The alternative to cable festoon systems: energy chain systems

With festoon systems, the cables hang unprotected on cranes in wind and weather. The cables themselves and the festoon systems are exposed to varying temperatures as well as sand and salt (at outdoor facilities). The wind often lets the cables get tangled, which quickly results in downtime. igus offers a reliable and modular alternative to festoon systems on cranes, which helps you save cable length and avoid downtime. Energy, data, fibre optics, oil and air are safely managed in one system. More than 1,300 STS and over 6,500 RTG/RMG ASC cranes have been fitted with energy chains.

Would you like more information about our energy chains? Our experts will be happy to get in touch with you.

Would you like more information about our energy chains? Our experts will be happy to get in touch with you.

Contact an expert

What is the difference between energy chain systems and cable festoon systems?

We have compared energy chain systems and festoon systems at a 100m plant:

Energy chain systems

In the solution with energy chains, the cables are fed into the e-chain in the middle of the travel. The e-chain is pushed or pulled halfway.

Cable lengths/space requirements

- About 50% less cable (52m cable length with centre-fixed installations and approx. 100m travel)

- Approx. 800mm system height

- About 10% less structural steel (for the cable festoon)

Influencing the crane girder construction

No cable station required

Dynamic parameters

Rolling energy chains can be operated at a speed of over 600m/min and with an acceleration of over 2m/sec2 .

Secure cable guidance

Cables are safely guided in the energy chain and cannot get caught anywhere.

Cable festoon systems

In a festoon system, the cables are attached at the end of the travel and the cable loops are pulled all the way by the trolley.

Cable lengths/space requirements

- Approx. 115m cable (115% travel length) for 100m travel

- About 3,500mm length for the "cable loops", system height approx. 5,000mm

Influence on the crane girder construction

Cable festoon is required

Dynamic parameters

Festoon systems reach their limits at speeds of 240m/min. and accelerations of more than 0.8m/sec.2

Secure cable guidance

Cables hang uncontrollably and may get caught in the crane structure (e.g. by wind).

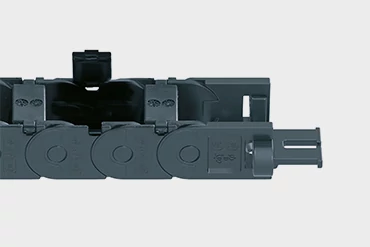

Energy chain systems recommended by us

System 4040HD/5050HD

Find out more

P4.1 system

Find out more

Predictive maintenance

Find out more

White paper: efficient energy supply systems for cranes in steel plants

Plastic energy chains compared to festoon systems

In this white paper, you can find the following topics:

- Advantages and disadvantages of energy chain systems and festoon systems for steelworks cranes

- The most innovative solution for cranes for steel plants

- Future technologies: roller energy chains

Download now

Related products

readychain®

Find out more

energy chains

Find out more

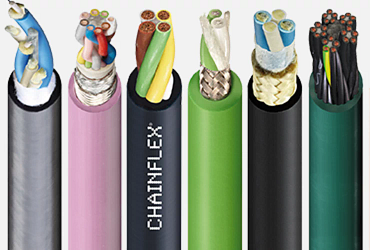

chainflex®

Find out more

For maximum service life with optimised design - P4HD.56R heavy-duty rol e-chain

The new heavy-duty rol e-chain meets all the relevant requirements for container cranes of the next and future generations.Longer and longer travels, greater dynamics, short stress cycles, zero failures: in brief, this is what is demanded by the manufacturers of ship-to-shore container cranes for energy chains on the crane bridges. The new P4HD.56R fulfils these requirements - with maximum economy.Ask for a free sample now

Selected application examples

Bulk handling crane with durable energy chain

On 441 metres travel with a max. acceleration of 01m/sec², a motor cable drum and thus slip rings were used for the main power and data supply. Due to the high maintenance requirements, the operator opted for a new roller energy chain and fail-safe chainflex cables. This arrangement is not only simpler, safer and more secure than the motorised cable drum previously used, it also facilitates the supply of data via fibre optic cables.

Go to complete user report

Customised solution for STS cranes

This STS application is exposed to strong wind and consequently requires an energy supply that reliably withstands such conditions. For the customer, it was important that the cables were safely and securely guided in a controlled manner at all times, despite the double boom pivot point. igus designed and tested a customised solution that was subsequently installed together with the crane manufacturer: now, a P4 energy supply and a range of chainflex cables from igus are in use; these guide cables at a speed of up to 240m/min. over a travel of 117 metres.

More than 10 years of trouble-free use

With this RTG crane, the e-chain system from igus has been working trouble-free for more than 10 years, without even one component of the energy chain having to be replaced. With a travel of 19.2m and a speed of 70m/min and an acceleration of 0.7m/sec², the system keeps its promises: reliable cable guidance. The energy chain guides a range of chainflex cables which were developed specifically for moving applications.