Fly One® provides media such as electricity, data, gas, and compressed air in the room where it is needed - safe and precisely positioned. It offers maximum flexibility in four axes.

If needed, Fly One® unfolds fully and automatically and can be navigated in three dimensions to any position. Then, at the touch of a button, it folds up again fully, automatically and from any position and retracts discreetly into the ceiling.

Fly One® is used in educational institutions, workshops, and laboratories, generating flexible room concepts for such activities as learning, working, and research.

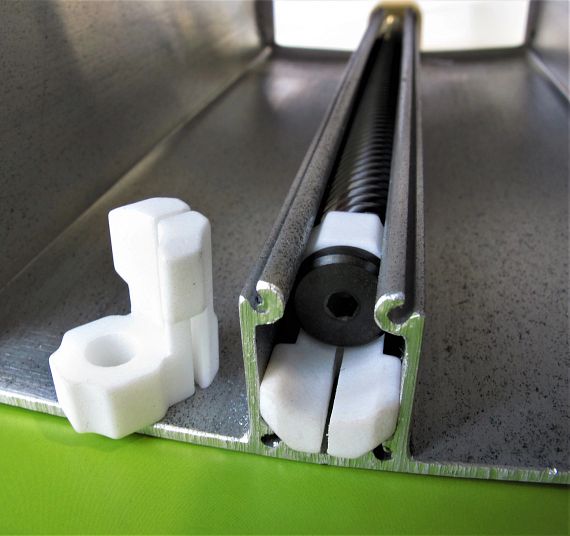

The drive mechanism uses polymer plastic components to ensure quiet, maintenance-free operation. Additive manufacturing is used for integral components that replace many conventional design elements. Guiding, supporting, dampening, connecting ... lightweight, quiet, and without maintenance, all in a single plastic component. These plastic all-rounders reduce assembly times. Gliding joints are integrated into the Fly One® housing part injection mould.

Michael Richert from Hohenloher Strategic Purchasing says, "We rely on economical plastic plain bearing solutions. The component architecture of our Fly One® is limited to what is absolutely necessary to achieve the best possible."

The cooperation with igus is smooth: "We have been working with igus right from the start of our development efforts in a successful partnership. We use their immense solution portfolio, extensive experience, and fast, direct support."

igus has many ways of supporting an application and presenting products simply. This can be in person, virtually, or by phone. We have a team of engineers and local colleagues to support the customer on site.

Various digital platforms can also be used to obtain more information about dryspin lead screw technology. They range from our tools to blog articles and FAQs to YouTube videos.

Monday to Friday from 8am - 8pm.

24h