Plain bearing wiki

What you'll find on this page

What is iglidur? ▼

A comparison of different bearing types ▼

Choosing the right shaft material ▼

Installation and tolerances ▼

Free white papers ▼

Test laboratory and test results ▼

Frequently asked questions ▼

What is iglidur®?

Installation and tolerances

Materials

What is iglidur?

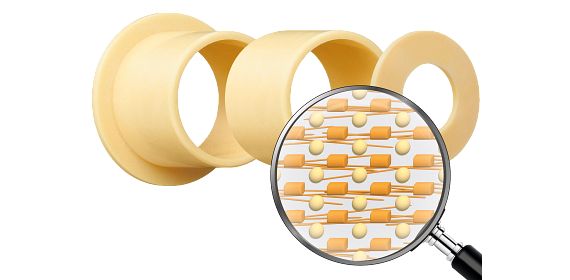

iglidur refers to materials developed by igus. They are made of high-performance polymers and feature special properties such as wear-resistance and suitability for contact with media and chemicals.What are iglidur materials made of? What is behind the self-lubrication effect? Learn more about iglidur plain bearing specifications and composition.

A comparison of different bearing types

There are various plain bearing types to choose from. Each has a different structure and functionality. We have summarised the most important bearing types and will show you their advantages.

Choose the right shaft material

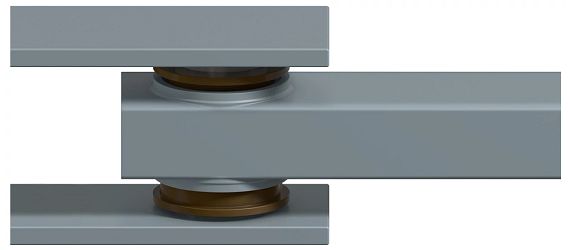

The right choice of shaft and plain bearing plays a crucial role in a well-functioning bearing system. Plain bearings protect the drive shafts and components surrounding the bearing point from wear. These components are often much more expensive, so it is very important that this wear occurs only in the plain bearing, which must be replaced in good time. But the shaft is often neglected during bearing point design. Find out how to properly harmonise the two components.Installation and tolerances

During plain bearing installation, there are a few things to consider that are crucial for error-free function and service life. Find out everything about suitable installation and test methods, clearance specifications, standard tolerances, and the correct way to secure plain bearings.

Free plain bearing white paper

In our free white papers, our plain bearing experts share their insights from practical experience and long-term research and development. They examine different plain bearing technology subject areas to give you an edge.

Questions regarding iglidur® plain bearings? We're here to help.

Send an e-mail

Our employees will contact you by e-mail and reply to your enquiry promptly.

Telephone consultation

On site consultation

Largest test laboratory in the industry

In the iglidur test area, bearings and materials are tested for stress, wear, and friction properties. Other parameters such as high and low temperatures, high loads, and speed are adjusted as the test requires. There are around 50 test systems in the test laboratory, where more than 300 tests are carried out at the same time. We also perform around 11,300 tribological tests on around 250 newly developed plastic compounds every year. To ensure that the new formulations are effective in later use, they are exposed not only to external influences, but also to different movement directions and loads: rotating, pivoting, linear motion, and tumbling.

Results from the igus® test laboratory

Avoid reduced press fit caused by anti-corrosion agentsUsing anti-corrosion agents in the bearing housing can reduce the firmness of the bearing's fit. Find out what anti-corrosion agent increases firmness instead.

Results from the igus test laboratory

How well does gas-nitrocarburisation protect shafts from corrosion?We have investigated what surface treatment best protects shafts from corrosion. Shafts were fitted with iglidur plain bearings and subjected to a 120-hour salt spray test.

Frequently asked questions

What is a plain bearing bushing?

What is a thrust washer?

What is bearing clearance?

What is RoHS?

What is the stick-slip effect?

What information does the pv value give?

For more information, see our FAQ