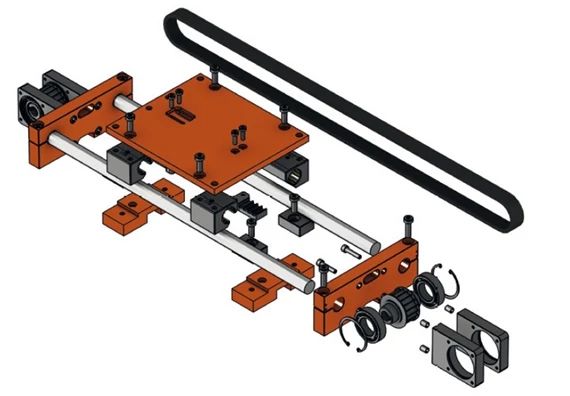

Toothed belt axes from the modular kit

Our toothed belt axes of installation sizes 10 and 20 are based on the open drylin® W modular system and, thanks to the modularity, are flexibly adjustable in width. The innovative exchange bearings of the drylin® W range enable the quick change of the linear liners directly on the rail. The carriage need not be dismantled and the replacement takes place in just a few simple steps.

The benefits at a glance:

- Modular kit system in 3 widths (120/160/200mm)

- Long service life thanks to liners made of iglidur J200 material

ZLW options

ZLW modular axis, Installation Size 10

ZLW modular axis, Installation Size 20

ZLW modular axle, tandem carriage option

ZLW modular axis, Installation Size 10

ZLW modular axis, Installation Size 20

ZLW modular axis, hygienic design option

The hygienic design ensure clean, hygienic operation. The toothed belt and all bearing points are manufactured with FDA-compliant material.

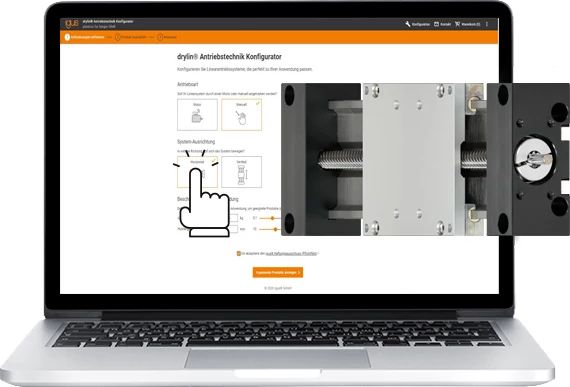

In just a few steps to the harnessed drive system

With the online configurator for the drive technology you will receive the suitable drive technology system based on your requirements. You also have the option of requesting or ordering both motors and other accessories, such as the motor control system.- Fast and easy configuration

- Optional accessories

- Detailed parts list

- Fast delivery

Stainless steel bearing for quick bearing replacement in extreme environments

drylin® W exchange bearing now available in stainless steel

igus® develops and tests materials for drylin® linear technology in its in-house test laboratory, always with the aim of durability, low wear rates, and a predictable service life. But an increasing focus is on this question: "What happens when a bearing has to be replaced?"

- Fast bearing change without disassembly

- Reduced downtime

- Complete re-use of all components

- Simple spare parts management

Liners for a large number of applications

Suitable for your drylin® R linear system

Find the suitable plain bearing liner for your application need. Whether for high speeds or temperatures from -50°C to +250°C, or with FDA/EU conformity. igus® offers the ideal material for your drylin R linear application.

- Low coefficient of friction

- Optimised wear quality

- 100% lubrication-free

- Extremely lightweight

- Chemical-resistant

Motors for lead screw axes

Configure your custom linear system online

- Customise your drive system in just a few steps

- Optional configuration of an individual drive pin

- Automatic generation of a 3D model of the linear system

- Export of the linear system in many different 2D and 3D formats

- 2D dimensional drawing of the module as a PDF

- Download parts list as PDF file

- Add to shopping cart and submit order or request a quotation online