Quick and easy: kitchen automation with motion plastics

The kitchen of the future is flexible, modular and does the work for you if necessary. Fast and maintenance-free cooking robots are becoming increasingly interesting, especially for fast food restaurants, as they help to close staff gaps, speed up processes and shorten waiting times. For this, we have the right bearing technology, energy supply and low-cost robotics in our range. Your benefits:

- No machine downtime: components can be calculated online

- hygienic & dirt-resistant, FDA-compliant if required

- Save installation space and weight

Contact an expert

Build or buy

Delta robot for food use

- 660mm workspace diameter with 180mm of working height

- Pick rate of up to 30 per minute

- Self-lubricating, maintenance-free drylin ZLW toothed belt axes

- Ready to connect with stepper motors and a dryve D1 motor control system

Selected motion plastics for a fully automated kitchen

drylin delta robot

- 660mm workspace diameter

- Pick rate of up to 30 per minute

- Self-lubricating, maintenance-free components

drylin ZLW 7th axis for robot

- Flexible robot use instead of locking kinematics

- Adapter kit incl. Preparation of suitable e-chain systems

- Integration into the igus robot control

More about drylin ZLW

drygear modular gearbox system

- Application temperature: +5°C to +50°C

- Suitable for spray water

- Lightweight

- Lubrication-free

More about drygear Apiro

iglidur A160 plain bearing

- Compliant with FDA and EU regulations governing chemicals and food

- Complies with Regulation (EU) No. 10/2011

- High media resistance

Find out more in the shop

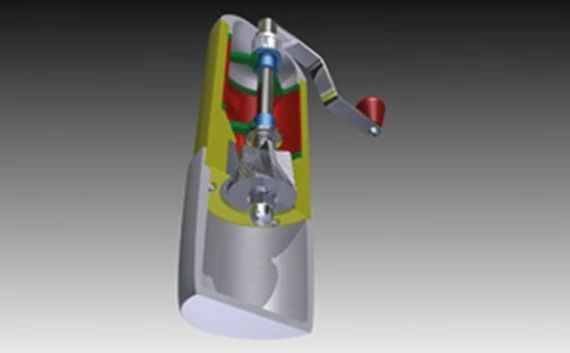

Rod end with female thread

- Detectable rod end for the food industry: made of materials compliant with FDA regulations and EU 10/2011

- New design gives dirt no chance

Discover igubal KCRM now

E2.1 e-chain

- Quick, easy filling

- Integrated brake for smooth, quiet operation

- Reduce installation space with small bend radii as low as 28mm

More about E2.1

Setting options on a new level

A kitchen with innovative technology in a contemporary design in all movable furniture elements. We offer the right bearing technology and energy supply for this. They are exactly the right products to enable movements to run smoothly, quietly and maintenance-free.- drylin W hybrid bearings and e-chains from the E14 series for height adjustment of the work module

- Self-adjusting igubal double joints for moving wall cabinets

- drylin E DC motors for drawer system

Where motion plastics are already being used successfully

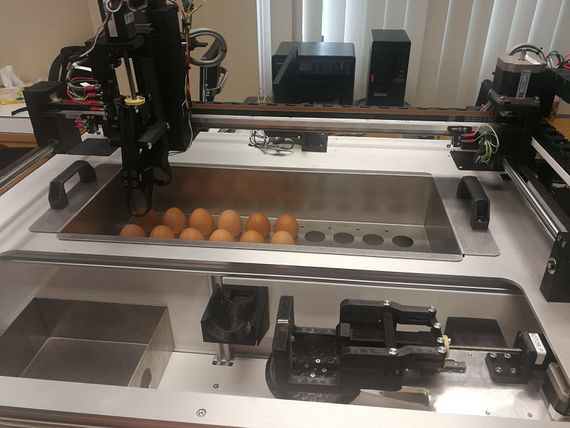

Modular and hygienic egg breaking machine

The company JSL Solution Pte Ltd has developed a machine for breaking half-boiled eggs. The machine can crack and distribute the eggs at the touch of a button, ensuring the freshness of the eggs. The egg is automatically transported from a tray to the cooking plate and separated. The empty egg shells are then transported to a separate compartment.

The maintenance-free and lubrication-free components are suitable for food applications with the highest hygiene requirements.

The maintenance-free and lubrication-free components are suitable for food applications with the highest hygiene requirements.

Find out more about this application

Lubrication-free linear axes in automated cocktail mixer

With the “CocktailAvenue”, a start-up company in Friedrichshafen has invented a completely new way of mixing cocktails: a machine takes over this task. Automation technology thus opens up a new, exotic area of application. Also included: drive systems and energy chains from igus.

More about the application

Maintenance-free dosing of mixed drinks

This participant is showing a completely new product in our manus competition: a fully automatic cocktail machine. At the touch of a button, “The Qube” mixes cocktails and long drinks from up to 12 bottles.

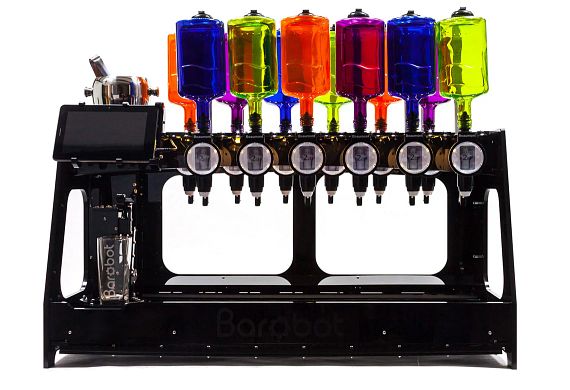

drylin spherical insert bearings in the bartender robot

A robot that replaces the bartender at a house party: that's the idea behind Barobot, developed by two inventors and founders of a Polish start-up. The machine can independently produce 1,000 cocktails from 12 bottles. For the transport carriage, which glides on a steel rod and moves the glass to the bottles, the developers were looking for a bearing with as little play as possible that is quiet, food-safe and cost-effective. Conventional metal ball bearings were not satisfactory. At igus, the perfect solution was found in drylin linear spherical insert bearing ...

More about the application

Corrosion-resistant linear guide for coffee machines

This coffee machine brews coffee at the perfect temperature. A drylin N low-profile linear guide system guides the hot water through the machine into the coffee filter. The decisive factors for choosing the plastic guide were its resistance to corrosion from water and water vapour and its smooth movement with absolute freedom from lubricants.

Lubrication-free plain bearings for coffee grinder

The grinder grinds coffee beans into very fine powder. To ensure optimum ground coffee quality, the grinder mechanism must operate consistently and precisely. The bearings must also be very strong and not become clogged with coffee dust. Our lubrication-free iglidur plain bearings ensure this.

Bearing components in a pizza vending machine

This innovation from the fast food sector can bake a deep-frozen, pre-baked pizza within two minutes and serve it to the customer. Among other things, the machine features a new type of infrared high-performance oven. The pizzas are stored in a deep-frozen state. All bearing components used must therefore function at -20°C.

Tested in the test laboratory for use in the real world

All products are tested for wear and durability under real-life conditions in the igus test laboratory, the largest in the industry. The results are entered into our service life calculation tools for precise durability predictions.Upon request, igus carries out customer tests to check product use under completely tailored conditions.

More about the igus test laboratory

What are the most important regulations for food sector vending machine manufacturers? How can installation space be saved in the face of a growing product range? The igus blog features interesting articles on vending machine technology.

Take a look now!