Plastic gearbox:

reliable & maintenance-free

The gearbox technology

Gearboxes are used to adapt the speed and torque of motors so that they are suitable for the specific requirements of machines and processes.Our drygear® gearboxes made of high-performance plastic: lubrication-free, lightweight and impact-resistant

All igus® plastic gearboxes are modular; they can be extended as required and integrated into existing systems. The drygear® gearboxes are especially popular for robot arms used in quality control or sorting. Gearboxes also come into play with rotary axes or sliding applications, pusher applications or format adjustments.Our gearboxes are the ideal solution for various automation processes.

Discover the range of our gearbox solutions

Versatile and flexible applications with modular gearboxes

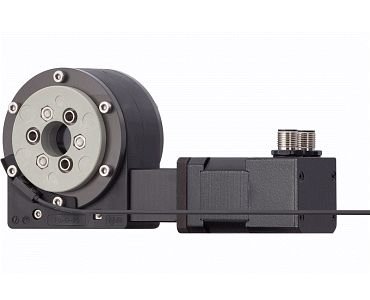

Strain wave gear

- Compact, quiet and efficient

- Areas of application: precise motion transmission, low torques

- Suitable for: small robot arms

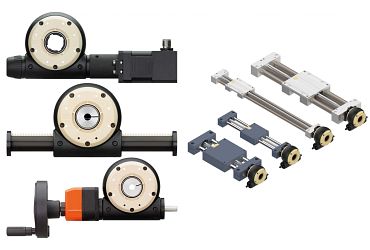

Worm gears

- Robust and long-lasting

- Areas of application: high torques, slow movement, secure position holding

- Suitable for: Conveyor technology, robotics, lifting systems, part-turn actuators

Rotary axis with motor

- Compact and easy to install

- Areas of application: 360° movement

- Suitable for: Turntables for mounting applications, camera panning in photography

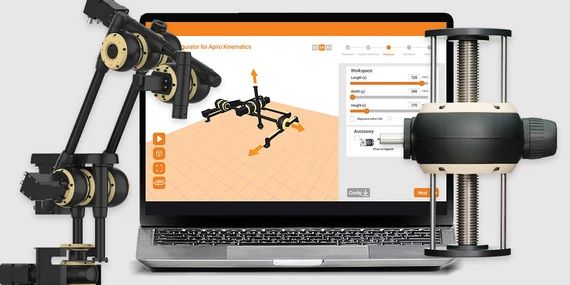

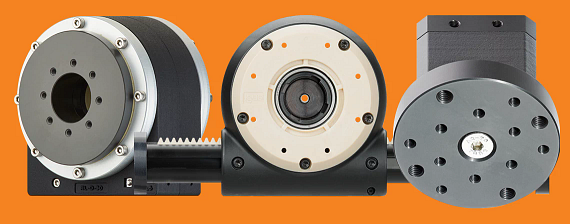

Apiro®, the modular gearbox system

- Modular lightweight construction

- Areas of application: wide range of requirements, flexibility in design

- Suitable for: Automation, robotics, industry, manual and motorised drives

Planetary gearbox

- High transmission ratios

- Areas of application: high torques in a compact design

- Suitable for: CNC machines, robotics, packaging machines

Other gearboxes and drive components

Discover our wide range of high-quality solutions for industrial systems and robotics applications. Optimise the performance of your application with our gearbox technology!

Information material

Would you like digital information material for format adjustment in the beverage and packaging industry?Download checklist

Do you have a specific use case and would like advice on it? Fill in the checklist now!

Return telephone call

Would you like to get in touch with an expert and receive a return telephone call within 24 hours?Our new gearbox products in 2024

▶ Discover now

Advantages of the drygear® gearbox technology

Cost-effective

Manufacturing with injection moulding or 3D printing guarantees cost efficiency and creates the geometrical freedom to optimise use of installation space. The flexible modular system allows the gearboxes to be expanded as desired and integrated into existing systems.

Lubrication and maintenance-free

Sustainable

Quiet

Thanks to motion plastics®, drygear® plastic gearboxes impress with ultra-light materials. This results in much less noise and vibration. For you as an operator, plastic gears - for example in robots - lead to an application that is up to four times quieter.

Temperature-resistant

Tested and proven

Apiro® configurator

Kinematics tailored to your needs

Enter your requirements into the Apiro® modular gearbox system online configurator and receive an application overview. The input can be queried as an offer, or you can easily download your configuration as a CAD file.- Fast and easy configuration

- Optional accessories such as motors and motor control systems

- Fast delivery (ready to ship starting in 24 hours)

Application examples for gearbox technology

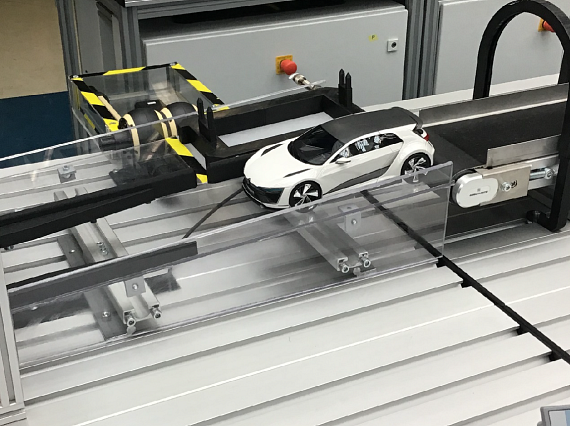

VW Golf production at a 1:18 scale for trainees

In their vocational training at Volkswagen AG in Wolfsburg, Germany, trainees from various departments work on simulating VW Golf delivery at a 1:18 scale.

The smart factory consists of twelve individual stations that, when pushed together, form two parallel production lines.

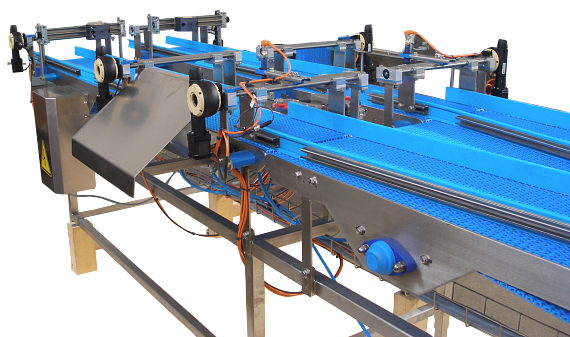

Format adjustment in the packaging industry

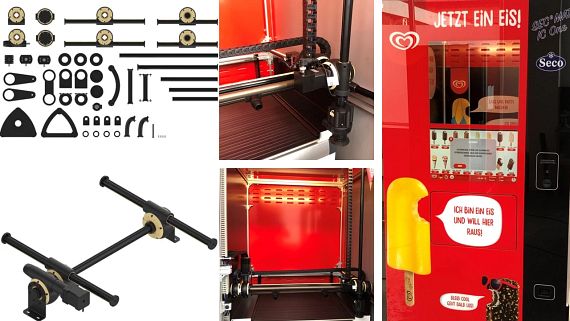

Successful use of the conveyor belt with drygear® Apiro® gearboxes

How innovative technology handles the challenges of transporting food packaging and allows flexible format adjustment for product channelling with igus® drygear® Apiro® gearboxes.

Low-cost components for astrophotography

vhw Digitalart has developed a device that compensates for the Earth's rotation in order to image celestial bodies in their real form. The requirements for the plastic gearbox were a rotation of 360 degrees in exactly 24 hours, enough load capacity to support the camera and its lens, and high individual component strength and abrasion resistance.

low-maintenance gearbox solution and energy supply systems in an ice cream vending machine

More application examples

Automated format adjustment for the packaging and beverage industry

Easy handling - operated manually or automatically

Einfach, schnell und unkompliziert Formatverstellungen durchführen. Mit dem modularen Apiro® Getriebebaukasten, können Sie durch verschiedene Übersetzungen, aber auch Längenvarianten, Ihre passende Gassenverstellung aufbauen.Apiro® iDeas

Ideas for automation solutions.Select an automation solution – Download parts lists and CAD data!

Low Cost Automation Applications

More than 8,000 individual solutions per year!Select your industry or application and learn more about our customers' success stories.