Intelligent energy chains & smart cables

Sensors for e-chains®

EC.W

Sensor for energy chain abrasion

- Measures wear at crossbar, pin/bore connection, or liner, depending on design

- Compares specified algorithms with the real use data

- Can also be used as a stand-alone sensor

i.Sense EC.W service life sensor

EC.PP

Sensor for position-sensitive push/pull force measurement

- Positioning system integrated into e-chain

- Supplies information on position-dependent push/pull forces

- Position information from the application can be used for other purposes

EC.M

Sensor for movement on e-chains

- Detects values such as acceleration, speed, temperature and cycles

- Supplies data for calculation of the minimum fault-free operating time

EC.I

Non-contact measurement of e-chain wear

- Integrated in the chain link, the component subjected to the greatest mechanical stress

- Measures the wear of pin/bore connection in per cent, without contact occurring

- Sends a signal if the specified limit is reached

smart plastics news 2023 ...

... experience now all smart plastics 2023 new products like the breakage monitoring for robot chains i.Sense TR.B or for the first time the new smart all-round service superwise right here:Industry 4.0: 2023 smart plastics News - overview

"What should I consider with respect to maintenance when selecting e-chains®?"

10 tips for a "maintenance-friendly" energy chain

What this means in concrete terms and what designers should bear in mind - this small guidebook will provide you with numerous practical tips and tricks.

For free PDF download

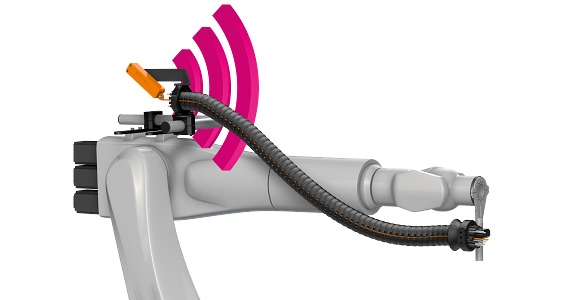

Smart e-chains®

Finally also for multi-axis and industrial robots ...

... i.Sense TR.B for intelligent breakage monitoring

Robots have long been indispensable in many areas of industrial manufacturing – bb welding, painting, soldering, and palletising: industrial robots are becoming dynamic. A flexible 3D energy chain such as the triflex® R from igus® makes it possible to guide robot cables safely. To detect potential chain breaks due to extreme loads in good time and avoid unplanned machine breakdowns, igus has developed i.Sense TR.B, the world's first breakage monitoring system for 3D energy chains.Find out more

P4.1 rol e-chain®

- Longer service life due to maintenance-free tribo-polymer plain bearings in conjunction with the chain links

- For the heaviest duty applications and longest service life

- Travel distance up to 800m and speed higher than 5m/s

- Use smart plastics to stay abreast of how your chain is doing

Find out more

E4 chain series for heavy loads

- Gliding, unsupported, and suspended applications possible

- For robust, challenging areas of use

- Inner height from 21 to 350mm

- Each link consists of four individual parts

- Openable along inner and outer radius

Find out more

E2 chains for medium loads

- Inner height: 26 - 48mm

- Available in two versions:

- Openable from both sides along the outer radius

- Openable from both sides along the inner radius

- Weight to dimension ratio improved on comparable predecessor series

- Can be assembled up to 55% quicker than predecessor

To the E2 chains

3D CAD portal for smart plastics

Design intelligent energy chain systems faster. CAD models for all smart components.

Our intelligent e-chain systems are already reliably in use in hundreds of thousands of applications worldwide - from beverage machines and CNC machines to steel mills. Unsupported lengths can be bridged without problems and long travels are conceivable for the most varied of industries.To the 3D CAD portal

360° insight into the igus test laboratory

All smart plastics test setups can be found here by rotating the mouse across the screen.Smart solutions with chainflex® cables

Condition monitoring (i.Sense) with chainflex® cables requires no additional module.

The system can be integrated and networked without additional software.

In these cases, cables have three options for condition monitoring.

The system can be integrated and networked without additional software.

In these cases, cables have three options for condition monitoring.

- Cable push/pull force measurement (CF.P)

- Cable electrical property measurement (CF.Q)

- Transmission quality measurement (CF.D)

Sensors for chainflex® cables

CF.P

- Condition monitoring

- measures pull forces acting on cables

- If there is a fault, the contact closes, and a notification is sent to the machine

Find out more

CF.Q

- Condition monitoring

- Indicates changes in the electrical properties

- If event of a fault, information about contact and notification to the machine

Find out more

CF.D

- Condition monitoring

- Integrated in the cable, no extra measuring cable necessary

- Package losses are detected in good time

- Alarm via LED, NC contact or the network

Find out more

Do you want to put together your own smart plastics package?

Then download the digital version of our smart plastics Domino now and put together your very own configuration.Afterwards, you can look forward to a playful treat from smart plastics.

Arrange a personal visit

Download smart plastics Domino (PDF)