igubal® bearing elements application examples

igubal® bearing elements can be used without problems even in harsh environments and are maintenance-free. They are corrosion-resistant in humid environments. The operating temperature is from -30°C to +80°C. Seals are not necessary, even in extremely contaminated conditions. This is true for fine dust as well as coarse dirt.

Every year, igus® engineers develop more than 100 new plastic compounds and conduct more than 3500 tests on maintenance-free plain bearings every year, and thus over the years has established a large database of polymers' tribological properties.

Every year, igus® engineers develop more than 100 new plastic compounds and conduct more than 3500 tests on maintenance-free plain bearings every year, and thus over the years has established a large database of polymers' tribological properties.

More applications

High sea catamaran

and the first one that is variably adjustable in its width.High sea catamaran

Test stand for control centres

Only extensive earthbound testing can demonstrate the suitability of components for space applications.Test stand for control centres

Plastic spherical bearings for electric wheelchairs

Lubrication- and maintenance-free plastic bearings provide the required functional reliability in electric wheelchairs.Plastic spherical bearings for electric wheelchairs

Lubrication-free linear and spherical bearings for baked goods gripper

This gripper picks up freshly baked goods from a conveyer belt and packs them in baskets.Lubrication-free linear and spherical bearings for baked goods gripper

Plain and spherical plain bearings withstand strong vibrations in grain sorters

This machine cleans and sorts all types of grain. Articulated and plain bearing technology enables the long-lasting and maintenance-free function.Plain and spherical plain bearings withstand strong vibrations in grain sorters

Bearing technology and energy chains for electric aircraft

To achieve the best flying conditions, all components must be lightweight and at the same time as durable as possible.Bearing technology and energy chains for electric aircraft

Bearing technology for Mars robots

This robotic vehicle is designed for a very special environment: it will one day be driving on Mars.Bearing technology for Mars robots

Plain and spherical bearings in the prosthetic joint

This joint is a new development for use in prostheses. Plain bearings made of iglidur J and igubal spherical bearings are installed in it.Plain and spherical bearings in the prosthetic joint

Spherical bearing for solar aeroplane

The prototype of the „Sunseeker Duo“ solar plane is the world‘s first solar-powered two-seater.Spherical bearing for solar aeroplane

Gritting unit

The screw conveyor of the spreader unit must be with movable bearings in order to be able to compensate for axial misalignment and dynamic movements in the screw.Gritting unit

CD/DVD industry

Plastic rod end bearings provide for high plant availability.CD/DVD industry

Equipment manufacture

Lubrication-free tribopolymers in extreme application - Packaging unit for profiles.Equipment manufacture

Fertilizer spreader

A dynamic test of the robust igubal clevis joints in these fertiliser spreaders proved a service life of at least 10 years.Fertilizer spreader

Current consumer

igubal® spherical bearings as insulating components in current consumers of the subway.Current consumer

Water regulation system

The used clevis joints and rod end bearings are corrosion-free and usable in liquid media.Water regulation system

Fully automatic tire fitting lines

No more expensive repairsFully automatic tire fitting lines

Bearing technology for helicopter drone

Light and free from playBearing technology for helicopter drone

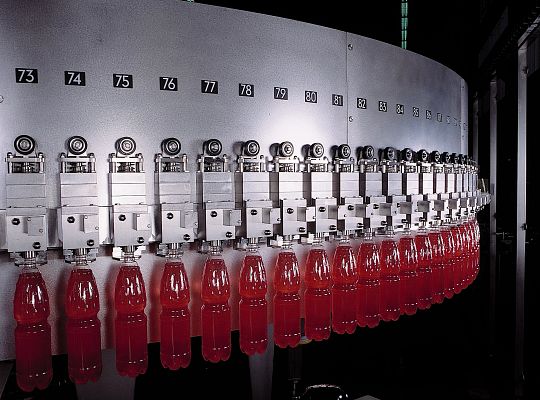

Plain bearing for filling valve in beverage bottling plant

The challenge: The operating temperature is maximum 140°C and the applied material must be resistant to all cleaning agents used in the beverages industry.Plain bearing for filling valve in beverage bottling plant

Bearing technology for ultra-light gyrocopters

iglidur® G is the problem solver in this rotor head The rotor blades rotate about 400 times per minute and thereby execute oscillating motion with maximum 30°.Bearing technology for ultra-light gyrocopters

Special bikes and therapeutic accessories

Plain, spherical and linear bearings made of plastic help to improve mobility and the quality of lifeSpecial bikes and therapeutic accessories

Soccer table

Application of a high-value spindle lift table with steep-threaded spindle, linear guide systems and igubal® spherical bearings.Soccer table

PLC laboratory trainer

The aim of the concept is to demonstrate to the students how to handle a programmable logic controller (abbreviation: PLC) in an attractive way.PLC laboratory trainer

Long service life in bag forming, filling and sealing machine

Maintenance-free plastic bearing defy all outer influences and provides for the required service life.Long service life in bag forming, filling and sealing machine

Bearing technology, energy chains and cables for straightening machine

Quick, straight, precise: this is how the requirements in sheet metal machining can be summarized. Sophisticated straightening technology makes all this possible.Bearing technology, energy chains and cables for straightening machine

Bag forming, filling and sealing machine: Hygienic design of the format adjustment

For this vertical bag forming, filling and sealing machine, absolute freedom from maintenance over the entire life cycle of the machines was particularly important to the customer.Bag forming, filling and sealing machine: Hygienic design of the format adjustment

Cow cleaner

Lubrication-free polymer bearing technology for cow cleanersCow cleaner