Avoid reduced press fit due

to anti-corrosion agent

iglidur® plain bearings were tested in combination with various anti-corrosion agents

Initial situation

If a bearing position is to operate 100% without lubrication, it may be advisable to treat the bearing mount with an anti-corrosion agent. These agents can reduce the tight fit of the bearing.

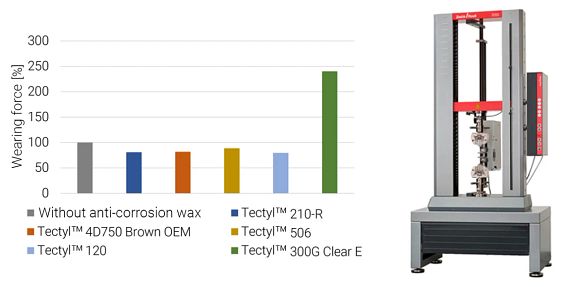

Test: displacement force with different anti-corrosion agents

The test shows that almost all anti-corrosion agents reduce displacement force. Only TectylTM 300G Clear E enhances press fit.

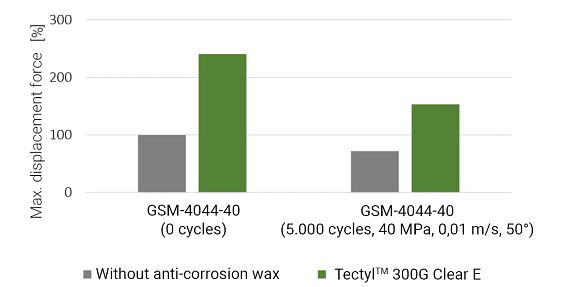

Result: TectylTM 300G Clear E under the influence of motion and force

Even under the influence of motion and force, TectylTM 300G Clear E can achieve a tighter bearing fit. In the test, it is almost twice as tight as a plain bearing without anti-corrosion agent.

Largest test laboratory in the industry

Test laboratory

Plain bearing wiki

To the plain bearing wiki

Personal consulting

Contact an expert now