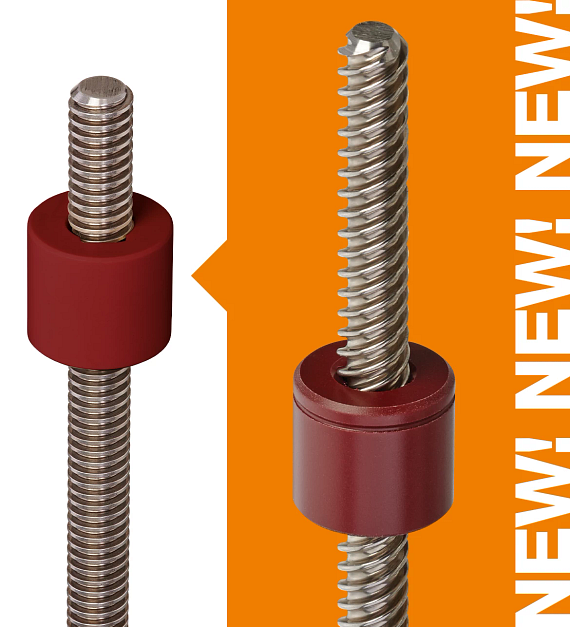

Expansion of dryspin® lead screw nuts

Expansion of the product range of dryspin® lead screw nuts made of bar stock

By three new dimensions

New pitches DS10x20 RH, DS12.7x10 RH and DS25x5 RH: the new dryspin® lead screw nuts made of bar stock in cylindrical, flange or spanner-flat versions.

- Quiet operation due to tighter manufacturing tolerances and rounded tooth geometries by default

- Up to 50.9% more cost-effective than conventional lead screw nuts made of metal

- Up to 25% less wear compared to POM+PTFE (dimension 10x3)

- No lubricating grease or oil in the lead screw drive and long-lasting use thanks to patented asymmetry

- Lead screw drive service life can be calculated online

Discover in the online shop

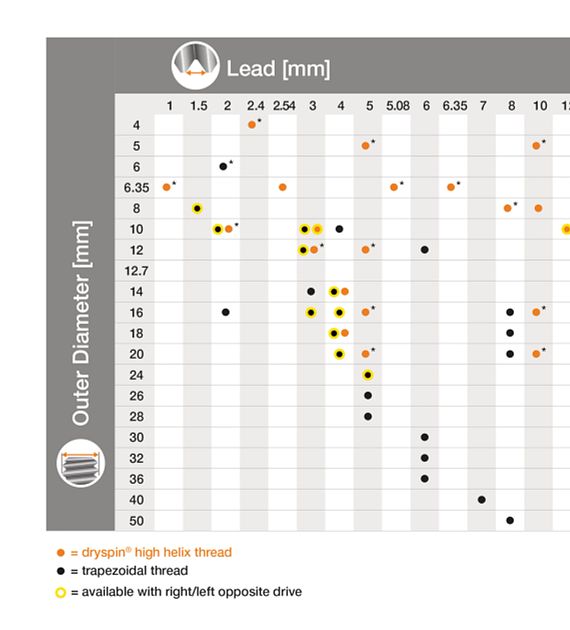

Self-lubricating with high efficiency: Product range [mm]

The new dryspin® lead screw nuts made from bar stock in a cylindrical, flange or spanner flat version with the new pitches DS8x2 RH, DS10x2 LH and DS20x50 LH.| Cylindrical lead screw nuts | DST-□SRM-1812DS10x20 | |||||||||

| Cylindrical lead screw nuts | DST-□SLM-2220DS12.7x10 | |||||||||

| Cylindrical lead screw nuts | DST-□SLM-4540DS25x5 | |||||||||

| Cylindrical lead screw nut with spanner flat | DST-□SLM-172220DS10x20 | |||||||||

| Cylindrical lead screw nut with spanner flat | DST-□SLM-172220DS12.7x10 | |||||||||

| Cylindrical lead screw nut with spanner flat | DST-□SLM-304540DS25x5 | |||||||||

| Flange lead screw nut | DST-□FRM-2020DS10x20 | |||||||||

| Flange lead screw nut | DST-□FLM-2525DS12.7x10 | |||||||||

| Flange lead screw nut | DST-□FLM-3244DS25x5 | |||||||||

| Flange lead screw nut with spanner flat | DST-□FRM-202020DS10x20 | |||||||||

| Flange lead screw nut with spanner flat | DST-□FLM-252525DS12.7x10 | |||||||||

| Flange lead screw nut with spanner flat | DST-□FLM-323244DS25x5 |

The new dimensions of the dryspin® lead screw nuts made of bar stock at a glance

Further important information:

The dimensions of the dryspin® lead screw drives

Everything at a glance and sorted by specifications

Six different types of lead screw nut made of seven different materials with individual specifications are available. Suitable lead screws are available in high helix, trapezoidal and metric threads and in stainless steel, steel and aluminium. We have clearly presented all dimensions for you.

