Maintenance-free heavy-duty and fibre composite plain bearings

Self-lubricating heavy duty bearings

Composite bearings are a combination of different materials. Mineral materials are woven with fibres, combined with synthetic resins and other additives and then pressed together under high temperatures and pressure.

With our igutex® plain bearings, a robust fibreglass fabric serves as the outer shell, while an inner layer optimised for sliding properties reduces friction on the shaft.

The combination of these materials results in high-strength composite fibre plain bearings that have been developed for very high loads and primarily used in agricultural, construction and mining machinery. As our igutex® composite bearings contain solid lubricants, they do not require any maintenance or additional lubrication.

Would you like more information about our TX bearings? Our experts will be happy to get in touch with you.

With our igutex® plain bearings, a robust fibreglass fabric serves as the outer shell, while an inner layer optimised for sliding properties reduces friction on the shaft.

The combination of these materials results in high-strength composite fibre plain bearings that have been developed for very high loads and primarily used in agricultural, construction and mining machinery. As our igutex® composite bearings contain solid lubricants, they do not require any maintenance or additional lubrication.

Would you like more information about our TX bearings? Our experts will be happy to get in touch with you.

Contact an expert

What is special about igutex fibre composite plain bearings?

Where injection-moulded plain bearings cannot be used due to excessive mechanical loads, wound igutex® fibre composite plain bearings play to their strength. They consist of two layers:

1 Gliding layer

The gliding layer consists of a filament fabric with solid lubricants, which makes the composite plain bearings self-lubricating and maintenance-free with particularly low coefficients of friction.2 Base layer

The outer layer of igutex® slide bearings is made of particularly hard-wearing filament fabrics and serves to protect the tribologically optimised inner layer.Shop igutex® fibre composite bearings

igutex® TX1

- Robust all-round material

- Up to 200 MPa static and 140 MPa dynamic

- Wear resistant and dimensionally stable

- Good media resistance

- Lubricant and maintenance free

- Standard program from stock

Visit the shop

igutex® TX2

- Perfect for hard shafts

- Particularly low wear in heavy-duty areas

- Up to 3.5 times more wear-resistant than igutex® TX1

- Good coefficient of wear and therefore a long service life

Visit the shop

igutex® TX3

- For continuous operation at the highest loads

- Lowest wear rates under extreme dry running conditions

- No lubrication and maintenance

- Tested in the igus test laboratory up to 130 MPa and 0.01 m/s swiveling

Visit the shop

Why you benefit from igutex composite bearings and iglidur plain bearings

Save time and money

✅ No costs for lubricants✅ No failures due to insufficient lubrication

✅ Time and money saved on daily maintenance

No loss lubrication

✅ No release of lubricant into the environment✅ No loss lubrication for wear protection

✅ No centralised lubrication necessary

Developed for high loads

✅ Extremely robust and wear-resistant✅ Tested under real operating conditions

✅ Predictable service life thanks to test database

igutex® fibre composite plain bearings are used here

Reliable despite dirt and grime

More on the application

Lubrication costs saved

More on the application

20 tons load and salt water

More on the application

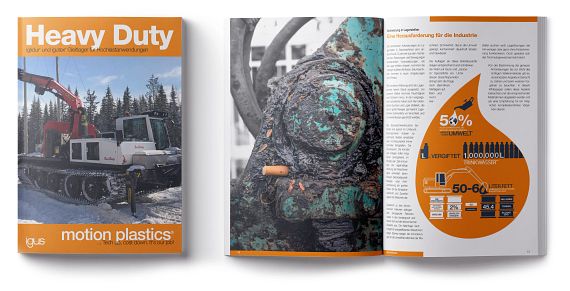

Free heavy-duty brochure

Find out more about the following topics:

- Discussions with our development experts

- Material overview with heavy-duty plain bearings

- How our plain bearing materials work

- Lubrication – a challenge for industry

- Sustainable product developments

- Test results of various plain bearing types

- practical application examples

Download now for free (PDF)

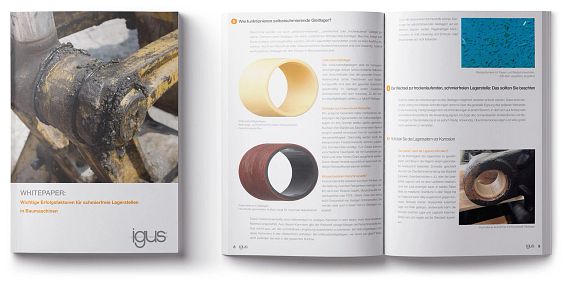

Free white paper

Factors for lubrication-free bearings in construction machinery

The topics are covered are:- Important functions of lubrication in plain bearings

- Reasons for switching to lubrication-free plain bearings

- Differentiation: lubrication-free plain bearings vs. lubricated metallic bearings

- How self-lubricating plain bearings work

- This must be taken into account when changing to dry-running plain bearings

Download now for free (PDF)

Frequently asked questions

Do composite bearings require lubrication?

Like all our bearings, igutex® composite bearings require no lubrication as this is already built into the ‘gliding’ layer. igutex® will also accept lubrication, should this be necessary for your application.

What sizes are igutex® composite bearings available in?

Our composite bearings are available as a sleeve bearing with an internal diameter as small as 20mm up to whatever size you need! They can also be manufactured as a thrust washer with gliding surfaces on one or both sides.

Can igus® composite bearings be machined?

Yes, igus® can provide igutex® composite bearings to your required specification, we are also able to provide guidance on machining – just talk to one of our engineers!

Read our blog