What are hydrodynamic and hydrostatic bearings?

Even if iglidur plain bearings have been developed for lubrication-free applications, they can of course be used with additional lubricants - for example, in hydrodynamic and hydrostatic plain bearings. Find out here exactly how these two types of plain bearing work, what advantages they have and where they are used.

How hydrodynamic plain bearings work

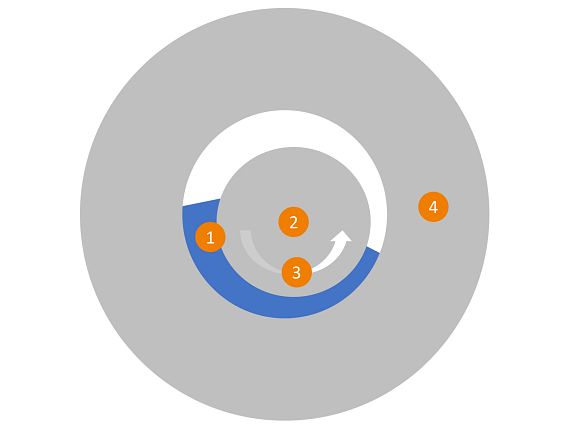

A hydrodynamic plain bearing is a type of bearing in which there is minimal clearance between bearing and shaft. This gap is filled with lubricant. When not in use, the shaft rests on the plain bearing.

When the shaft starts to rotate, lubricant is drawn into the narrow space between the bearing and shaft and the pressure in the lubricant increases the faster the shaft rotates. This forms a so-called lubrication wedge underneath the shaft, lifting it up. As a result, plain bearing and shaft are no longer touching as they are separated by a lubricating film.

Advantages of hydrodynamic bearing positions

- Hydrodynamic lubrication allows for wear-free continuous operation

- Ideal for great bearing forces and diameters as well as high speeds

- Oil film has dampening effect

- Easy installation

This is where hydrodynamic plain bearings are used

Hydrodynamic plain bearings are frequently found in the automotive industry , where they are used in thermal management. They are also common in ships and submarine turbines as they operate with optimum performance in humid environments. They also play an important role in energy generation, especially in wind turbines and hydroelectric power stations. Hydrodynamic plain bearings are also used in industrial machinery, such as large machine tools and pumps. Their ability to carry high loads with low friction makes them ideal for these applications.

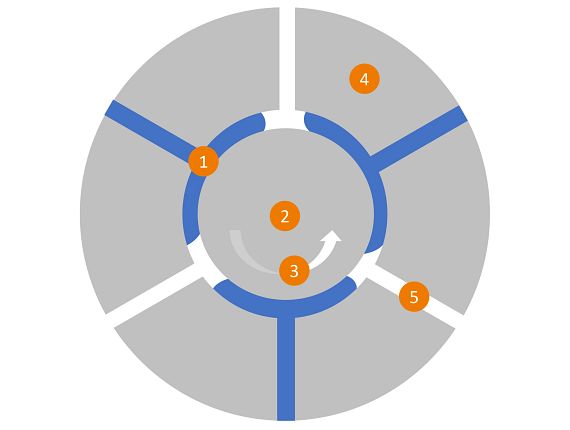

How hydrostatic plain bearings work

A hydrostatic plain bearing is a type of bearing in which a pump is used to insert lubricant between the shaft and the bearing. In contrast to hydrodynamic bearing positions, this type is therefore permanently fully lubricated.

Hydrostatic plain bearings are used when a centric operation of the shaft is required. However, as the oil supply or oil pressure poses a safety risk, hydrodynamic bearings are generally favoured.

Advantages of hydrostatic bearing positions

- The lasting oil film means there is no sliding resistance when starting and stopping

- Low wear of the bearing position

- Low frictional power

This is where hydrostatic plain bearings are used

Hydrostatic plain bearings have areas of application similar to those of hydrodynamic plain bearings. However, as they have a higher true-running accuracy, they are often found in high-precision applications, such as measuring machines or machine tools. Just like hydrodynamic plain bearings, they are also used in power generation. Here, they form part of turbines and generators, among other things.

Our plain bearings for hydrodynamic application areas

igus® offers various plastic bearings that can be combined with hydrodynamic lubrication. Their main differences are the application parameters, such as temperature or chemical resistance, for which they have been developed.

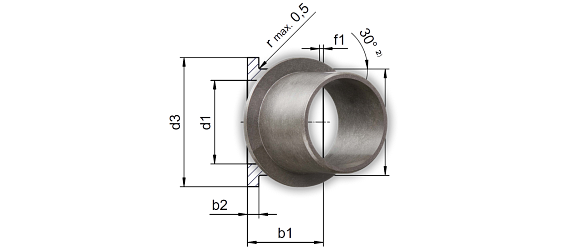

iglidur® UW

- Ideal for underwater (UW) applications

- Extremely wear-resistant

- First choice for pumping applications

- Available as flange and sleeve

iglidur® UW160

- Developed for maximum wear resistance during continuous operation in media

- Suitable for contact with drinking water (KTW-compliant)

iglidur® UW500

- Suitable for underwater applications with temperatures of up to+250°C

- For lubricated use in chemicals

More designs and materials

- Various plain bearing types

- More than 10,000 types

- Service life calculation in real time

Free iglidur plain bearings sample box

See for yourself the quality of our products. The iglidur improves sample box contains:

✅ 39 iglidur plain bearings made from the most important materials✅ Templates for finding the perfect material for your application

✅ iglidur bearing technology catalogue with information about our plain bearings

More plain bearing expertise in our wiki

Here, we have prepared various plain-bearing technology topics for you and answer questions about plain bearings. You will also find a collection of plain bearing white papers that you can download for free.