► Diameters from 4 to 50mm and pitches from 0.5 to 100mm

► More than 5,000 variants in the standard product range

► Different materials and types

► Our experts will be happy to help you choose

► Diameters from 4 to 50mm and pitches from 0.5 to 100mm

► More than 5,000 variants in the standard product range

► Different materials and types

► Our experts will be happy to help you choose

Go to dimensions table

Are you looking for the right lead screws?

Here you will find all the necessary information

Of course, we have expanded our dryspin® lead screw product range not only with the new lead screw nuts, but also with the matching lead screws.

The dryspin lead screws offer numerous advantages:

► 100% corrosion-free

► Quiet operation due to rounded tooth geometry

► Up to 30% longer service life due to thread asymmetry

► And many more advantages

The dryspin lead screws offer numerous advantages:

► 100% corrosion-free

► Quiet operation due to rounded tooth geometry

► Up to 30% longer service life due to thread asymmetry

► And many more advantages

Discover the matching lead screws here

The alternative to conventional trapezoidal lead screws

More operating smoothness and less vibrations

The new high helix thread sizes DS10x3 LH, DS14x4, and DS18x4 are perfectly suited as an alternative to the trapezoidal lead screws of the same dimensions.

The dryspin high-helix lead screws offer numerous advantages:

► Quiet and low-vibration operation thanks to rounded teeth

► Longer service life due to asymmetry

► Higher efficiencies through optimised flank angles

► 100% corrosion-free, self-locking and many other advantages

The dryspin high-helix lead screws offer numerous advantages:

► Quiet and low-vibration operation thanks to rounded teeth

► Longer service life due to asymmetry

► Higher efficiencies through optimised flank angles

► 100% corrosion-free, self-locking and many other advantages

Get more information on the alternative to trapezoidal threads

dryspin® thread geometry

Smooth operation, less vibration - THE alternative to trapezoidal threads

What does lead screw technology mean and what do I understand by it?Lead screw technology is a part of drive technology and, roughly speaking, describes the repetitive conversion of a rotary movement into a translatory movement within regular cycles. The dryspin® lead screw technology was patented in 2014 by the dryspin® Lead Screw Technology Development Team. Particular emphasis was placed on increasing service life and improving efficiency. The dryspin® product range includes (high-helix) lead screws made of stainless steel or aluminium and the suitable lead screw nuts made of igus® high-performance polymers. They are available with pitches from 1mm to 100mm. The dryspin® thread geometry is an extension of conventional thread technologies, such as metric and trapezoidal threads. dryspin® lead screw technology has many advantages over conventional lead screw geometries.How can I find out the thread direction of my lead screw?

Whether the direction of a thread rotation is right or left can be easily determined with a visual inspection. If you look at the lead screw from the front, you can best see the difference between left-hand and right-hand threads. For lead screws with right-hand thread, the thread flanks rise from bottom left to top right. In production drawings, right-hand threads are often marked with the letters RH, e.g. DS10x20-RH. More information.

Self-locking - what does that mean?

Self-locking means that lead screw nuts and lead screws cannot be moved without the application of external force. As soon as the static friction is exceeded, the components are no longer self-locking. Multistart trapezoidal screw drives have a "residual self-locking" feature; high helix screw drives have no self-locking feature. Since the self-locking depends both on the pitch angle and on the coefficient of friction of the sliding pair, a loss of self-locking can occur with very low coefficients of friction even with single start trapezoidal threads. More information.

Quiet and vibration-free operation and higher speeds

Due to the rounded tooth flanks and tighter manufacturing tolerances of the dryspin® thread geometry, the possible noise-causing contact surface between the lead screw nut and the lead screw is reduced. The reason for this is that the greater the contact of two surfaces moving against one another, the more vibrations are transmitted, which can be perceived as a rattle or squeak. This means that higher travel speeds can be achieved without causing the corresponding noise.

Up to 30% longer service life - due to thread asymmetry

Due to larger gaps between the individual dryspin® thread pitches, the thread ideally adapts to the specifications of the lubrication-free igus® high-performance polymers. The proportion of the tribologically optimised polymer in the thread pitches can be enhanced by a factor of 1.3. More wear-resistant material and higher levels of efficiency are crucial for a service life that is up to five times longer compared to standard thread geometries. More information.

Can I lubricate my plastic lead screw?

It is no secret that igus® is an advocate of non-lubrication of bearings. Simply put, lubrication is not required for igus® products. Many people think that greasing some products is essential to guarantee that they do not seize up and ensure smooth movement. However, it is easy to forget that lubrication is not a prerequisite for all products. No lubrication is required for igus® lead screw nuts; however, it can still be used. It is essential to check the resistance to the lubricants that will be used.

Try out dryspin® technology for yourself

With the help of the free lead screw sample

Holding a real sample in your hands is an important part of understanding your component. We will be happy to send you a sample of our dryspin lead screw drives for this purpose. We have summarised all the specifications and advantages of dryspin lead screw technology in the sample for you. See for yourself and if you have any questions, our experts will be very happy to help.Request free lead screw sample here