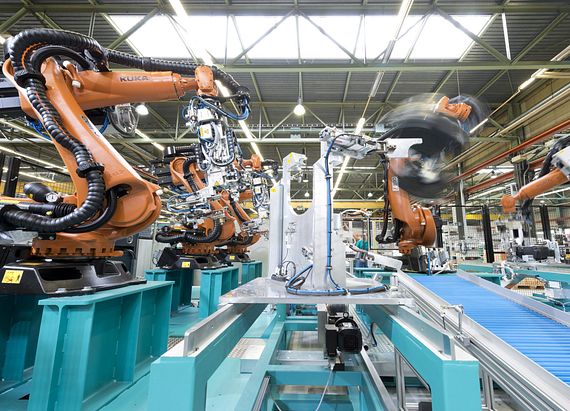

Motion plastics for car body construction

Energy safely guided in all directions

The process flows smoothly in car body construction. If a machine part stops, the entire production line breaks down.

To protect electrical and pneumatic cables and supply hoses for robots from sparks and debris, under complex torsional movements, igus® has developed the triflex energy chain.

It is ideal for multi-axis movement and is easy to install, maintain and adjust.

Would you like more information about igus® parts used in the automotive industry? Our experts will be happy to get in touch with you.

Suitable products for Automotive production

Harnessed dress packs

- Consisting of a triflex® R e-chain,

- Completely filled with chainflex® cables and hoses

- Supply of energy, data and media

3D chain triflex® R

- Specially developed for multi-axis robots

- Defined bend radius

- High tensile strength and high flexibility

- Easily openable and fillable

Retraction system triflex® RSE

- Linear retraction

- Lightweight and space saving

- Fewer deflection points, higher process reliability also for LLK and supply hoses

Ready-made cable packages AIDA

- Ready-to-connect AIDA extension cables for automation

- 50% reduced assembly effort due to push-pull technology

Condition monitoring for e-chains®

- Special sensors detect chain breakage in the initial stage

- Prevents overloading and subsequent system failure

Pre-assembled e-chain® systems

- Eliminate storage costs for cables, e-chains® and connectors

- Cut installation times by half

- Minimise your machine downtime

Successfully in use

Two-thirds fewer failures with triflex R energy chain

Jaguar Cars Limited needed to find a new cable guide for the automated industrial robots for a car factory. The previous solution with hoses caused high downtime as the hoses dropped into the robot's working range after some time. The newly installed triflex RS universal module, on the other hand, pulls the cables back again with every movement.

Failure-safe and high cost savings, thanks to triflex R 3D chain

Harsh operating conditions and high acceleration forces led to expensive downtimes for handling robots in MA Automotive's machinery park. Because, the assembled dress pack snagged, stuck and tore off again and again. The customer saves the high maintenance costs of €100,000 per year after converting to flat triflex RS energy chain systems.

Safe cable guide on rotary axis thanks to twisterchain

In a retrofit process, all axes of a 6-axis robot have now been equipped with multi-dimensionally moving energy chains. In addition to the 3D chains on the robot arm, twisterchain energy chains are used on the rotary axis to guide cables and hoses. Since then, there has been no more downtime.

High flexibility and cable protection on 11 assembly robots

An essential component of turnkey assembly lines for the automotive industry today are robots. They have to function and usually do hard labour. Multi-dimensionally moving energy supply systems ensure maximum flexibility and the longest possible service life for all complex movements - while at the same time being easy to assemble.

Success stories

Two-thirds fewer failures with triflex R energy chain

Jaguar Cars Limited needed to find a new cable routing for the automated industrial robots for a car factory. The previous solution with hoses caused high downtime as the hoses dropped into the robot's working range after some time. The newly installed triflex RS universal module, on the other hand, pulls the cables back again with every movement.

... and more success stories

Discover other customer applications where our motion plastics are used to demonstrate their benefits.

- We plan the optimisation of your system to guarantee maximum service life

- Upgrading your existing machines

- Retrofitting igus products with condition monitoring or predictive maintenance

- Our energy chains are also available as a readily harnessed system, e.g. dress pack, 7th axis

- After installation: regular inspection and maintenance of your energy chains and condition-monitoring systems

- At the end of the life cycle, we will take the energy chain back and recycle it