Slewing ring bearings

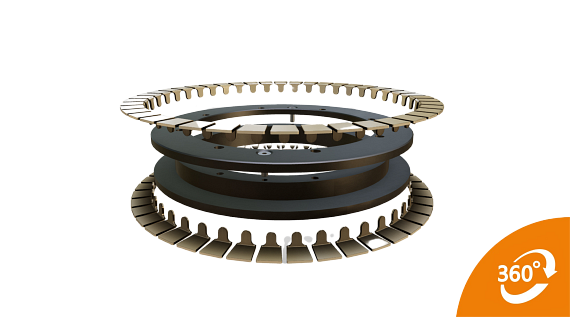

Slewing ring bearings are ready-to-install slewing rings for lubrication-free, dry operations. The design is not based on metal rollers or balls but on maintenance-free sliding elements made of the proven tribologically optimised iglidur® materials.

This is in combination with rings made of lightweight anodised aluminium or stainless steel. iglidur® materials can be employed universally and enable use in applications involving high temperatures, moisture or contact with chemicals, as well as in the food industry.

PRT slewing ring options

iglidur® slewing ring, PRT-01

- For very high loads and high rigidity

- Completely maintenance-free

- Easy to install and replaceable sliding pads

iglidur® slewing ring, PRT-02

- Extremely light weight slewing ring

- Head rings made from iglidur® J4

- For very high loads and high rigidity

iglidur® slewing ring, PRT-04

- Even more compact design possible

- For high loads, high stiffness

- Simple assembly, replaceable sliding elements

PRT toothed outer ring

- 4 standards for the toothing of the outer ring

- Easy to install and replaceable sliding pads

- Body and toothed outer ring made of aluminium

xiros® slewing ring ball bearing

- Chemically resistant

- Low humidity absorption

- Cage material: xirodur B180

PRT stainless steel housing

- ESD compliant

- Replaceable sliding elements made of iglidur® F2

- Stainless steel housing

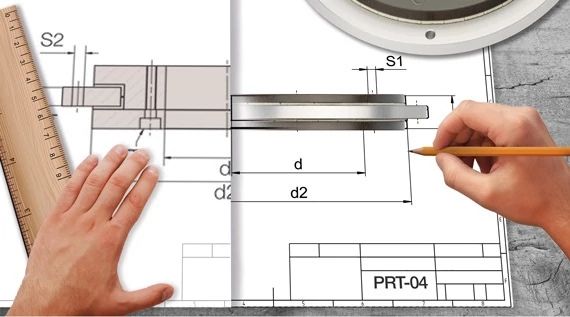

PRT special parts

- Does a standard PRT now quite fit?

- We can make you a bespoke version to suit your requirements.

Configure your PRT slewing ring system

The slewing ring configurator will enable you to discover the most suited slewing ring for your application. With just a few simple steps, the expert system can decipher which PRT slewing ring is suitable and can calculate the expected service life. If you need help with the configuration tool please visit our blog for step-by-step instructions.

Slewing Ring Applications

The benefits of slewing ring systems

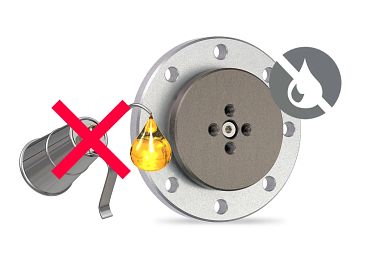

- 100% maintenance-free and lubrication-free

- Corrosion-resistant and hygienic

- Resistant to dirt, dust and humidity

- Cost-effective

Slewing Ring Applications

The benefits of slewing ring systems

- Very slim design

- Robust

- Ready-to-install & easy to assemble

- Individually configurable

Frequently asked questions about slewing ring systems

What is a slewing ring?

A slewing ring is a rotational bearing which can be used to support oscillating movements within applications.

How does a slewing ring work?

The slewing ring consists of two concentric rings, one of which is attached to a rotating object and the other to a stationary surface. The bearing can the move rotationally whilst staying fixed to the mounting surface.

How to change a slew ring

It depends on the slewing ring to be honest. There are variations with metal components, plastic, ball bearings and each variant needs to be considered differently. For igus® slewing rings it is easy. If it is the wear parts of the slewing ring that needs changing, simply remove the screws to take the top part of the bearing off, remove the worn section of the liner and replace with a new section of liner. Quick and easy.

Can I restrict the rotation of my slewing ring?

Yes, igus® have a couple of ways in which this can be achieved to any number of degrees. Our Angle limiter kit comprises of the limiter, a limiter stop and pin which all work externally and can be adjusted by yourself. This can be readjusted should the degree of rotation change for your application.

Advantages of the iglidur® PRT slewing ring bearings

Cost-effective

Manufacturing with injection moulding or 3D printing guarantees cost efficiency and creates the geometrical freedom to optimise use of installation space. Thanks to the flexible modular system, the slewing ring ball bearings can be extended as required.

Lubrication and maintenance-free

Up to 60% lighter

The iglidur® bearing technology impresses with ultra-light materials, such as plastic and aluminium. This enables you to achieve greater efficiency in your application.

Quiet dry operation

The igus® PRT slewing ring bearings with plastic sliding elements produce significantly less noise and vibrations. For you as an operator, plastic gears - for example in robots - lead to an application that is up to four times quieter.

Resistant to chemicals and media

Suitable for the food industry (FDA) and for daily cleaning with cleaning agents and high pressure. PRT slewing ring bearings are also an ideal solution for special applications with high temperatures of up to 180°C or ESD.

The rings are made of plastic, aluminium or stainless steel.

Tested and proven

Interactive 3D models

CAD files