Exclusive preview

Safe format adjustment in inspection technology at Krones AG

Linear axes, plain bearings, slewing ring bearings, e-chains and gearbox solutions for modern testing systems

Quality management is becoming increasingly important in the beverage industry and corresponding systems are also becoming increasingly modern. In modern testing technology, however, many movements are also carried out, such as when making format adjustments, or when aligning products that require reliable linear axes, plain bearings, gearboxes or even e-chains for cable guidance. In this user report, you can find out which igus products are hidden in Krones AG's inspection technology.Profile

- What was needed: drylin SLW-1660 and SLW-25120, iglidur plain bearings Slewing ring bearings, dryspin nuts, robolink Apiro joint, E2-mini type e-chains

- Requirements: Hygienic design, freedom from lubrication and maintenance, safe and reliable operation

- Industry: Inspection technology; beverage industry

- Success for the customer: iglidur materials in plain bearings and the sliding elements of linear axes are maintenance-free and lubrication-free and significantly increase maintenance intervals in Krones testing systems.

Problem

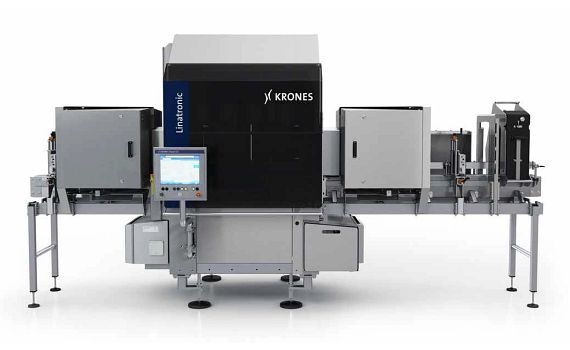

Inspection technology is becoming increasingly important in the beverage industry. On the one hand, it maintains quality standards and, on the other hand, it represents a cornerstone for modern reusable concepts.Plant manufacturer Krones therefore also offers testing systems for empty containers as well as filled bottles. In the former case, the Linatronic 735 is used, for example, which ejects foreign bottles before refilling and checks the remaining bottles, e.g. for contamination or breakage.

After filling, bottles are checked for the fill level, correct sealing or labelling, for example. In all of these cases, it is not only necessary to adjust the system to different bottle sizes, but several camera systems are also used, which must also be handled reliably.

Solution

To enable the testing of various formats when inspecting empty bottles, Krones uses dryspin TR16x2 nuts for its Linatronic. In the subsequent removal system for unwanted bottles, iglidur plain bearings and a drylin SLW-1660 linear system for format adjustment are used.Moreover, maintenance is also simplified with motion plastics. In order to open the test system, the previously used hinges were replaced with iglidur PRT-01-50 slewing ring bearings for maintenance-free and lubrication-free bearing arrangement: an important contribution to hygienic design.

And even when inspecting the products that have already been filled, the plant manufacturer relies on the torsion-resistant aluminium double-shaft profiles of the SLW series for format adjustment. For example, cameras are adjusted using drylin SLW-1660 and SLW-25120 linear axes to check filling and sealing. The camera technology cables are moved safely using E2-mini type e-chains.

A robolink Apiro joint RL-A9.0108 and a dryspin trapezoidal lead screw nut ensure that the bottles are aligned before labelling.