The drylin® linear axes with toothed belt drive are suitable for many positioning and adjustment tasks. The lubrication-free drylin® W profile guide acts as a linear guide and a toothed belt acts as a drive. The stroke is individually selectable. Thanks to the lightweight design using polymer and aluminium, igus® linear axes with toothed belt drive have a low mass inertia, making them highly efficient.

Both in confined installation spaces and in applications requiring high torque support, the series of linear units with toothed belt drive offer the right solution; both as a single system and in gantry designs. All drylin® toothed belt axes can be ordered with ready-to-connect configurations with drylin® E stepper and DC motors.

Would you like more information about the drylin® ZLW toothed belt range or do you need an individual consultation? Our experts will be happy to get in touch with you.

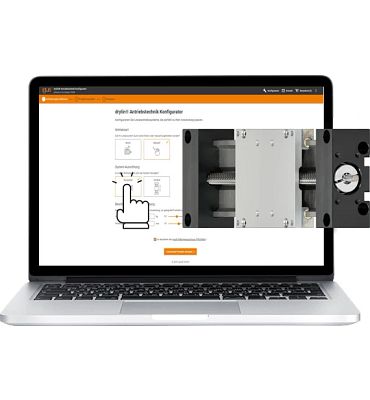

The drive technology online configurator gives you the right drive technology system after you enter your requirements. You also have the option of requesting or ordering motors and other accessories, such as the motor control system.

Toothed belt material?

Maximum stroke length?

Weight without stroke?

You can find answers to important technical questions and an overview of all data here

Monday to Friday from 8am - 8pm.

24h