igus® test laboratory

Proven, predictable, tested

Tech up, cost down - at igus we manufacture our materials and products according to this motto. These offer you a long service life, which extends the operating time of your machines and applications, eliminates maintenance work and reduces costs. Our engineers consider workpiece quality and safety (that is, workpiece resilience and service life) as important criteria in development. Every igus product is tested thoroughly before it is made available for sale. To this end, we have been operating our own test laboratory since 1985. It's not only the industry's largest test laboratory for tribopolymers in terms of area, but it also conducts the highest number of product tests and test procedures.This page offers you the following details regarding our test laboratory

What is tested?

Our facilities for testing applications and materials cover a total of more than 4,000m². Every business sector has its own test laboratory, and we test some product areas together:

- 2,000m² outdoor test area for energy chains and chainflex cables with particularly long travels

- 1,500m² test area for chainflex cables in our own energy chains

- 300m² test area for iglidur plain bearings, drylin linear bearings and Low Cost Automation - the latter partly under real conditions in quality assurance

- NEW: 200m² test area for igus:bike and bicycle components

To be able to develop new cleanroom-compatible products more quickly, we operate our own cleanroom laboratory with an ISO Class 1 cleanroom system in cooperation with the Fraunhofer IPA. An outdoor testing area, a laboratory for noise tests and the climatic chamber with -40°C complete our test area. To achieve maximum realistic conditions, we also test customer applications and conduct standard industry tests.

We would love to test your application as well

You don't want to make experiments and would like to subject your application to a material test before using it? Or you have an unusual application for which you need a suitable component? No problem! We will test your application in our test laboratory and use our know-how to find the best igus solution for you. No matter whether plain bearing, energy chain, cable, linear technology, bar stock or Low Cost Automation.

Laboratory test enquiry

How many tests are conducted in the igus laboratory?

Annually, a large number of tests and material examinations are conducted in the numerous test facilities:

- Over 15,000 tests in total, including around 4,000 for e-chains and chainflex and around 11,000 for dry-tech (rotating, swivelling, linear, tumbling, heated, underwater etc.).

- 10 billion e-chain cycles

- 3,500 tested cables

- 450 test rigs for bearings

- 400 customer-specific tests

What happens to the test data?

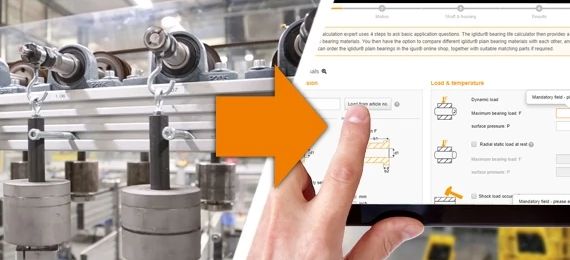

The use of testing data does not stop after development. We have been developing innovative online tools since 2001 and sensor-based smart plastics since 2016, which use the database of our test laboratory results. With these tools, the economic efficiency and reliability of our products can be determined quickly and very easily online around the clock. This means a high degree of transparency for our customers, enabling engineers to find the most cost-effective, functioning solution to their problem. More than 40 tools are available to you free of charge, including:

Have a virtual tour through the laboratory

Would you like to take a look around our laboratory?

No problem: you can visit all areas easily from your home or your office via a virtual tour. Just click on the button below, select the desired lab area on the home page and follow the arrows to the next stop of your visit. Click on the numbers for more information about the tested product.

Start 360° tour now

The different areas of the test laboratory

... by product area

chainflex® test lab

... by application area

Tribology and tribopolymers

Tribology is the core of our motion plastics

The use of wear-resistant materials and maintenance-free components not only saves money but also reduces the risk of wear-related equipment failure or extensive maintenance work. igus has acquired considerable know-how in tribology and a large amount of data in the test laboratory - ideal conditions for all mechanical engineers. The reason: machines today are often used to capacity in three-shift operation. In the light of the growing challenges, searching for the tribologically optimised component is time well spent for every plant manufacturer.

Tribology infographic