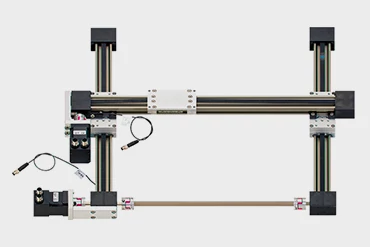

drylin® drive technology is based on the plain bearing principle instead of recirculating ball bearing systems. This results in much less noise and vibration. For you as the operator, the application with the linear unit is up to four times quieter.

drylin® drive technology distinguishes itself from its metallic counterparts not only with its technical advantages, such as freedom from lubrication and maintenance, but also costs up to 30% less. The linear drives of the drylin® ECON series are particularly cost-effective.

The use of cement creates a high level of dust load in the 3D concrete printer, which the products have to withstand. Furthermore, the longest possible service life and fast maintenance are required. Our bearing solutions and lubrication-free linear drives ensure a long service life despite dirt and contamination.

The term drive technology refers to the discipline that is generally concerned with technical systems for generating motion by transmission of force. The term "drive"refers to the supply of energy to machines to be driven and the control or circuit of their drive components.

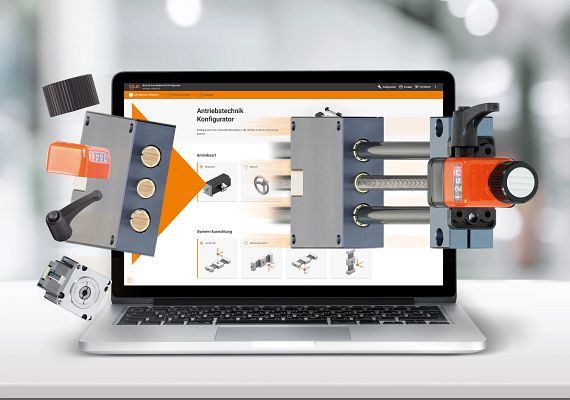

You can use the igus® drives configurator. This will help identify the ideal system based on the parameters you input.

As with all igus® products the linear drives are self lubricating, dirt-resistant and affordable.

Monday to Friday from 8am - 8pm.

24h