Examples of successful applications in automobile production

Press plant

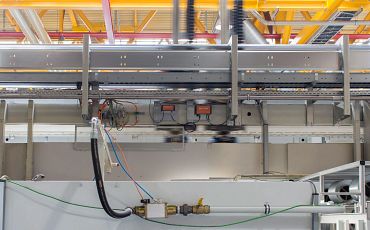

Energy safely guided in high-speed sheet feeder

By using linear motor technology, Strothmann GmbH has set new standards in terms of performance and speed. The energy supply with the E6 is perfectly tailored to the high speed and acceleration values

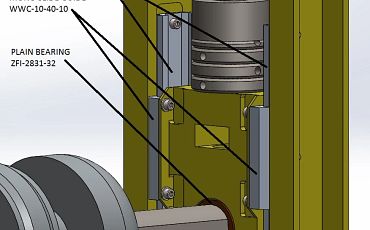

Precise and maintenance-free bearings in rolling machine for mudguards

In a rolling machine for aluminium profiles for the production of lorry mudguards, steel bearings were previously used for the lifting system of the pressure roller. Since these always had to be lubricated and they were not precise in function, they were replaced by completely lubrication-free and maintenance-free drylin W linear rails and iglidur Z plain bearings.

Car body construction

Two-thirds fewer failures with triflex R energy chain

Jaguar Cars Limited needed to find a new cable guidance for the automated industrial robots for a car factory. The previous solution with hoses caused a lot of downtime because the hoses fell into the robot's workspace. The newly installed triflex RS universal module, on the other hand, pulls the cables back again with every movement.

Safe cable guide on rotary axis thanks to twisterchain

In a retrofit process, all axes of a 6-axis robot have now been equipped with multi-dimensionally moving energy chains. In addition to the 3D chains of the triflex R family on the robot arm , twisterchain energy chains are used on the rotary axis to guide cables and hoses. Since then, there has been no more downtime.

Failure-safe and high cost savings, thanks to triflex R 3D chain

Harsh operating conditions and high acceleration forces led to expensive downtimes for handling robots in MA Automotive's machinery park. The customer saves the high maintenance costs after converting to flat triflex RS energy chain systems.

High flexibility and cable protection on 11 assembly robots

The triflex R energy supply systems are ideal for robot applications in the automotive industry as they offer a high level of flexibility and at the same time a high level of cable protection. A twist up to approx. +/- 380° per metre in the longitudinal axis is possible and limited by a clear stop-dog.

Paint shop

Reliable in the paint mist – multi-dimensionally moving energy chain

Since its installation more than two years ago, the multi-dimensional energy supply system triflex R, has ensured error-free painting and round-the-clock availability of the painting robot. The simple connection significantly reduces setup times.

Maintenance-free bearings for actuators in paint lines

At ARIS Stellantriebe GmbH, various iglidur plain bearings as well as a dryspin high-helix thread lead screw are now used in the actuator. The iglidur material can optimise function and bring cost down at various points in the drive.

Drive train

No unplanned outages due to intelligent energy chain monitoring

The automotive industry relies on lightweight and quiet plastic energy chains from igus. In addition, these can be equipped with products from the smart plastics family isense. This allows the condition of the energy chain systems to be digitally monitored.

Lubrication-free linear bearings in washing machines for motor components

In this industrial washing machine used to remove dirt from motor components before installation, conventional linear ball bearings failed. Due to the highly corrosive environment and the use of aggressive cleaning agents, our iglidur polymer bearings are now in use. They provide the required reliability and maintenance-free operation in the system.

E-drive train

Reliable energy supply at maximum process speed

The company Flexweld Robotic welding was looking for a complete system for the safe guidance of all energy cables, cooling tubes and air hoses in an energy supply. The solution to this was the energy chains from the triflex R family.

Final assembly

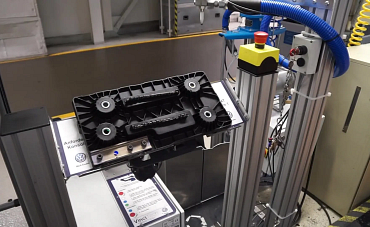

Automated application of glued seams

Low Cost Robotics is also ideal for automobile production. Volkswagen uses a robolink robot arm from igus. The robot arm undertakes the gluing of acoustic elements in the area of the rear battery console. Find out how you can automate your processes

10 years of success in handling systems

For over 10 years, Husch Handhabungstechnik GmbH has been relying on our plastic energy chains as well as linear and rotary bearing products for their handling systems. They enable long service life, robustness and freedom from maintenance.

Roller energy chains for highly dynamic loading linear robot

The P4.32 rol energy chain runs quietly and smoothly and can withstand sustained high speeds. This makes them perfect for use in the loading gantries of the GROB-Werke GmbH

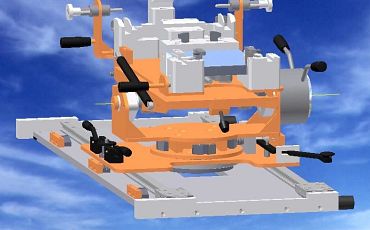

Flexible and resilient slewing ring bearings in assembly supports

In its assembly line, a car manufacturer relies on our iglidur slewing ring bearings for a total of 60 assembly supports, as they are very light and still function permanently without maintenance and lubrication under high and constant loads.