How well does gas-nitrocarburisation

protect shafts from corrosion?

Shafts with various surface treatments were tested in combination with iglidur plain bearings

Initial situation

Protecting shafts from corrosion is particularly relevant if a bearing point is not to be lubricated. Corroded shafts are not suitable counter partners for a plain bearing. Galvanised shafts are usually not resistant enough in the plain bearing contact area. As a possible alternative, igus® has therefore tested gas-nitrocarburised shafts for corrosion resistance.Would you like to put your bearing to the test? Contact us!

Contact an expert

The test set-up

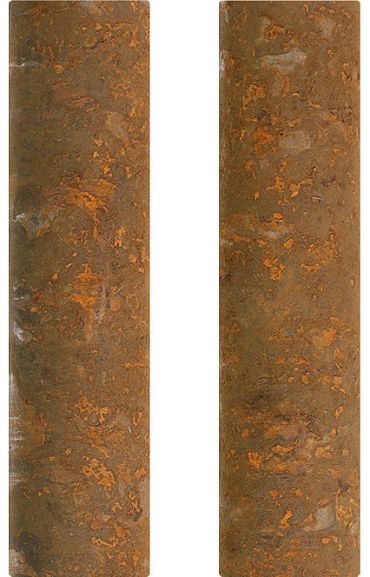

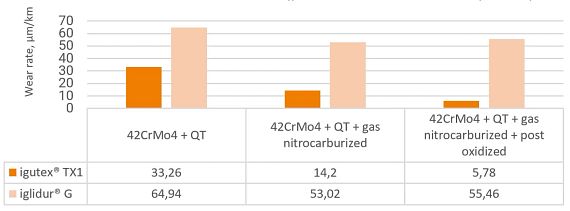

The 42Cromo4 QT shaft material was tested with different surface treatments in combination with igutex TX1 and iglidur G plain bearings. First, a wear test was performed with all plain bearing and shaft combinations. Then the tested shafts were subjected to a 120-hour salt spray test.

Test result

The iglidur® G test results were very good, but igutex® TX1 plain bearings achieved even lower wear rates. The salt spray test shows that the gas nitrocarburised shaft is not well protected against corrosion. But the gas nitrocarburised and post-oxidised shaft exhibits only very slight traces of corrosion. Even in the plain bearing contact area, corrosion protection remains intact after 120 hours of salt spray testing.Visit the shop

Largest test laboratory in the industry

Test laboratory for plastic plain bearings

Plain bearing wiki

To the plain bearing wiki

Personal consulting

Contact an expert now