Special R&D measurement setup

Art Robotics is a Belgian tech start-up active in the fields of robotics, IoT and AI. The company would like to act exceptionally sustainably and use modern technology, e.g. for robotic solutions in energy and recycling technology.

The company was commissioned to develop a new measuring system for their customer Unimore. You can read about the special features and challenges of this order in this application report.

The company was commissioned to develop a new measuring system for their customer Unimore. You can read about the special features and challenges of this order in this application report.

Profile

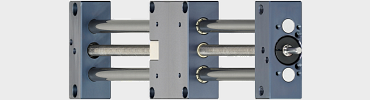

- What was needed: two different lead screw axes, motor and motor control system

- Requirements: research and development in the field of sustainability requires innovative, cost-effective and, above all, individual solutions. Furthermore, the solution had to be suitable for cleanrooms

- Industry: Robots

- Success for the customer: our lubrication-free lead screw axes, in combination with the motor and control system, ensure a cost-effective, turnkey solution.

More application examples

Products used

Configure lead screw axis

Are you still looking for the right linear module? Configure your desired product now.Go to the configurator

Problem

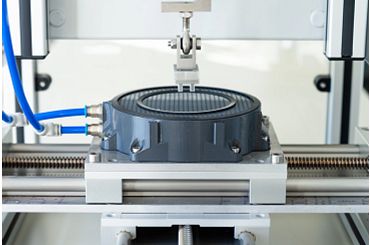

Belgian company Art Robotics uses smart technology to create smart, sustainable solutions for the energy and recycling industries. The core competencies are in the areas of robotics, IoT and AI.Art Robotics faced a special challenge with one of their customers called Umicore. Umicore is a leader in circular materials technology, producing materials for high-performance optoelectronic, photovoltaic and electronic devices. The company's R&D department is constantly looking for new methods to offer cost-effective materials with the same quality, lightweight and less waste. In order to support these innovation processes, new measurement systems and tools for wafers are needed.

The problem: these are not available off the peg and have to be developed from scratch. An experienced partner is needed who develops innovative, turnkey solutions quickly and cost-effectively. Furthermore, the system had to function in a cleanroom environment.

Solution

Art Robotics developed a completely new solution with the help of the igus® components. All components, e.g. the lead screw axes, the motor and the motor control system were integrated into a complete system that was able to meet the customer's requirements. The result: a special measurement setup for quantifying the specifications of wafers.The system, which consists of parts from igus® drive technology, among others, can handle very thin next-generation wafers (< 200µm) as well as apply high forces in a controlled manner and provide accurate measurements. The plug-and-play software with a special graphical user interface, in combination with the D1 motor control system, enables easy configuration and measurements.

Since the measurements are carried out in a cleanroom environment, all components are suitable for cleanrooms. It is a desktop system that is compact, ergonomic and safe to use. Just like the products from igus® drive technology, the system is designed for modularity in order to expand its capabilities in the future.

Impressions

More application examples

3D printer for concrete l Lubrication-free solution for dusty environment

The use of cement creates a high level of dust load in the 3D concrete printer, which the products have to withstand. Furthermore, the longest possible service life and fast maintenance are required. Our bearing solutions and lubrication-free toothed belt axes ensure a long service life despite dirt load.

Go to application

Electric drive technology in an automated positioning system

Unlike traditional recirculating ball bearing systems, drylin® linear plain bearings operate on sliding elements. This application overview shows you a wide spectrum of applications for maintenance-free linear guide systems from the drylin® product range.

Go to application

Linear axis for precision, clearance-free welding seam bend testing device

Munsch Kunststoff-Schweißtechnik GmbH uses lubrication-free linear axes and linear bearings from our drylin® product range for its weld seam bend testing equipment. The testing device was part of a practical project by trainees at the company. The testing device works so well that it's now entering series production.

Go to application

Lubrication-free linear axis for automated cocktail mixer

With the “CocktailAvenue”, a start-up company in Friedrichshafen has invented a completely new way of mixing cocktails, leaving the task for a machine. Automation technology thus opens up a new, albeit rather exotic, area of application.

Go to application

Drive technology online shop

Go to the online shop

Drive technology configurator

Go to the configurator

Download whitepaper

Download whitepaper