Robot cables for 3D movements

What is a robot cable?

The complex movements in industrial applications demand twistable and/or three-dimensionally moving cables with a long service life. For example, a movable robot arm generates high bending, centrifugal and torsion forces in a robot cable. The chainflex® robot cables have been specifically designed and tested for this requirement.

A wide selection of twistable chainflex® CFROBOT cables are available, such as shielded single cores, motor cables, servo cables, measuring system cables, bus cables and hybrid and control cables. In contrast to conventionally constructed copper shields with braiding, the CFROBOT generally uses a torsion-resistant, tinned copper shield stranding.

To the chainflex® cables overview

Would you like more information about chainflex® cables? Our experts will be happy to get in touch with you.

Contact an expert

Are you familiar with our online tools?

Simply find and choose a suitable type, calculate its service life and order it onlineChainflex® product finder

Find the right cable for your application quickly and easilyTo the product finder

Service life calculator tool

Calculate the service life of any chainflex® cableTo the service life calculator

chainflex® robot cable options

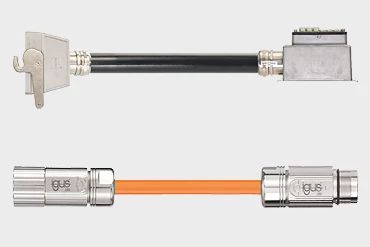

chainflex® motor cable CFROBOT

- For twistable applications

- Flame retardant

- Hydrolysis and microbe-resistant

Visit the shop

Harnessed cables for robots

- For a full overview of all readycable® drive cables available you can visit the overview page here.

Visit the shop

Special structure and specifications of a chainflex® robot cable

Cores, stranded structure, shields and jacket materials must compensate for high alternating bending loads as well as cable diameter changes due to torsional movements. Filling elements are used which can absorb occurring forces such as torsions. For this purpose, PTFE elements and rayon threads are installed. This "mechanical stress" differs greatly between cables in a linear e-chain® system and a cable subjected to bending, torsional and centrifugal forces. This cannot usually be determined in advance. The igus® Torsion Test Standard was developed for this purpose. This standard allows a reproducible assessment based on meaningful test results. All CFROBOT cables with a fixed end distance of one metre are twisted at least 5 million times.Discover results

triflex® R readychain® robot hose package

In production plants, high durability of components and the lowest possible downtime are the priority. With a triflex® R readychain® robot dress pack, both are combined and optimised. We develop a customised dress pack system, consisting of triflex® R, chainflex® and igus® connectors:- Eliminate storage costs for cables, e-chains® and connectors

- Cut lead times by half

- Flexible response to order fluctuations

- Minimise your machine downtime

- Reduce the number of subcontractors and related orders

Find out more

Application example

chainflex® cables for demanding robot applications

Wandres GmbH specialises in the development and production of brushing and air cleaning systems. The safe and careful removal of dust, fibres and the smallest particles on surfaces is a prerequisite for many production processes in order to produce high-quality products. In order to protect the 6-axis robots from mechanical damage, the robot cables were equipped with factory-supplied protective hoses. However, these could not stand the continuous operation and are permanently torn or frayed, causing the whole test facility to come to a standstill.

Find out more