Energy chains and cables for long

travels in shipyards

Shipyard cranes are mostly huge systems that can lift huge lifting loads and must always work reliably. At the same time, the space available in the shipyards is usually very tight. The requirements for cable guidance therefore lie in systems that are as space-optimised and at the same time powerful as possible, which safely master long travels.

In order to achieve this top performance, we offer a comprehensive portfolio of energy chains, cables, guide troughs and complementary accessories.

In order to achieve this top performance, we offer a comprehensive portfolio of energy chains, cables, guide troughs and complementary accessories.

Successful application stories with shipyard cranes

Energy chains for large ship production

At Meyer Werft GmbH in Papenburg, modern plastic energy supply systems are used to supply energy and media to a gigantic crane system with a total of eight crane bridges.Learn more about this application

... and other success stories

In other application examples, discover how our energy chains and chainflex cables are used in the crane industry for different requirements.Discover further success stories

System comparison

Energy chain systems instead of festooning, motor cable drums and busbars

Provide guidance for cables and energy chains while keeping them protected and safe in wind and fluctuating temperatures. This minimises downtime.

More about the festooning alternative

No slip ring on long travels. Guide all media safely in one system. Travels of up to 1,000 metres.

More about the motor cable drum alternative

Deliver data, energy, fluids and air safely in a single energy chain system. For narrow compact spaces and fast lane movement.

More about the busbar system alternative

Durable products for crane technology

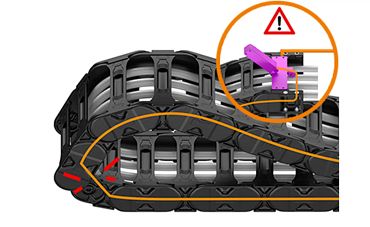

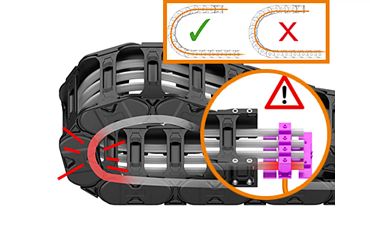

Roller energy chains

- High push/pull forces and less wear thanks to precise tolerances.

- Maintenance-free rollers reduce push/pull forces of up to 75% and allow very long travels

Find out more about roller e-chains

Guide troughs

- Available in stainless steel and aluminium for seawater resistance and weight reduction

- Also available as a cost-effective and corrosion-free plastic trough

Find out more about guide troughs

Floating moving end

- As compensation in the case of long travels

- Small, lightweight and cost-effective

- Compatible with isense EC.P

- Can be deployed with a range of energy supplies

Find out more about floating moving ends

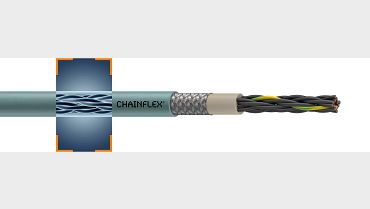

chainflex for moving applications

- Cables for use in energy chains

- Wide range of products

- Designed for enormous speeds and accelerations, long travels and the most adverse environmental influences

Learn more about chainflex cables

Motor cables

- Mostly with TPE outer jacket material for extreme temperature ranges

- High abrasion resistance for a long service life

- Service life predictable online. With a four-year guarantee

Find out more about our motor cables

Control cables

- From 12 cores with cores wound in bundles

- Long operating times thanks to the avoidance of corkscrews

- Service life predictable online. With a four-year guarantee

Learn more about our control cables

Pull/push force detection (EC.P) for energy chains

Suitable for every type of crane and every energy chain. The EC.P sensor technology continuously measures the forces generated on the e-chain and thus prevents unplanned failures. Before surprises arise, a recommendation is made to shut down the system if the forces are too high.Further information

Intelligent break detection (EC.B) for energy chains

For energy chains that carry high loads during continuous use, the installation of sensors is suitable for early breakage detection. If a chain link break occurs, this is detected immediately and an alarm is triggered. Consequential damage up to complete system failure can be avoided.Further information

Monitoring of cable tensile force (CF.P) with the aid of cables

With CF.P sensors on your energy chain, the load on the cables can be monitored in real time. For this purpose, the system is attached to the strain relief. If a critical set value is exceeded, an alarm or system shutdown can be triggered if required.Further information

.jpg?color=ececec&crop=no&w=370&quality=80)