Ball bearing wiki: Technical information about ball bearings

Our ball bearing wiki at a glance:

What is the structure of a ball bearing?

Inner and outer race:

The suitability of a xiros plastic ball bearing is determined by the materials of the two races. Our low-friction ball bearings are made of high-performance polymers with different material properties, which means that they can be used in many applications and service life can be maximised.Ball bearing cage:

The cages of our plastic ball bearings are perfectly matched to the materials of the outer and inner races in terms of chemical and temperature resistance.Ball bearing balls:

In addition to stainless steel balls, balls made of glass, plastic or ceramic are also used. Glass balls should be selected when 'metal-free' and 'chemical-resistant' are required properties. Plastic balls result in particularly light ball bearings. The stainless steel version is particularly cost-effective and temperature-resistant.Visit the shop

What is a ball bearing?

Without ball bearings, the world wouldn't really turn, would it?Because you simply see the world as it is. Everything grows and develops, is in motion and is taken for granted. However, people hardly ever think about such a marvel of technology: the ball bearing. You encounter it every day in your life, whether you're travelling to work by bike, train, bus or car. Because ball bearings are found in all means of transport, and also in kitchen appliances, training equipment in the gym or at the bowling alley in the evening - we find ball bearings everywhere. But what is a ball bearing anyway? Since the development of the steam engine and the beginning of industrialisation, ball bearings have become indispensable in our everyday lives.

Ball bearings, also known as rolling bearings, are bearing components that reduce the frictional resistance caused by rolling bodies between an inner race and an outer race. They are used to fix axes and shafts and can absorb radial and/or axial forces, depending on the type. Due to their design, they also allow the shaft or other components that are mounted on an axis, such as a wheel, to rotate.

When should I change my ball bearing?

Change ball bearing? This should happen when ...- the bearing clearance caused by wear has reached an unacceptable level, for example when the shaft "slags".

- the cage is worn and threatens to fall out.

- the bearing races are broken due to excessive impact forces.

- the running surfaces of the bearing races are visibly damaged.

- the ball bearing is blocked, for example due to coarse dirt .

- the balls (glass) are broken .

- "unprecedented noise emissions" occur.

- no bearing clearance exists due to deposits on the balls.

If there is a blockage due to coarse contamination, it may be possible to rinse or blow out the ball bearing and it can be used again. This applies if there is no damage to the bearing rings and balls.Each customer defines the wear limit for himself depending on the field of application. For applications that require high precision or positioning accuracy, maintenance intervals should be shorter. For users who, for example, use xiros conveyor rollers, a higher level of acceptance can apply, as only simple guiding tasks need to be performed.Our polymer ball bearings have a radial bearing clearance of approx. 0.05 to 0.15mm. They owe this characteristic to their smooth running and low breakaway torque. The open design also makes them very easy to clean.

Is it really necessary to lubricate ball bearings?

Metal ball bearings are generally dependent on lubricants. But is it possible to avoid it? Our plastic ball bearings are an example of how it can be avoided.Read more in our blog

In-house test laboratory for plastic ball bearings

Our ball bearings are put through their paces. Years of research in our test laboratory have resulted in numerous product advantages for our xiros plastic ball bearings compared to their metallic counterparts. The expertise gained flows into further developments and new products that are ideally suited to the most individual applications.Find out more about the test lab

How do I mount ball bearings?

If metal ball bearings are fixed or floating bearings, the outer and/or inner races are firmly connected to the shaft or housing. The easiest way to attach this type of bearing is to press-fit into place. However, certain tolerances are necessary in the dimensions for the shaft and housing. In general, it can be assumed that the rotating ring is executed in the firm fit, a so-called interference fit, and the stationary ring is made in the loose fit, the clearance fit up to transition fit. If there is an impact on the bearing, both the rotating and stationary ring will be executed in a firm fit. Easy assembly and disassembly of the bearing and preventing the ring from spinning is essential. Furthermore, the inner race can also be pressed with a clamping sleeve or clamped between a nut or clamping screw.In the thermal process, or also known as heat shrinking, the metal ball bearing is usually heated to a temperature of up to 125°C by induction. As a result, the entire bearing expands and can be pushed onto the cold shaft without any problems. After the ball bearing has cooled down, it contracts resulting in an extremely tight fit on the shaft.

But how do you attach/install and measure the xiros plastic ball bearings? We are one of the few manufacturers in the world to produce ball bearing races by injection moulding. This offers users the following advantages:

