery times as short as possible for you.The most comprehensive product range for you:

- 10,000 installation sizes from stock

- Special parts according to your specifications

- Shipping within 24hrs

- No minimum order

- No minimum quantity

Resistant to chemicals and media

Our range includes a variety of different slide bearing plastics, which are e. g. characterised by high chemical or temperature resistance. Daily cleaning with aggressive cleaning agents and high pressure are therefore not a problem, since plastic bearing bushes from igus do not require any additional lubricants that would otherwise be washed out during cleaning.

Suitable for high loads

Our plastic plain bearing bushes are used e. g., in construction and agricultural machinery. In both cases, very robust plain bearing materials are required that can withstand not only dirt but also high loads. For this purpose, we offer on the one hand self-lubricating plain bearings made from our iglidur materials and for exceptionally demanding cases igutex plain bearings, which are reinforced with high-strength fibre-glass fabric.Frequently asked questions

How are plain bearings lubricated?

Plain bearings can be lubricated with oils, grease or other lubricants. These can be costly, very messy and can cause issues in regards to maintenance time to keep the bearings in working order. One of the advantages about igus® bearings, as with all igus® products, is that they are lubrication-free. The range of plain bearings are manufactured in technical high-performance plastic which ensures the optimum running performances, longest and measurable service life and lowest friction values, all without the use of additional lubrication.

Where are plain bearings used?

Plain bearings are used everywhere! They are used in a large variety of applications and industries, many of which require a cost-effective solution whilst maintaining a long service life. igus® plain bearings offer both of these elements, along with being lubrication-free and maintenance free. All of these attributes combined ensures a clean, smooth running movement within machines and applications.

What are self-lubricating bearings?

Self-lubricating bearings are bearings that require no additional lubrication, no oil or grease. These self-lubricating bearings are composed of thermoplastics and fibre reinforcements which means they are with a self-impregnated with solid lubricants. This ensures that the bearings can run successfully without additional external lubrication. Without the need for environmentally damaging lubricants, this prevents downtime, saves money, and reduces the impact on the environment.

How are iglidur® plain bearings tested?

In more than 12,000 individuals tests a year on over 200 test rigs in the igus® test laboratory, all materials are thoroughly tested. The findings go into a unique knowledge database on the tribology of maintenance-free plastic plain bearings. This database enables us to select the ideal iglidur® plain bearing for our customers depending on the application and to calculate its anticipated service life.

.png?crop=no&color=ffffff00&w=1170)