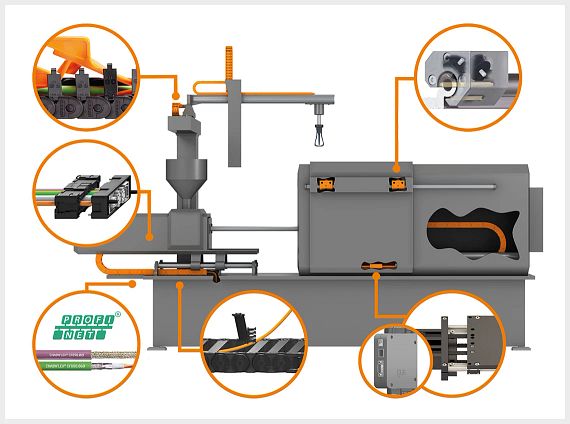

Energy supply systems and bearings for injection moulding machines

The special design of our chainflex cables with strain-relieving core, cores wound in bundles and PVC or TPE outer jackets is ideal for highly dynamic applications, such as the clamping unit with frequent movements and short cycle times. Our e-chains ensure the safe guidance of cable packages. Their design is characterised by simple, fast assembly and a cable-friendly interior - particularly interesting when using hydraulic hoses. In addition to small dimensions for small installation spaces, large unsupported lengths and fill weights; are also possible. Our bearing products made of a wide range of materials score points with lightweight, freedom from corrosion and lubrication, as do drylin linear guides, which, for example, ensure clean sliding of safety doors of the clamping unit.

Products for use in injection moulding machines

Quiet e-chain in picker unit

The standard for applications in the medium-load range

Quiet operation due to integrated brake

Optional opener tool for even quicker opening and closing

Made to measure

ONE interface instead of many plug-in/disconnect points

Simple modular principle, individually configurable

Various possible uses, over 100 inserts to choose from

Maintenance-free hybrid roller bearings

Combination of lubrication-free roll and slide

For minimal drive forces and smooth operation

Low-profile

e-chain with minimum assembly time

High tensile forces, high loads and travels of more than 600m possible

10,000km and more guaranteed running performance

Can be opened and filled quickly

PROFINET cables

A service life of up to 10 million double strokes for bus cables

Four-year functional guarantee

Available unharnessed or harnessed

Toothed belt axes from the modular kit

Compact tandem toothed belt axis with two toothed belts in one unit

Carriages can be controlled synchronously or separately

Fast bearings replacement possible directly on the rail

Cost-effective motor control systems

For DC, EC and stepper motors

Compatible with many industrial control systems

Use with PC, tablet or smart phone

Predictive chain maintenance

Intelligent software and sensor technology on the e-chain

Possible maintenance needs are reported before failure occurs

Advantages of polymer e-chains

High fill weights, accuracy and high temperatures are important factors in energy supply to plastics machines. Our plastic energy chains ensure safe guidance of cables and hoses and also play out their advantages in heavy filling operations:- High fill weights possible

- Circular and pivoting movements possible

- Use in high temperatures

- Resistant to dust, powder deposits and moisture

- Space-saving design

Successfully in use