- High wear resistance due to the shape under high pressure

- Homogeneous material distribution

- Cost-effective production meaning economical prices

- Simplification of ball bearing installation

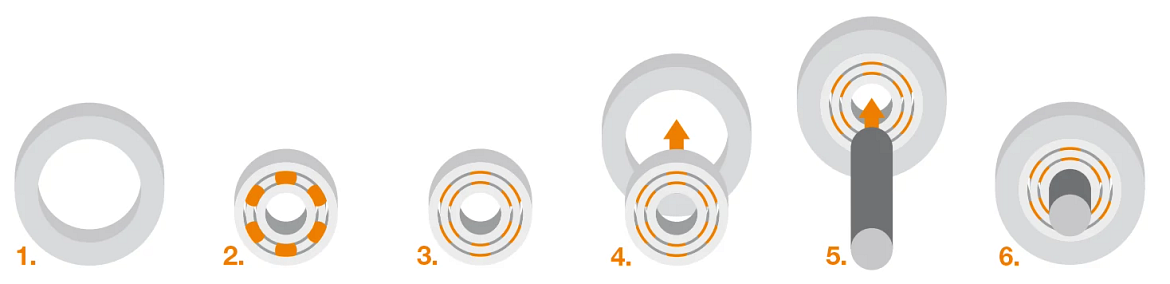

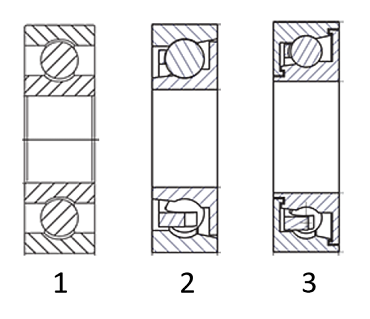

1. Housing (tolerance H7)

2. Front side (balls visible)

3. Rear side (cage visible)

4. Press-fit the ball bearing with the front side first

5. Install shaft (tolerance h6) with chamfer

6. Locating spigot must be provided

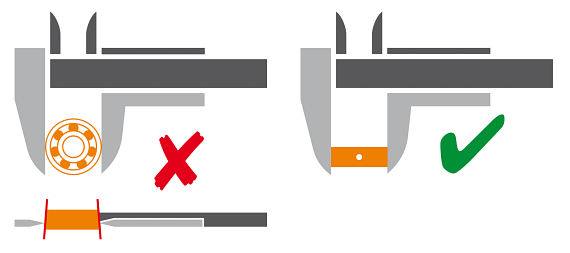

Measuring ball bearings: tolerances and measurement recommendation

The tolerances for inner and outer diameters depend on the installation size. These are often approx. ±0.05mm to the nominal dimension. The bearing races are usually injection moulded and have a certain ovality by nature. For this reason, the caliper is used to measure 90° to the injection point (if present) across the entire width of the bearing. The dimensions and tolerances are designed in such a way that they fulfil a light press fit by hand when using a holder H7 and shaft h6. Additional locating spigot by means of a locking ring (shaft) and snap ring (housing) is recommended to prevent axial displacement.What ball bearing seals are available? Ball bearing open or closed?

Many metallic rolling bearings are available as a sealed version. Ball bearing seals are generally essential for the metallic version, as otherwise contamination can combine with the lubricant and thus block the running of the bearing. Should the ball bearing be open or closed? This depends on the type of ball bearing.

The sealing of metallic ball bearings is based on the principle of the shaft seal. These seal designations are possible:

Metallic bearings must be protected

Metallic ball bearings are also available in open type. However, these are rarely used due to the problems mentioned above. Therefore, a dusty environment is sufficient to negatively influence the running performance over a longer period of time.The sealing of metallic ball bearings is based on the principle of the shaft seal. These seal designations are possible:

- Z = one-sided sheet metal cover disc with gap seal

- ZZ/2Z = as above, from both sides

- RS = one-sided, grinding rubber seal

- LB = as above

- 2RS = as above, from both sides

- LLU = as above, non-contact rubber seal, from both sides

- EE = as above, touching from both sides, grinding

- RZ = one-sided, non-contact rubber seal

- LB = as above

- 2RZ = as above, from both sides

- LLB = as above

Plastic or ceramic ball bearings: open or closed?

These two ball bearing types are usually only available as open type. The reason for this is that these bearings need not be lubricated. The open construction has a great advantage with these materials. Any dirt that gets in can also easily come out again, or be rinsed or blown out with compressed air. This prevents dirt adhesion due to lubricants. igus therefore dispenses with the use of suffixes compared to the metallic counterpart.Browse the online shop now

xiros plastic ball bearing with cover disc

In our online shop, customers can choose between different cover variants. Not all are available for every bearing installation size, but a one-sided cover plate is always available for selection.

- Open design

- Single-sided cover disc

- labyrinth seal on both sides

How do the balls get into the ball bearing?

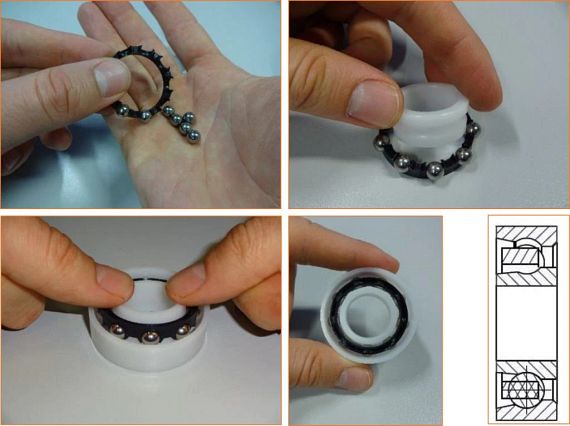

Ball bearings consist of an inner and outer race, a cage and rolling elements. The cage is used to separate the rolling elements from each other in the form of balls. If the balls were not separated, they would run against each other and overheat. This would result in destructive effects at high rotational speeds and ball friction. But how do the balls get into the ball bearing?Possibility 1:

When looking at a grooved ball bearing according to DIN 625, this question is easy to answer, as these have noticeable indentations on the inner and outer race. If the inner and outer races are displaced to the respective indentations, the balls can easily be filled into the running grooves and secured with the cage. Here the cage takes over the function of keeping the balls from falling out.Option 2:

Heating the outer race and cooling the inner race is also unusual, but is practised in the industry for smaller metal bearings down to miniature designs. The balls and cages can then be easily inserted into the space created between the inner and outer race. If the materials of the races contract or expand again, the ball bearing has reached its standard dimensions and all balls are in place. For igus, only the first possibility can be considered, but there are others that are illustrated below.

How the balls get into the ball bearing at igus: