Electrical adjustment system

Lubrication-free solution for professional espresso machines

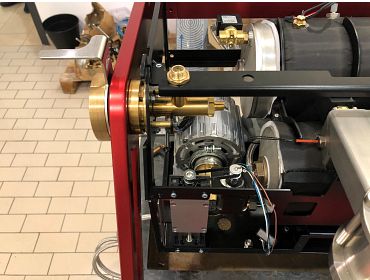

The Italian company develops professional coffee machines under the brand name "CIME". These are always state-of-the-art, as even existing models are constantly being improved through the development of new versions. CIME also attaches particular importance to the reliability, robustness and performance of their machines.To develop a new espresso machine, the company looked for suitable components that meet the quality standards. The goal is a lubrication-free electrical adjustment that can withstand dirt and high temperatures. In this application report you will find out what other special features and challenges this order entailed and how igus® was able to solve them.

Profile

- What was needed: Lubrication-free lead screw axes and matching stepper motors

- Requirements: Robust components that function even under high temperatures and potential contamination. All components should also be free of external lubrication.

- Industry: food industry

- Success for the customer: Our lubrication-free lead screw axes in combination with the motor provide a turnkey solution.

Products used

Configure lead screw axis

Are you still looking for the right linear module? Configure your desired product now.Problem

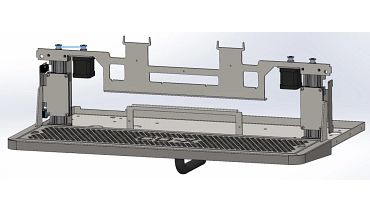

Components within a coffee machine have to withstand various challenges every day. For this reason, the CIME company was looking for robust solutions for a new espresso machine. The requirements were very varied: on the one hand, high temperatures arise in a coffee machine due to the heating of the water, and on the other hand, water, coffee or coffee powder are also expected to come into contact with the individual parts and contaminate them. Therefore, all possible solutions involving the use of lubrication were excluded.Another special feature is that it is not a normal coffee machine, but a state-of-the-art espresso machine with electrical adjustment. The collecting area on which the espresso cups stand should be adjusted automatically. For this reason, sliding ability is also a crucial criterion. Furthermore, the parts should be as maintenance-free as possible.

Solution

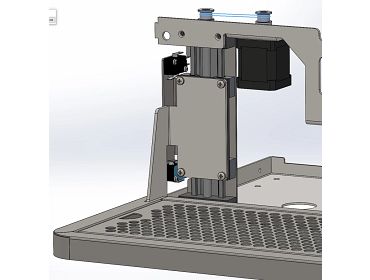

With the help of igus® components, CIME developed an electrical adjustment system for the espresso machine that could meet all requirements. The system developed includes the use of two drylin® linear guides SLW-0630 and two stepper motors that work synchronously.The movement is transmitted via pulleys and belt connections. There are also two micro-switches for upper and lower limit switches. An ad hoc software was developed that enables height adjustment via a touchscreen. The user can choose between an automatic setting and a manual setting.

The selected products do not require the use of external lubrication and are therefore not only maintenance-free, but also insensitive to contamination.

Impressions

More application examples

Offshore robot for tough environments

Special measurement setup with lead screw axis, motor & control system

Research and development in the field of sustainability requires innovative, cost-effective solutions that are suitable for cleanrooms. Our lubrication-free linear axes with lead screw drive, in combination with the motor and control system, ensure a cost-effective, turnkey solution.

3D printer for concrete l Lubrication-free solution for dusty environment

Electric drive technology in an automated positioning system

Linear axis for precision, clearance-free welding seam bend testing device

Munsch Kunststoff-Schweißtechnik GmbH uses lubrication-free linear axes and linear bearings from our drylin® product range for its weld seam bend testing equipment. The testing device was part of a practical project by trainees at the company. The testing device works so well that it's now entering series production.

Lubrication-free linear axis for automated cocktail mixer

With the “CocktailAvenue”, a start-up company in Friedrichshafen has invented a completely new way of mixing cocktails, leaving the task for a machine. Automation technology thus opens up a new, albeit rather exotic, area of application.

Drive technology online shop

Drive technology configurator

Download whitepaper