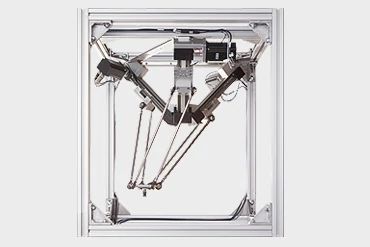

Sprue pickers within injection-moulding machines

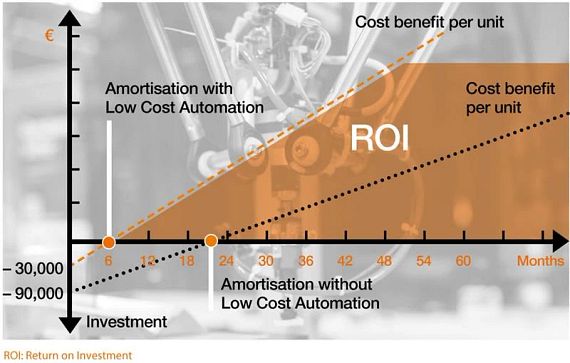

Quick return on investment after only a few months

Automation is essential for optimising operational processes and ultimately for increasing competitiveness. There are many automation solutions in injection moulding. With the IAP1 sprue picker, we provide a cost-effective entry into the world of process automation.The picker reaches sideways into the stripper and ejector tool moulds of injection-moulding machines, eliminating manual work and speeding up the entire process, making production more economical. The picker is especially well suited to automating and retrofitting small injection moulding machines and allows for removal and separation of sprue in very tight spaces.

The sprue picker automates the removal and separation of sprue in the injection-moulding machine.

Contact an expert

How is the sprue picker designed? And what igus® products can be used?

The sprue picker is modular. Our high-performance polymers are used for the moving components - free from lubrication and maintenance.drylin® W linear guides

- 100% lubrication and maintenance-free

- Wear-resistant

- Up to 40% more cost-effective than recirculating ball bearing guides

- Find out more information

Visit the shop

Lead screw nuts and lead screws

- Completely dry operation: up to 2.5 times higher efficiency thanks to optimum flank angle

- Quiet and vibration dampening

- Tested: up to 25 per cent less wear

- Find out more information

Visit the shop

drylin N low-profile linear guides

- 100% free of maintenance and lubrication

- Low wear with low coefficient of friction

- Low profile between 6 and 12mm

- Lightweight

- Find out more information

Visit the shop

iglidur® J plain bearings

- Low coefficient of friction

- Wear-resistant material for continuous operation

- Maintenance-free

- Over 250 sizes available from stock

- Find out more information

Visit the shop

iglidur® J plate bar stock

- Low half value in dry operation

- Maintenance-free and predictable

- Standard range from stock

- Machining with no minimum order quantity

- Find out more information

Visit the shop

Robots

- We have a large range of robots for Sprue pickers:

- delta robots

- linear robots

- Robot arms

- Find out more information

Visit the shop

Advantages of the sprue picker:

- Cost-effective automation on the injection-moulding machine for less than £2,000 (starting price)

- More economical production without manual handling of the sprue

- ROI possible after just a few months

Scope of delivery:

- Sprue picker kinematics IAP1

- Motor control system drylin® dryve D1

- Sample program for EUROMAP/SELOGICA

Economical use in in-house production

We also use our compact sprue picker ourselves in our own production - in more than 330 machines. This means that we can achieve automated separation of sprue and components in just 1.25 seconds.Less than £2,000 entry-level price

100 per cent lubrication-free operation

24/7: designed for continuous operation

Do you need more information?

In our two-part blog series on the sprue picker, we explain what exactly that machine can do, including technical details.

Click here for Part 1 of the blog