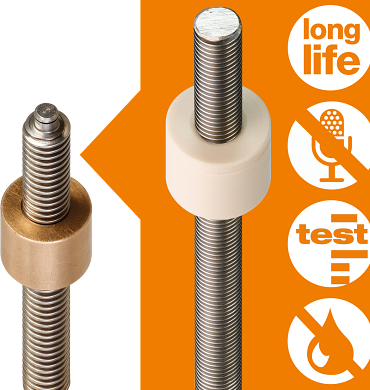

Efficient alternative to trapezoidal threads

We have tested it!

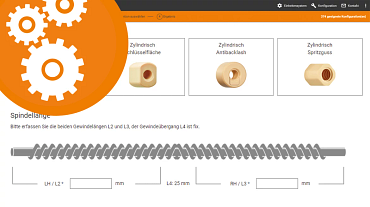

Our dryspin lead screw geometry is an excellent alternative to conventional trapezoidal threads. The wear tests show that the thread dimension with the dryspin® geometry has up to 25% lower wear rate and up to 30% longer service life.But it is not only the longer service life and the low wear rate that are convincing. The specifications and geometries of our lead screw technology matched to the iglidur® plastic nut and lead screw also enable efficiencies of up to 82% and noise- and vibration-free operation compared to trapezoidal threads.Our new dimensions are suitable for 1:1 exchange: DS10x3, DS14x4, DS18x4, DS10x2 and DS12x3. Here you can find more information about your exchange. If you have any questions, our experts will help you.

An overview of the alternative dryspin® thread dimensions to DIN 103

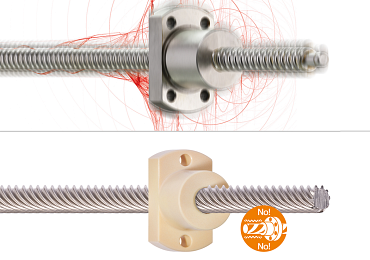

► Greater rigidity

► Higher speeds thanks to dryspin® geometry

► Optimised flank angle

► Quiet, vibration-free operation

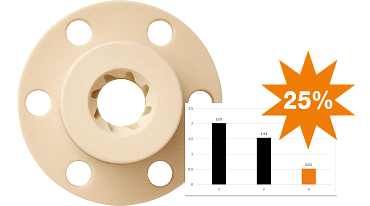

Wear test: new measurement Ds10x3

igus® dimension testing: dryspin® technology beats competitors and trapezoidal threads

Test parameter

Load: 50N

Stroke: 140mm

Speed: 450rpm

Test duration: 150,000 cycles

Y = wear rate [μm/km]

1. Competition's geometry 10x3 / PET + PTFE

2. TR10x3 / AISI 304 iglidur® J / injection moulding

3. DS10x3 / AISI 304 iglidur® J / injection moulding

Test result

The evaluation of the wear test for the product with the dimensions 10x3 made of stainless steel showed that our dryspin® thread Ds10x3 can achieve a wear rate up to 25% lower, a service life up to 25% longer and greater efficiency compared to the competition and the trapezoidal thread Tr10x3.

Benefits of dryspin® technology

Up to 25% less wear

dryspin® technology beats trapezoidal thread and competitors in the test

Our experimental evaluation of the wear test of the 10x3 dimension made of stainless steel shows clear results. The dryspin® high helix thread Ds10x3 achieves up to 25% lower wear rates, up to 30% longer service life and significantly higher efficiencies compared to the trapezoidal thread Tr10x3 and the competition.Noise-free and vibration-free operation

Thanks to the rounded tooth flanks of the dryspin high helix thread geometry

The rounded tooth flanks of the dryspin thread geometry reduce the possible noise-causing contact surface between the lead screw nut and the lead screw. This is due to the fact that the greater the contact of two surfaces moving against one another, the more vibrations are transmitted, which can be perceived as a rattle or squeak. The rounded teeth minimise this effect and the dryspin high helix thread moves vibration-free and virtually noise-free.100% lubrication-free and maintenance-free

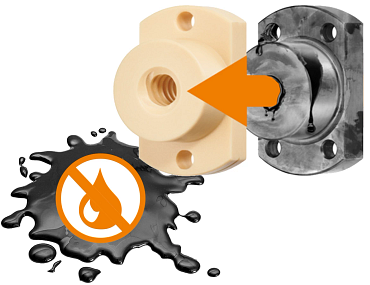

Ideally suited for long-lasting applications

Lubrication is essential for metal lead screw nuts, otherwise metallic abrasion will occur. Without appropriate maintenance the abrasion can block the entire system and the application can break down quickly. The lubrication-free and maintenance-free drylin lead screw drives are the perfect alternative to conventional lead screw drives made of metal. With our drylin lead screw nuts made of iglidur high-performance polymers, you do not need a single drop of lubricant. Self-lubrication reduces maintenance to a minimum. Dry running gives particles such as dust and fibre much less purchase. In dirty environments, this greatly increases service life over that of conventional, lubricated solutions.Up to 30% longer service life

Thanks to thread asymmetry

Due to the larger distances between the individual dryspin® thread turns, the thread ideally matches the specifications of the lubrication-free igus® high performance polymers. The proportion of the tribologically optimised polymer in the thread turns can be enhanced by a factor of 1.3 for all sizes. More wear-resistant material and higher levels of efficiency are crucial for a service life that is up to 5 times longer compared to standard thread geometries.